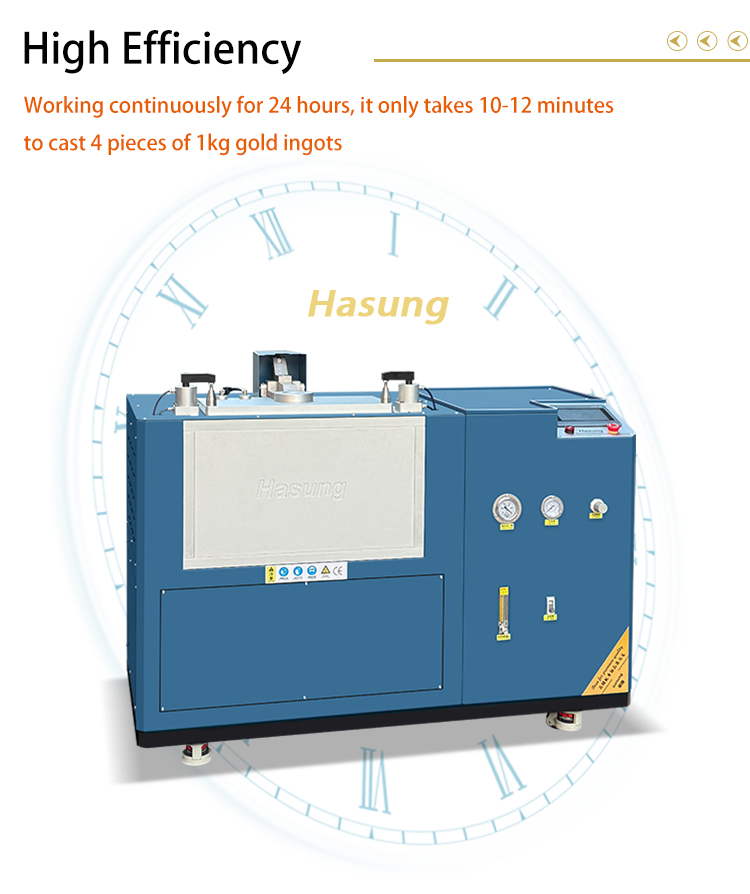

Tag Nrho Tsis Siv Neeg 4KG Kub Bullion Bar Ua Casting Rauv Tshuab rau muag

Hasung Tag Nrho Tsis Siv Neeg Kub Bar Ua Tshuab yog cov khoom siv zoo casting rau precision casting kub tuav, ingots, thiab bullion. Muaj nyob rau hauv 1KG (HS-GV1) thiab 4KG (HS-GV4) qauv, qhov kub bar ntau lawm tshuab integrates advanced nqus casting tshuab nrog ntse automation kom xa tau flawless. Tsim los rau kev ua tau zoo, raug, thiab cov neeg siv khoom siv tau zoo, nws yog qhov zoo tagnrho rau cov chaw tsim khoom, cov chaw ua haujlwm hniav nyiaj hniav kub, thiab cov neeg tsim khoom kub.

Cov yam ntxwv tseem ceeb:

1.Ua haujlwm tsis siv neeg puv:

