Yuav ua li cas ua cov hniav nyiaj hniav kub nrog lub tshuab kub casting?

Kub casting tshuab hniav nyiaj hniav kub ua

Kawm txog kub casting

Kub casting yog ib txoj hauv kev ua cov hniav nyiaj hniav kub los ntawm kev nchuav kub rau hauv pwm. Lub tshuab no ua rau cov qauv tsim thiab cov duab uas nyuaj rau kev ua tiav nrog cov txheej txheem ib txwm muaj. Lub tshuab kub casting automates ntau ntawm cov txheej txheem, ua rau nws siv tau rau ob qho tib si jewelers thiab amateurs.

Hom kub casting tshuab

Ua ntej delving rau hauv cov txheej txheem ua hniav nyiaj hniav kub, nws yog ib qho tsim nyog yuav tsum nkag siab txog ntau hom kub casting tshuab muaj:

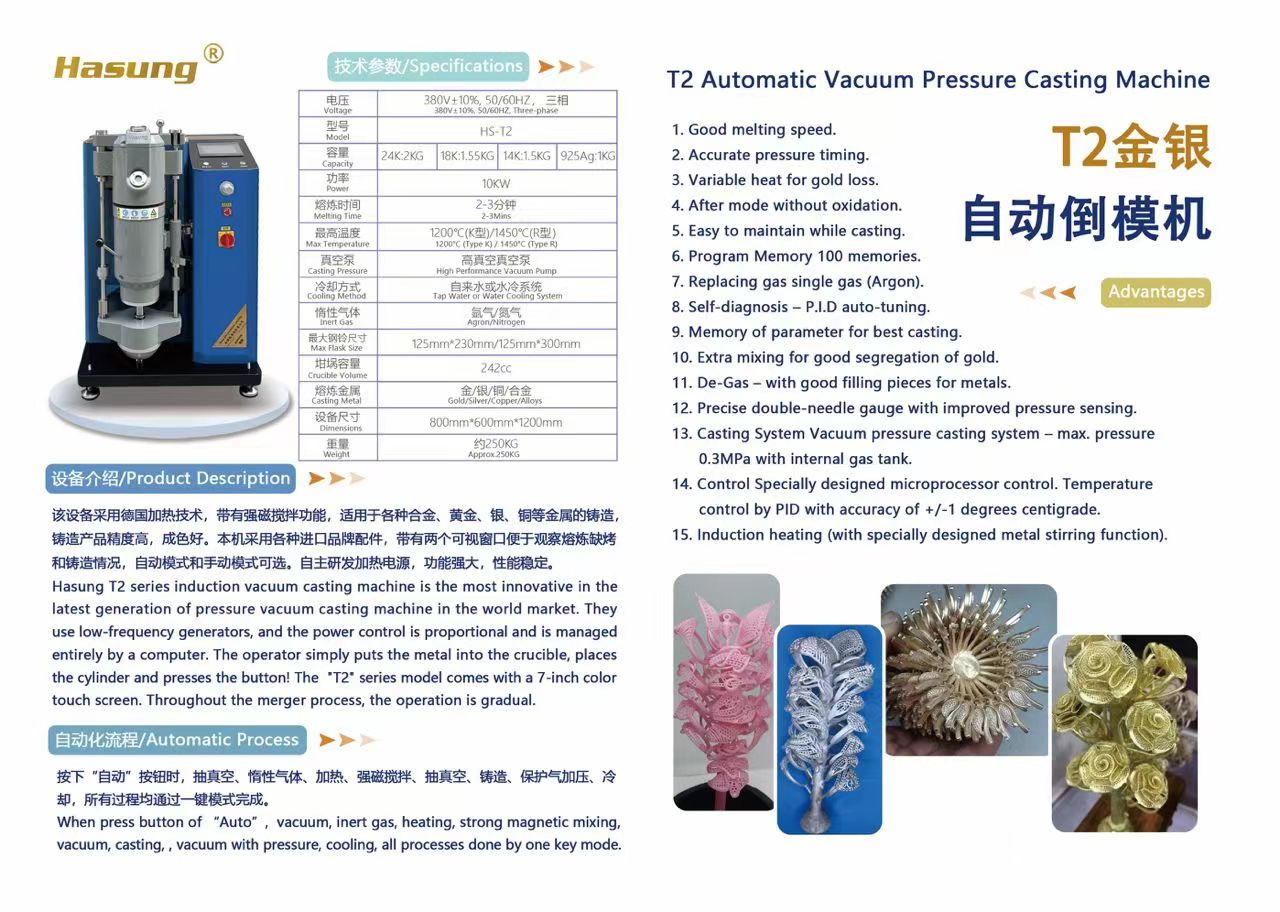

Induction Casting Tshuab: Cov tshuab no siv electromagnetic induction kom kub kub, tso cai rau kev tswj qhov kub thiab txias. Lawv yog cov zoo tagnrho rau cov me me ntau lawm thiab complex designs.

Nqus Casting Tshuab: Cov tshuab no tsim lub tshuab nqus tsev ib puag ncig los tiv thaiv npuas los ntawm kev sib sau hauv cov kub kub. Qhov no yog tshwj xeeb tshaj yog pab tau rau cov ncauj lus kom ntxaws designs thiab kom ib tug du nto.

Centrifugal Casting Tshuab: Cov tshuab no siv lub zog centrifugal los thawb kub kub rau hauv pwm. Txoj kev no zoo heev rau kev tsim cov haujlwm ntxaws ntxaws thiab feem ntau siv rau hauv ntau lawm.

Yuav tsum tau cov cuab yeej thiab cov khoom siv

Txhawm rau pib ua cov hniav nyiaj hniav kub nrog lub tshuab kub casting, koj yuav xav tau cov cuab yeej thiab cov ntaub ntawv hauv qab no:

· Kub Casting Tshuab: Xaiv lub tshuab uas haum rau koj cov kev xav tau thiab kev siv nyiaj txiag.

· Wax Mockup: Qhov no yog thawj zaug tsim ntawm cov hniav nyiaj hniav kub, feem ntau yog ua los ntawm wax.

