Hasung - 220V 1kg 2kg Mini Automatic Vacuum Pressure Casting Machine For Gold Silver Jewelry Casting

Innovation is a factor in the long-term quality assurance of 220V 1kg Mini Automatic Vacuum Pressure Casting Machine For Gold Silver Jewelry Casting.The measured data indicates that products meets the market requirements.In additon,we can customize size, shape or color to suit the specific need of our customers.

HS-VTC3

As a quality-driven and customer-oriented enterprise,Shenzhen Hasung Precious Metals Equipment Co., Ltd always guarantees our development work involves the creative design and meticulous production. Our 220V 1kg Mini Automatic Vacuum Pressure Casting Machine For Gold Silver Jewelry Casting is expected to catch wide attention. Since launched, 220V 1kg Mini Automatic Vacuum Pressure Casting Machine For Gold Silver Jewelry Casting has been receiving mounting acclaim from customers. Shenzhen Hasung Precious Metals Equipment Co., Ltd will always stick to the business principle of 'quality first, customers foremost' and strive towards building an even more competitive and capable company aiming for an even better future.

The First-Class Level Quality and Technology for Precious Metals Equipment Manufacturer in China.

Customers got a real answer to know why our machines are the best. Energy saving, speedy melting, accurate temperature control, saving argon, super high degree vacuum tightness, super perfect gold bar results, etc.

Specification

|

Model No.

|

HS-VCT1

|

HS-VCT2

|

|

Voltage

|

220V / 380V, 50/60Hz

|

220V / 380V, 50/60Hz

|

|

Power

|

8KW

|

10KW

|

|

Maximum temperature

|

1500°C

|

|

|

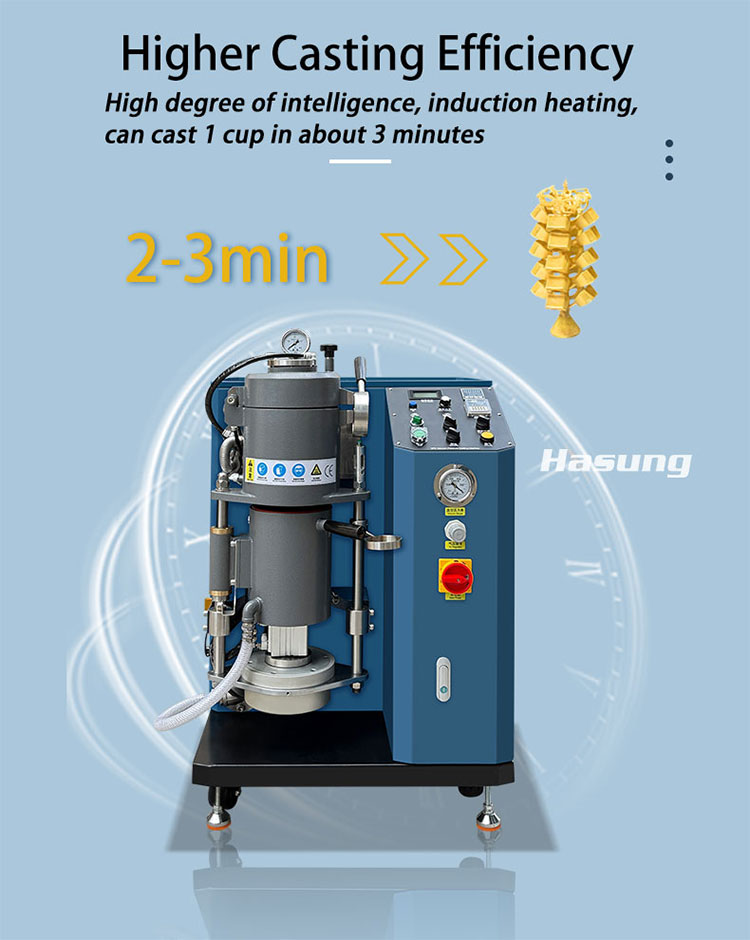

Melting speed

|

1-2 min.

|

2-3 min.

|

|

Casting pressure

|

0.1Mpa - 0.3Mpa (adjustable)

|

|

|

Capacity (Gold)

|

1kg

|

2kg

|

| Max. cylinder size | 4"x10" 5"x10" | |

|

Application metals

|

Gold, K gold, Silver, Copper, alloy

|

|

|

Operation method

|

One-key operation to complete the entire process, POKA YOKE foolproof system

|

|

| Control system |

Taiwan / Siemens PLC+Human-machine interface intelligent control system (optional)

|

|

| Operation mode | Automatic mode / Manual mode (both) | |

|

Protection gas

|

Nitrogen/argon selection

|

|

|

Cooling type

|

Running water / Water chiller (Sold separately)

|

|

|

Vacuum pump

|

High performance vacuum pump (included)

|

|

|

Dimensions

|

780*720*1230mm

|

|

|

Weight

|

Approx. 230kg.

|

|

Product Description

Steps for Casting Jewelry via the Vacuum Pressure Jewelry Casting Equipment

1.The first step is to prepare the wax molds. It's advisable you weld the wax molds into a wax mold tree (the wax molds can be copied in batches by a wax injection machine or printed by a 3D printer).