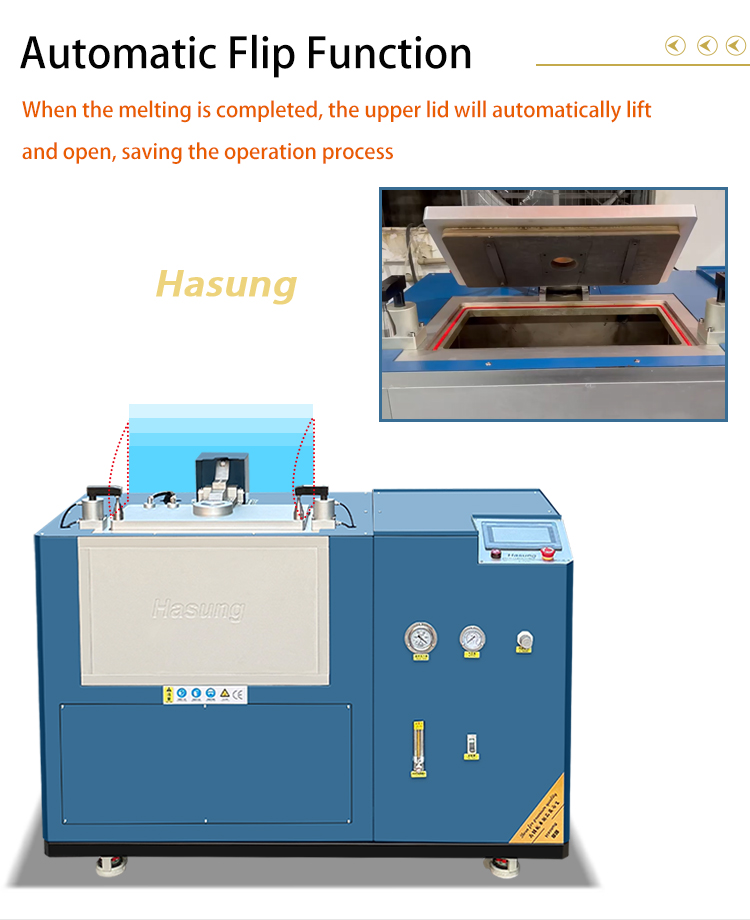

Ib-kov tswj rau melting, pouring, thiab cua txias mus.

Txo cov nqi zog thiab txo qis tib neeg kev ua yuam kev.

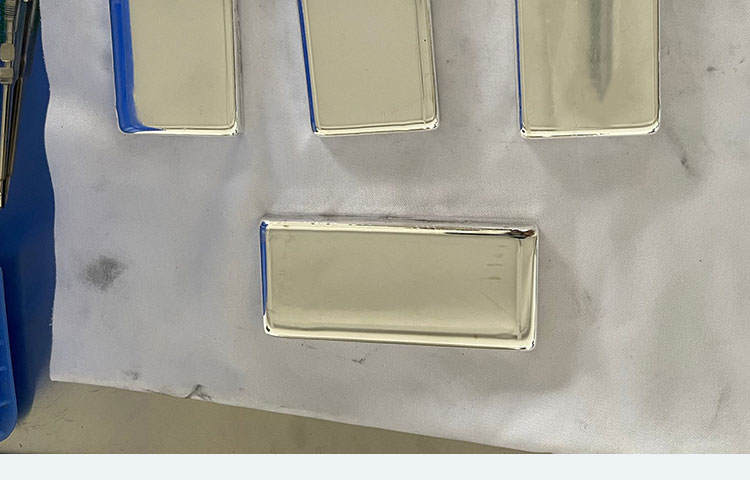

2.Nqus Casting Technology:

Tshem tawm oxidation thiab impurities, kom ntseeg tau siab-purity kub tuav.

Zoo tagnrho rau 999.9 zoo kub (24K) casting.

3.Precision Temperature Control:

± 1 ° C raug nrog PID tswj cov cua sov.

Xyuas kom uniform melting thiab pouring.

4.Energy-Efficient Design:

Optimized cua sov cycles txo hwj chim noj.

5.Intelligent Control System:

PLC-based touchscreen vaj huam sib luag rau kev teeb tsa qhov tseeb thiab kev saib xyuas lub sijhawm.

Structure & Cheebtsam:

Nqus Chamber: Hermetically kaw stainless hlau siv nrog dual-txheej rwb thaiv tsev.

Induction Cua sov System: High-frequency induction coil rau ceev thiab zoo melting.

Pwm & Pouring Mechanism: Tilting system rau cov hlau nchuav hauv lub tshuab nqus tsev.

Intelligent Control Vaj Huam Sib Luag: Real-time data logging rau traceability thiab zoo tswj.