· Cov Khoom Siv Peev Xwm: Kev sib xyaw ntawm silica thiab lwm yam khoom siv los ua pwm.

· Burnout Rauv: Lub cub tawg no yog siv los yaj cov qauv siv quav ciab, tawm hauv cov kab noj hniav rau cov kub.

· Molten Gold: Koj tuaj yeem siv cov khoom kub lossis kub alloy, nyob ntawm qhov koj xav tau.

· Cov Khoom Siv Tiv Thaiv Kev Nyab Xeeb: Ib txwm hnav cov khoom tiv thaiv nrog rau hnab looj tes, tsom iav thiab daim npog ntsej muag

Step-by-step qhia ua cov hniav nyiaj hniav kub

Kauj Ruam 1: Tsim koj cov hniav nyiaj hniav kub

Thawj kauj ruam hauv kev tsim cov hniav nyiaj hniav kub yog tsim koj daim. Koj tuaj yeem kos duab koj tus qauv tsim rau ntawm daim ntawv lossis siv computer-aided design (CAD) software kom pom tseeb dua. Xav txog qhov loj me, cov duab thiab cov ntsiab lus ntawm koj daim ntawv vim cov no yuav cuam tshuam rau cov qauv siv quav ciab koj tsim.

Kauj Ruam 2: Tsim cov qauv siv quav ciab

Tom qab ua tiav qhov tsim, cov kauj ruam tom ntej yog los tsim cov qauv siv quav ciab. Koj tuaj yeem sculpt tus qauv ntawm tes los yog siv lub tshuab luam ntawv 3D rau kev tsim ntau dua. Cov qauv siv quav ciab yuav tsum yog qhov tseeb ntawm qhov kawg nkaus vim nws yuav ua lub hauv paus rau pwm.

Kauj Ruam 3: Npaj cov pwm

Tom qab tsim cov qauv siv quav ciab, nws yog lub sijhawm los npaj cov pwm. Muab tus qauv siv quav ciab tso rau hauv lub khob thiab sau nrog cov khoom siv peev. Tso cai rau cov khoom siv peev txheej raws li cov chaw tsim khoom cov lus qhia. Thaum hardened, lub hwj yog muab tso rau hauv ib lub qhov cub burnout kom yaj cov quav ciab, tawm hauv kab noj hniav nyob rau hauv cov khoom peev.