2.Make a lost wax casting mold with a vacuum powder mixer.

3.Use a wax burnout furnace in melting the wax out of the mold.

4.Melt the precious metal and fill the entire gypsum of the vacuum pressure casting equipment.

5.The rough piece of the Jewelry is formed after the melted wax cools.

6.Remove the excess plaster with a plaster cleaning machine, and you are good to market your Jewelry.

You can bank with Hasung to provide you with a one-stop production line solution for jewelry casting. The production package ranges from on-site guidance, equipment, and engineers to help you scale through the process.

Hasung is committed to solving your casting problems while proffering step by step guide to precious metals. We have been at the

forefront of the Jewelry casting industry for 20+ years. We possess professional and meticulous engineers’, on-site training

service, and a casting experience of more than ten years.

Hasung has helped build dozens of jewelry casting production lines in places like India, Dubai, Australia, Qatar, etc. Our

engineers have rich experience in crafting a complex and unique piece of Jewelry.

Hasung Precious Metals Equipment advantages:

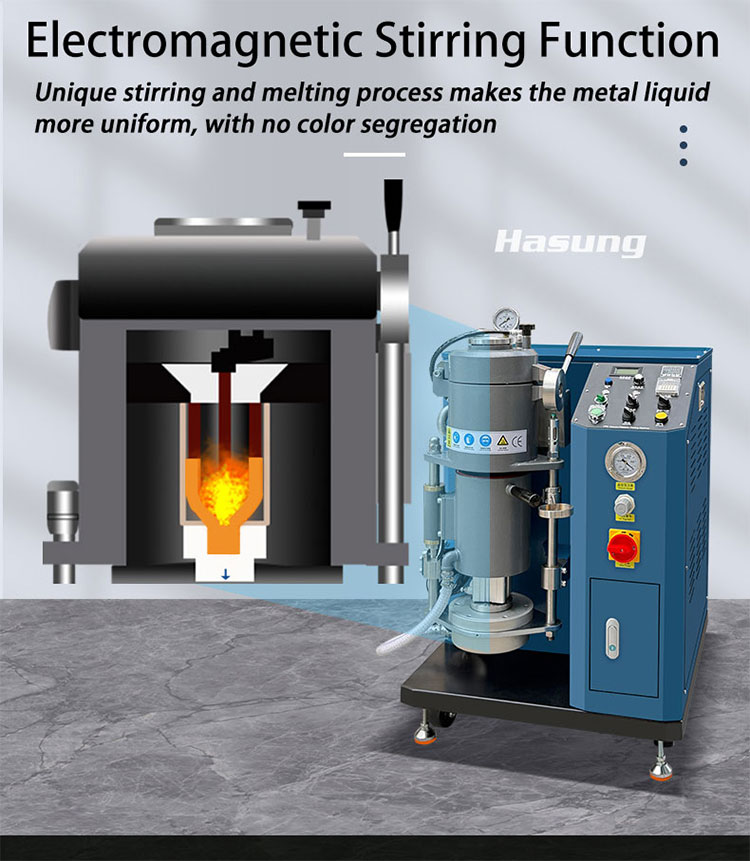

1.The product has uniform color and no segregation:

The porosity is reduced, and the density is higher and constant, reducing post-processing work and reducing loss.

2.Better material fluidity and mold filling, lower enthusiasm risk:

Vibration improves material flow, and the material structure is more compact. Improve shape filling and reduce the risk of hot cracks.

3.The grain size is reduced to 50%:

Solidify with a finer and more uniform structure

4.Better and more stable material properties:

The tensile strength and elasticity are increased by 25%, and the subsequent processing performance is improved.

Why do You Choose Hasung Vacuum Pressure Casting Machine ?

Hasung Vacuum Casting machines compare to other companies.

Hasung's original parts are from well-known domestic Japan and German brands to ensure the first-class level quality.

Water chiller for cooling induction metal casting machines.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and

casting equipment, especially for high tech vacuum and high vacuum casting machines.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115