TVC Induction Casting Machine Gold Jewellery Vacuum Pressure Casting Machine with Vibration Technology

Hasung Touch Panel Vibration System TVC induction casting machine has obtained unanimous favorable comments from market.The quality assurance of it can be achieved with certification.Moreover,to take care of different needs, product customization is provided.

5.0

Customization:

Customized logo (Min. Order: 1 pieces),Customized packaging (Min. Order: 1 pieces),Graphic customization (Min. Order: 1 pieces)

shipping:

Express Sea freight · Land freight · Air freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

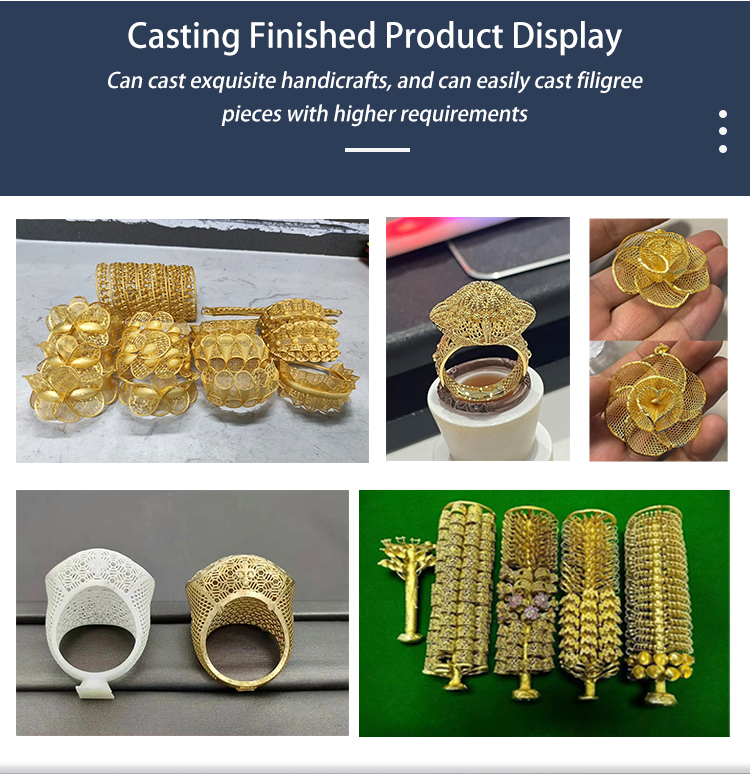

Your next machine for casting jewellery.

Max. withstand 4 bars pressure which gurantees perfect casting. Vacuum sealing with SBS system, without using gaskets.