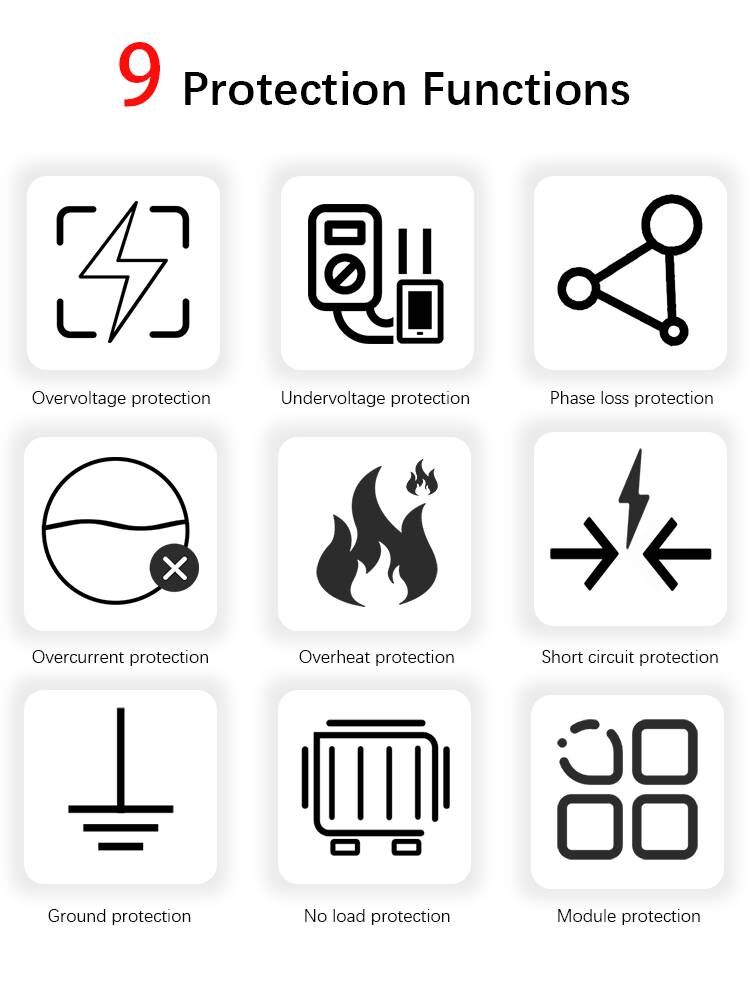

Kev Nyab Xeeb Nta: Kev tiv thaiv overheat, nres thaum muaj xwm ceev, thiab lub tshuab nqus tsev vacuum.

Technical Secifications:

Kub Bar Ua Tshuab / Nqus Kub Ingot Casting Tshuab nrog 10 "PLC Display controller system.

| Qauv No. | HS-GV4 |

| Qhov hluav taws xob | 380V, 50/60Hz 3 Phase |

| Hwj chim | 50KW |

| Casting lub sij hawm | 10-12 feeb. |

| Peev xwm (Au) | 4kg (4 pcs 1kg, 16pcs 100g lossis ntau dua.) |

| Max kub | 1500 ° C |

| Kev siv hlau | Kub, Nyiaj |

| Inert gas | Argon / Nitrogen |

| Dej txias txias | 20-26 ° C |

| Lub tshuab nqus tsev twj | Kev ua haujlwm siab tus nqi nqus tsev vacuum (nrog) |

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem casting |

| Hom cua txias | Dej chiller (muag nyias) los yog dej ntws |

| Tswj system | 7" Siemens kov npo + Siemens PLC tswj qhov system |

| Qhov ntev | 1460 * 720 * 1010 hli |

| Qhov hnyav | kwv yees. 3 80kg |

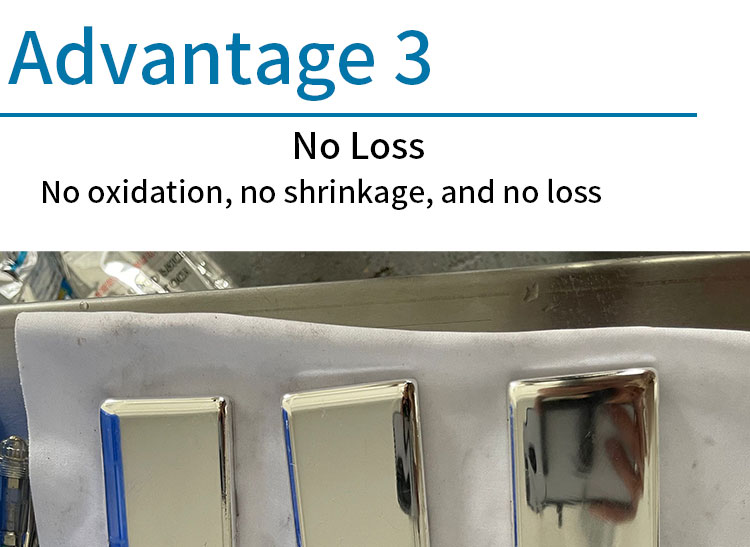

Qhov zoo:

Hasung tsis siv neeg kub bar casting tshuab nruab nrog lub xeev-of-the-art technology, lub xeev-of-the-art tshuab no muaj tag nrho automated lag luam rau seamless thiab npaum kub bar casting. Nrog nws cov precision engineering thiab txiav-ntug nta, lub tshuab muab flawless casting tshwm sim, ua sparkling, flawless kub tuav ntawm zoo tshaj plaws.