Kauj Ruam 4: Melt tus kub

Thaum cov wax hlawv tawm, npaj koj cov kub. Muab cov kub tso rau hauv lub tshuab kub casting thiab teeb qhov kub kom haum. Lub melting point ntawm kub yog kwv yees li 1,064 degrees Celsius (1,947 degrees Fahrenheit), yog li xyuas kom tseeb tias koj lub tshuab tau teem kom ncav cuag qhov kub no.

Kauj Ruam 5: Ncuav Kub

Thaum cov kub yaj thiab cov wax tshem tawm, cov kub yog nchuav rau hauv pwm. Yog tias koj siv lub tshuab centrifugal casting, muab lub khob ntim rau hauv lub tshuab thiab pib ncuav kub. Rau lub tshuab nqus tsev casting, nco ntsoov tsim lub tshuab nqus tsev ua ntej nchuav kub kom tsis txhob muaj cua npuas.

Kauj Ruam 6: Txias thiab ua kom tiav

Tom qab nchuav kub, cia cov pwm kom txias tag. Cov txheej txheem no tuaj yeem siv sijhawm nyob qhov twg los ntawm ob peb feeb mus rau ob peb teev, nyob ntawm qhov loj ntawm workpiece. Tom qab txias, cov ntaub ntawv peev yog ua tib zoo muab tshem tawm kom nthuav tawm cov casting.

Kauj Ruam 7: Ntxuav thiab Polish

Cov kauj ruam kawg hauv kev tsim cov hniav nyiaj hniav kub yog ntxuav thiab polishing koj daim. Siv cov menyuam los yog cov ntaub polishing kom tshem tawm cov npoo ntxhib thiab coj tawm qhov ci ntawm koj cov hniav nyiaj hniav kub. Koj tuaj yeem xav ntxiv lwm cov ntsiab lus, xws li gemstones lossis engravings, los txhim kho koj tus qauv tsim.

Secrets to Successful Jewelry Making

Xyaum Kev Nyab Xeeb: Ib txwm muab kev nyab xeeb ua ntej thaum ua haujlwm nrog cov hlau molten. Xyuas kom tseeb tias koj qhov chaw ua haujlwm yog qhov cua zoo thiab tsis muaj cov khoom siv hluav taws xob.

Kev sim tsim: Tsis txhob ntshai sim cov qauv tsim thiab cov tswv yim sib txawv. Qhov ntau koj xyaum, koj yuav ua tau zoo.

Kev nqis peev hauv Cov Cuab Yeej Zoo: Cov cuab yeej zoo thiab cov khoom siv tuaj yeem cuam tshuam loj rau cov khoom kawg. Ua lag luam nyob rau hauv ib tug txhim khu kev qha kub casting tshuab thiab zoo peev ntaub ntawv.

Koom Nrog Lub Zej Zog: Xav txog kev koom nrog lub zej zog ua cov hniav nyiaj hniav kub los yog kawm hauv chav kawm los ntawm cov kws ua haujlwm paub txog. Kev sib qhia kev paub thiab kev paub dhau los tuaj yeem txhim kho koj qhov kev txawj ntse.

Kev Kawm Txuas Ntxiv: Lub ntiaj teb ntawm kev tsim cov hniav nyiaj hniav kub yog qhov loj thiab hloov mus ib txhis. Nyob twj ywm paub txog cov thev naus laus zis tshiab, cov cuab yeej thiab cov qauv tsim los txhim kho koj cov khoom siv tes ua tsis tu ncua.

nyob rau hauv xaus

Ua cov hniav nyiaj hniav kub nrog lub tshuab kub casting yog txheej txheem zoo siab thiab muaj txiaj ntsig. Los ntawm kev ua raws li cov kauj ruam uas tau teev tseg hauv tsab xov xwm no, koj tuaj yeem tsim cov khoom zoo nkauj thiab zoo nkauj uas qhia txog koj tus kheej style. Txawm hais tias koj yog ib tus neeg paub txog jeweler lossis ib tus pib, lub tshuab kub casting qhib lub ntiaj teb muaj peev xwm ua cov hniav nyiaj hniav kub. Txais kev kos duab, sim nrog kev tsim, thiab cia koj lub tswv yim ci ntsa iab!

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115