Technical data

| Model No. | HS-TVC1 | HS-TVC2 | ||

| Voltage | 220V, 50/60Hz 1 Ph | 380V, 50/60Hz 3 Ph | ||

| Power | 8KW | 10KW | ||

| Max. temp. | 1500°C | |||

| Melting speed | 1-2 min | 2-3 min | ||

| Casting pressure | 0.1Mpa - 0.3Mpa | |||

| Capacity (Gold) | 1kg | 2kg | ||

| Max. cylinder size | 4"x10" | 5"x10" | ||

| Application metals | Gold, K gold, Silver, Copper, alloy | |||

| Vacuum pressure setting | Available | |||

| Argon pressure setting | Available | |||

| Temperature setting | Available | |||

| Pouring time setting | Available | |||

| Pressure time setting | Available | |||

| Pressure hold time setting | Available | |||

| Vacuum time setting | Available | |||

| Vibration time setting | Available | |||

| Vibration hold time setting | Available | |||

| Program for flask with flange | Available | |||

| Program for flask without flange | Available | |||

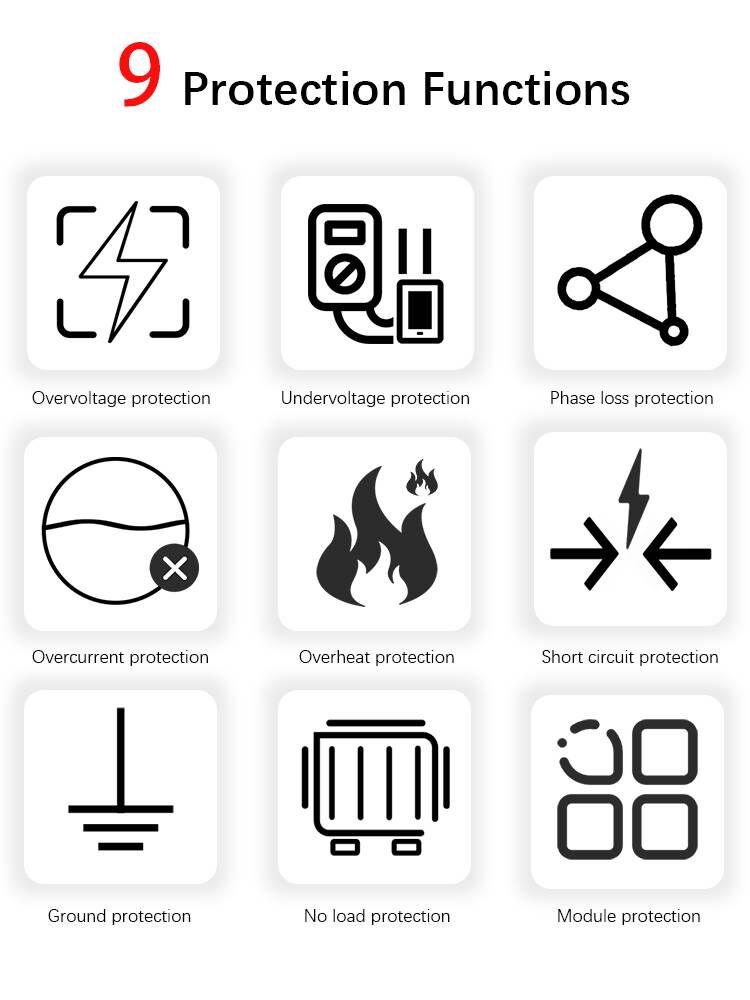

| Overheat protection | Yes | |||

| Magnetic stirring function | Yes | |||

| Flask lifting height adjustable | Available | |||

| Different flask diameter | Available, using different flanges | |||

| Operation method | One-key operation to complete the entire casting process, manual mode is optional | |||

| Control system | Taiwan Weinview touch screen + Siemens PLC | |||

| Operation mode | Automatic mode / Manual mode (both) | |||

| Inert gas | Nitrogen/argon (optional) | |||

| Cooling type | Running water / Water chiller (Sold separately) | |||

| Vacuum pump | High performance vacuum pump (optional) | |||

| Dimensions | 880x680x1230mm | |||

| Weight | approx. 250kg | approx. 250kg | ||

| Packing size | casting machine: 88x80x166cm, vacuum pump: 61x41x43cm | |||

| Packing weight | approx. 290kg. (vacuum pump included) | approx. 300kg. (vacuum pump included) | ||

2 Years Warranty

Automatic Technology Advantages

1. The product has uniform color and no segregation:

The porosity is reduced, and the density is higher and constant, reducing post-processing work and reducing loss.

2. Better material fluidity and mold filling, lower enthusiasm risk:

Vibration improves material flow, and the material structure is more compact. Improve shape filling and reduce the risk of hot cracks

3. The grain size is reduced to 50%:

The porosity is reduced, and the density is higher and constant, reducing post-processing work and reducing loss.

2. Better material fluidity and mold filling, lower enthusiasm risk:

Vibration improves material flow, and the material structure is more compact. Improve shape filling and reduce the risk of hot cracks

3. The grain size is reduced to 50%:

Solidify with a finer and more uniform structure

4. Better and more stable material properties:

The tensile strength and elasticity are increased by 25%, and the subsequent processing performance is improved.

4. Better and more stable material properties:

The tensile strength and elasticity are increased by 25%, and the subsequent processing performance is improved.

Details Images

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

CONTACT US

Contact Person: Jack Heung

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115

Copyright © 2025 Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd | Sitemap | Privacy Policy