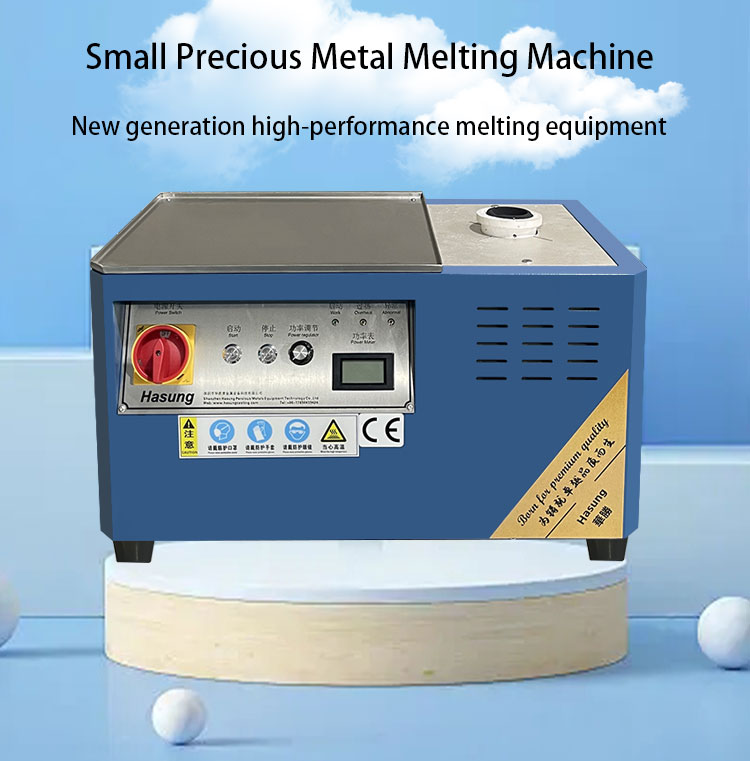

Quality Hasung 4kg Small Induction Melting Machine Manufacturer | Hasung

Hasung 4kg Small Induction Melting Machine compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Hasung summarizes the defects of past products, and continuously improves them. The specifications of Hasung 4kg Small Induction Melting Machine can be customized according to your needs.

5kw 220v 1-2kg platinum gold melting/smelting oven for metal processing is a good example to showcase our research and development capability. If you are interested in our products, welcome to contact us, we are very happy to serve you!

Model No.: HS-GQ4

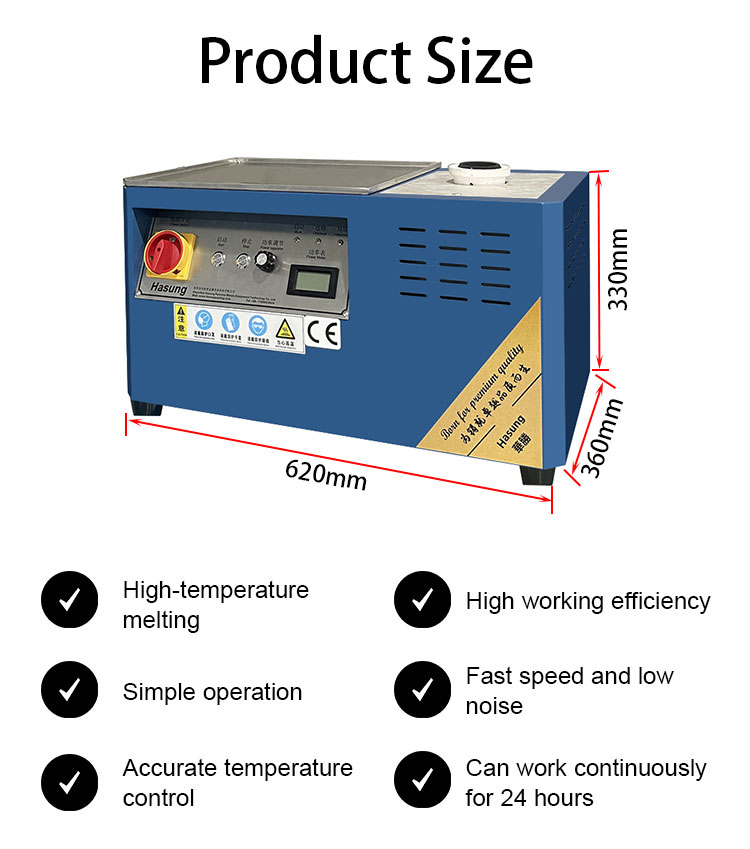

Product Technical Specification:

