Is it worth getting a Metal 3D printing technology powder molding process method summary?

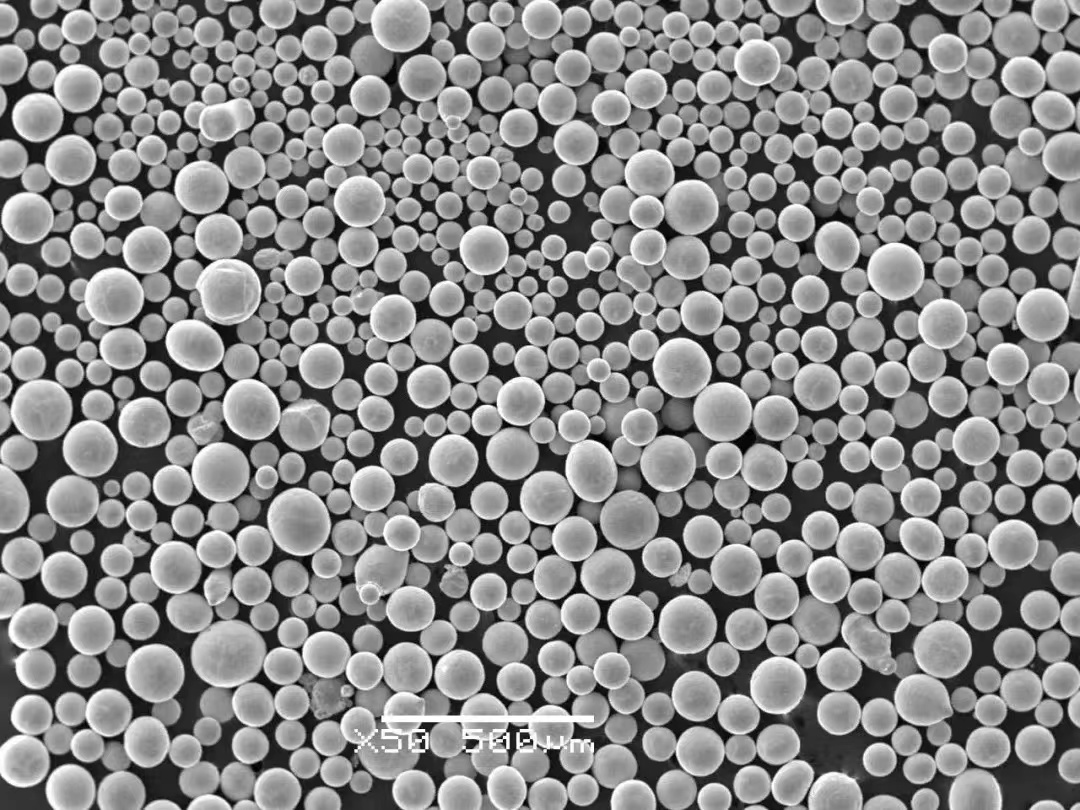

As the most important link in the industry chain of 3D printing of metal parts, 3D printing metal powder is also the biggest value. At the World 3D Printing Industry Conference 2013, leading experts in the World 3D printing industry gave a clear definition of 3d printed metal powder, that is, the size of less than 1mm of metal particles. It includes single metal powder, alloy powder and some refractory compound powder with metal property. At present, 3D printing metal powder materials include cobalt-chromium alloy, stainless steel, industrial steel, bronze alloy, titanium alloy and nickel-aluminum alloy. But the 3D printed metal powder must not only possess good plasticity, but also meet the requirements of fine particle size, narrow particle size distribution, high sphericity, good fluidity and high loose density. Prep plasma rotary electrode atomizing powder equipment PREP plasma rotary electrode atomizing powder equipment is mainly used for the production of nickel-based superalloy powder, titanium alloy powder, stainless steel powder and refractory metal powder, etc. , the prepared powder has high quality and is widely used in the fields of electron beam selective melting, laser melting deposition, spraying, thermal static pressing and so on. Working principle the metal or alloy into consumable electrode rod material, through plasma arc will be high-speed rotating electrode end melting, the centrifugal force generated by high-speed rotating electrode molten metal liquid will be thrown out to form small droplets, the droplets are cooled at high speed in the inert gas and solidify into spherical powder particles.

Process features

● high quality powder, smooth and clean surface of powder particles, very few hollow powder and satellite powder, less gas inclusions

● simple process parameters control, easy operation, automatic production

● strong applicability, refractory Ti, Ni, Co metals and alloys can be prepared

About Hasung

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115