1.Lub tshuab kub tsis siv neeg casting yog tsim los ua kom tau raws li cov kev xav tau ntawm niaj hnub kub refining thiab raug txheej txheem. Nws txoj kev ua haujlwm automated streamlines txheej txheem casting, tshem tawm qhov xav tau ntawm phau ntawv kev cuam tshuam thiab ua kom cov txiaj ntsig zoo ib yam thiab meej txhua lub sijhawm. Qhov no tsis tsuas yog nce kev tsim khoom tab sis kuj txo cov npoo ntawm qhov yuam kev, ua rau nws yog ib qho khoom siv tseem ceeb rau cov khoom siv kub kub.

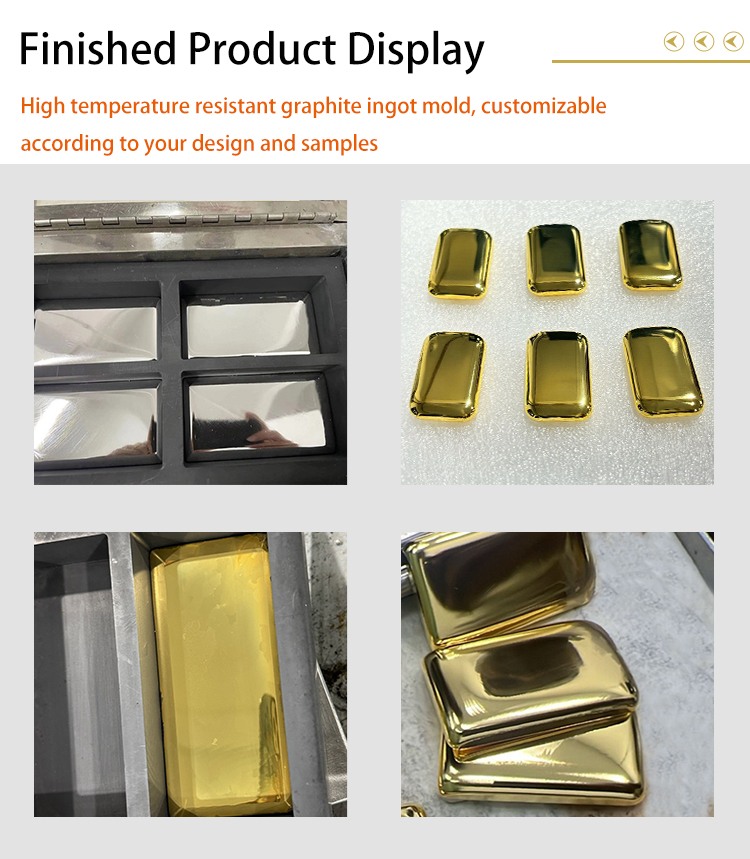

2.Ib lub ntsiab tseem ceeb ntawm lub qhov cub kub no yog nws lub peev xwm los tsim cov khoom ci ci nrog cov nplaim zoo kawg nkaus. Advanced casting technology xyuas kom meej tias cov kub tuav tsis muaj qhov tsis xws luag xws li npuas lossis deg irregularities, uas ua rau lub pristine thiab lustrous apearance. Qhov kev ua tau zoo no yog qhov tseem ceeb rau kev ua kom tau raws li cov qauv kev lag luam kub thiab ua tau raws li qhov kev cia siab ntawm cov neeg siv khoom txaus siab.