| Model No. | HS-GQ3 | HS-GQ4 |

| Voltage | 220V, 50/60Hz, single phase | |

| Power | 8KW | |

| Capacity (Au) | 3kg | 4kg |

| Application metals | Gold, silver, copper, Zinc, alloys | |

| Melting speed | approx. 2-4 Min. | approx. 4-6 Min. |

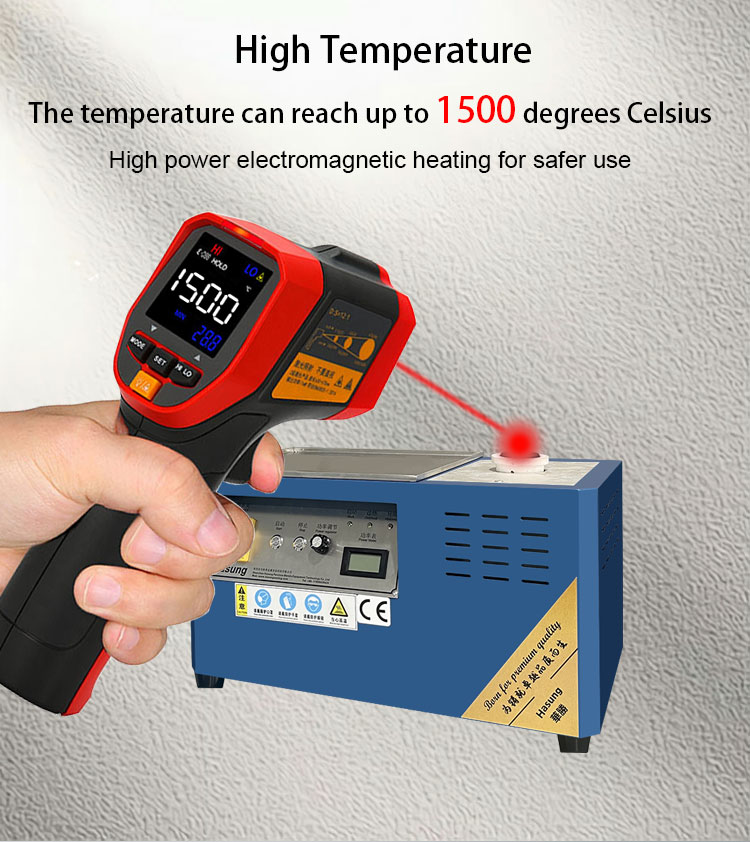

| Max. temperature | 1500°C | |

| Temperature detector | available | |

| Cooling method | Water cooling (Water pump) | |

| Dimensions | 65x36x34cm | |

| Weight | approx. 30kg | |

Product details:

Company Advantages

Our machines enjoy two years warranty.

More than 30 patents for machines.

Our factory has passed the ISO 9001 international quality certification

It is extensively used in precious metals refining, precious metals smelting, precious metals bars, beads, powders trading, gold jewellery, etc.

Small induction melting furnace with a capacity of 4 kg: advantages and disadvantages

In metal processing and casting operations, the use of small induction melting furnaces with a capacity of 4 kg is becoming increasingly popular. These compact and efficient furnaces offer businesses and hobbyists a range of benefits and advantages. There are many reasons why investing in a small induction furnace with a 4kg capacity may be a smart decision, from the ability to melt a variety of metals to energy efficiency and ease of use. In this article, we will explore the advantages of these furnaces and why they are a valuable asset to anyone involved in the metal melting and casting process.

1. Versatility in melting different metals

One of the main advantages of a small induction melting furnace with a capacity of 4 kg is its ability to melt different types of metals. Whether you are working with precious metals like gold and silver, or non-ferrous metals like copper and aluminum, these furnaces are capable of handling a variety of materials. This versatility makes them ideal for jewelry making, small metal casting, and a variety of industrial applications that require melting small amounts of metal.

2. Energy efficiency

Small induction melting furnaces are known for their energy efficiency, making them a cost-effective choice for metal melting operations. Using induction heating minimizes heat loss because the energy is transferred directly to the metal being melted. This not only reduces energy consumption but also contributes to a more sustainable and environmentally friendly melting process.

3. Compact, space-saving design

The compact size of small induction melting furnaces makes them an attractive option for businesses and hobbyists with limited space. Whether used in a small workshop or as part of a larger industrial facility, these furnaces can be easily integrated into existing workspaces without extensive modifications. Its space-saving design allows efficient use of floor space while still providing the power needed to melt small batches of metal.

4. Fast melting speed and high productivity

With rapid heating capabilities, small induction melting furnaces provide fast melting times, resulting in increased productivity and output. This is especially beneficial for businesses that require quick turnaround times and efficient production processes. The ability to melt metal quickly and consistently can have a significant impact on overall operational efficiency and throughput.

5. Clean and safe operations

Induction melting technology provides a clean, safe operation compared to traditional melting methods such as gas or oil furnaces. The absence of open flames and combustion processes reduces the risk of workplace accidents and minimizes the release of harmful emissions. In addition, the enclosed design of the induction furnace helps contain smoke and prevent metal splash, creating a safer working environment for operators.

6. Easy to use and maintain

Small induction melting furnaces are designed to be easy to use and maintain, making them suitable for a variety of users, from experienced professionals to beginners in the field of metal casting. Its simple controls and user-friendly interface allow for intuitive operation, while its durable construction and minimal moving parts help reduce maintenance requirements.

7. Cost-effective small melting solution

For businesses and individuals looking for a cost-effective small-scale metal melting solution, the 4kg capacity induction furnace offers an attractive option. Its relatively low initial investment, coupled with its energy efficiency and versatility, makes it a practical choice for those who need a compact and reliable melting solution without the need for large equipment.

In conclusion, the benefits of investing in a small induction melting furnace with a capacity of 4 kg are manifold. From versatility in melting different metals to energy efficiency, compact design, and ease of use, this type of furnace offers a range of advantages for metalworking and casting operations. Whether used for jewelry making, small-scale production, or industrial applications, these furnaces provide valuable resources for the melting and casting process. With their ability to provide precise temperature control, fast melting times, and clean and safe operation, they have become an indispensable tool for anyone involved in metal melting and casting.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115