3.Lub tshuab nqus tsev kub tsis siv neeg lub tshuab nqus tsev casting yog tsim los muab cov neeg siv kev paub dhau los, nrog kev tswj xyuas qhov tseeb thiab tus neeg siv interface uas yooj yim rau kev ua haujlwm. Nws cov yam ntxwv tsis siv neeg, suav nrog kev tswj qhov kub thiab txias thiab qhov ntsuas qhov ntsuas, tuaj yeem ua tau yooj yim programmed thiab saib xyuas, tso cai rau cov neeg ua haujlwm tau yooj yim saib xyuas tag nrho cov txheej txheem casting. Qhov no tsis tsuas yog txhim kho kev ua haujlwm ntawm kev ua haujlwm tab sis kuj txo qis qhov xav tau kev cob qhia dav dav, ua rau nws nkag mus rau ntau yam ntawm cov neeg siv.

4.Lub tshuab yog tsim nrog durability thiab kev ntseeg siab nyob rau hauv lub siab. Nws tau tsim nrog cov ntaub ntawv zoo thiab cov khoom siv los tiv thaiv kev ua haujlwm tsis tu ncua, ua kom muaj kev ua haujlwm ntev thiab qis qis. Qhov kev tsim kho muaj zog no ua ke nrog kev tswj xyuas nruj kom ntseeg tau tias lub tshuab kub tsis siv neeg molding muab cov txiaj ntsig zoo ib yam thiab txhim khu kev qha uas ua tau raws li qhov xav tau ntawm cov khoom ntim ntau lawm.

Nws ua haujlwm li cas:

Kev npaj ua ntej Casting:

Kub yog muab tso rau hauv ib lub graphite los yog ceramic pwm nyob rau hauv lub tshuab nqus tsev chamber.

Chamber yog kaw, thiab lub tshuab nqus tsev twj tshem tawm cov pa oxygen los tiv thaiv oxidation.

Melting & Pouring:

High-frequency induction cua sov melts kub li ntawm 10-15 feeb (4KG qauv).

Nqus pouring kom tsis txhob muaj cua npuas los yog impurities.

Txias & Demolding:

Ua-nyob rau hauv cua txias system accelerates solidification, thaum automated demolding kom bar kev ncaj ncees.

Daim ntawv thov:

1.Gold Refining: Standardized bullion ntau lawm rau tsev txhab nyiaj, mints, thiab bullion dealers.

2.Jewelry Manufacturing: Kev cai kub bar casting rau high-end hniav nyiaj hniav kub hom.

3.Kev Tshawb Fawb & Kev Kawm: Siv los ntawm cov tsev kawm ntawv qib siab thiab cov tsev kawm tshawb fawb rau kev sim thiab ua qauv qhia.

FAQ:

Q1. Dab tsi ua rau HS-GV4 zoo tagnrho rau kub / nyiaj bar ntau lawm?

A1: High Precision: 10 "PLC touchscreen (Weinview / Siemens) kom paub meej qhov kub thiab txias (txog 1,500 ° C).

Lub Sijhawm Sijhawm Sijhawm: Ncua 4kg kub (4x1kg tuav lossis 16x100g tuav) hauv 10-12 feeb.

Nqus Casting: Tshem tawm porosity rau flawless bullion zoo.

Inert Gas Protection: Siv argon/nitrogen los tiv thaiv oxidation thaum casting.

Q2. Qhov kub bar ua tshuab ua kom yooj yim rau txheej txheem casting li cas?

A2: Kev Ua Haujlwm Ib Leeg: Automates melting, pouring, thiab txias rau kev ua yuam kev-dawb ntau lawm.

Lub tshuab nqus tsev ua haujlwm siab: Ua kom lub tshuab nqus tsev zoo sib xws rau cov khoom tsis muaj qhov tsis xws luag.

PLC Tswjhwm: Kho qhov ntsuas qhov ntsuas (kub, lub sijhawm voj voog) ntawm lub vijtsam kov rau cov hlau sib txawv.

Q3. Cov hlau dab tsi tuaj yeem ua tus txheej txheem HS-GV4?

A3: Precious Hlau: Kub (24K, 22K, 18K), nyiaj (sterling, nplua).

Optional Customization: Adaptable rau platinum / palladium (hu rau specs).

Q4. HS-GV4 piv rau phau ntawv casting li cas?

A7: Kev sib raug zoo: Tshem tawm tib neeg kev ua yuam kev rau qhov hnyav hnyav / purity.

Nqi-Efficient: Tsawg nqi zog thiab cov khoom pov tseg.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115