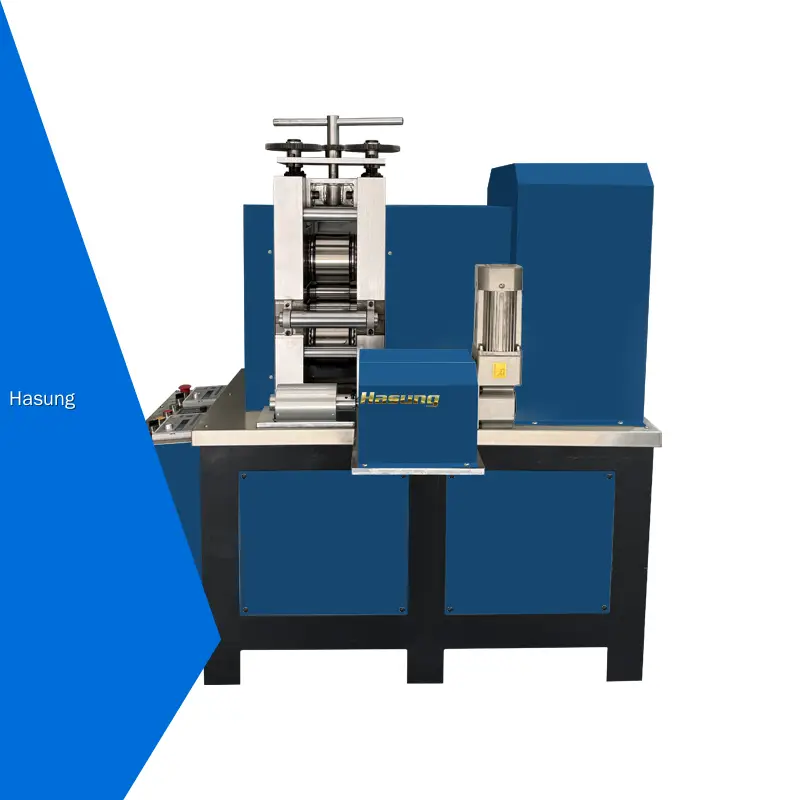

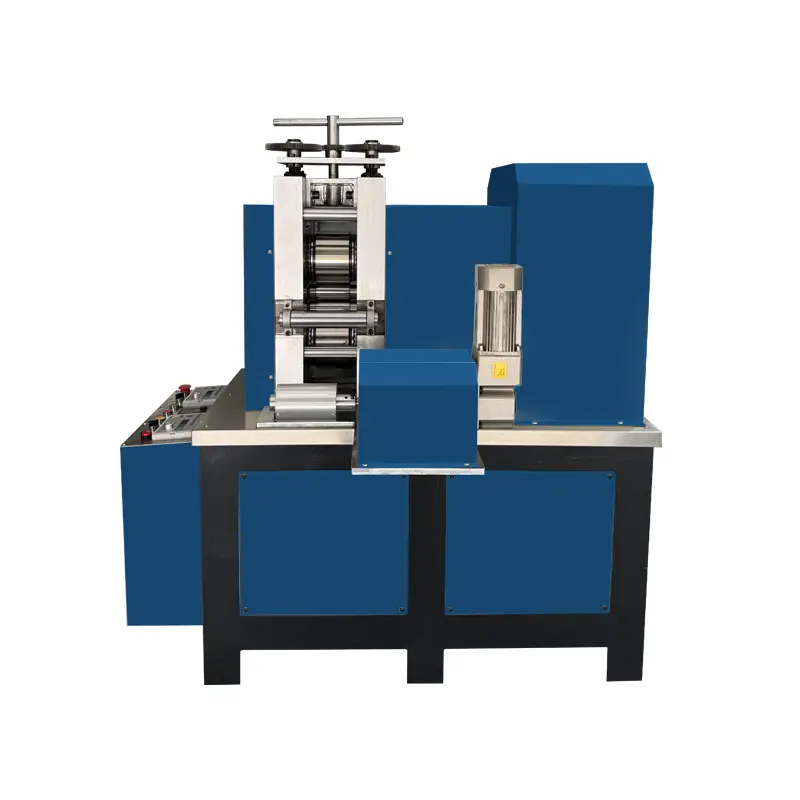

4 Shaft Goldsmith Mill with Mitsubishi PLC Touch Panel

Product advantages

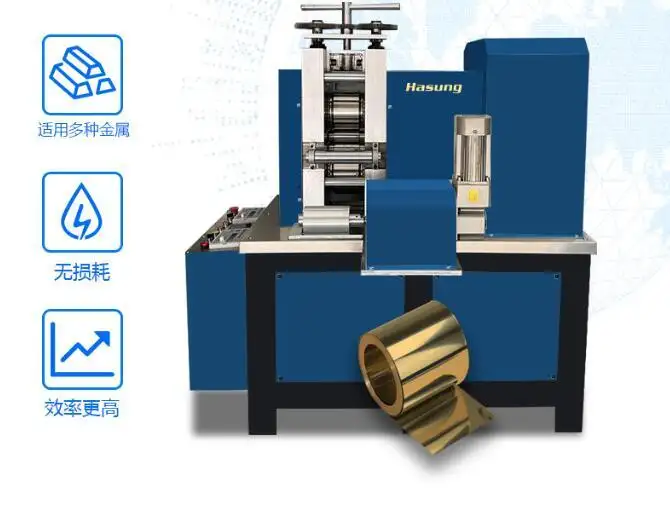

The 4 Shaft Goldsmith Mill with Mitsubishi PLC Touch Panel offers precise and efficient metal shaping for jewelry makers. With its advanced Mitsubishi PLC Touch Panel, users can easily control and program the mill for customized designs. Its four shaft design provides added stability and control, making it a valuable tool for professional goldsmiths and craftsmen.

Company profile

Our company is a leading manufacturer of precision machinery, specializing in the production of high-quality goldsmith mills. With cutting-edge technology and innovation at our core, we are proud to introduce the 4 Shaft Goldsmith Mill with Mitsubishi PLC Touch Panel. This state-of-the-art machine offers unparalleled precision and control, making it the perfect tool for intricate goldsmithing projects. Our commitment to excellence and customer satisfaction sets us apart in the industry, ensuring that our products not only meet but exceed expectations. Trust in our company for all your goldsmithing needs and experience the difference of superior quality and reliability.

Why choose us

Our company is a leading manufacturer of precision machinery, specializing in the production of high-quality goldsmith mills. Our 4 Shaft Goldsmith Mill, equipped with a Mitsubishi PLC Touch Panel, ensures efficient and precise operation for goldsmiths and jewelry makers. With a strong focus on innovation and technology, we are committed to providing our customers with cutting-edge solutions that enhance their craft. Our dedication to quality and customer satisfaction sets us apart in the industry, making us a trusted partner for all your goldsmithing needs. Experience the excellence of our products and elevate your goldsmithing experience with us.

Product Introduction

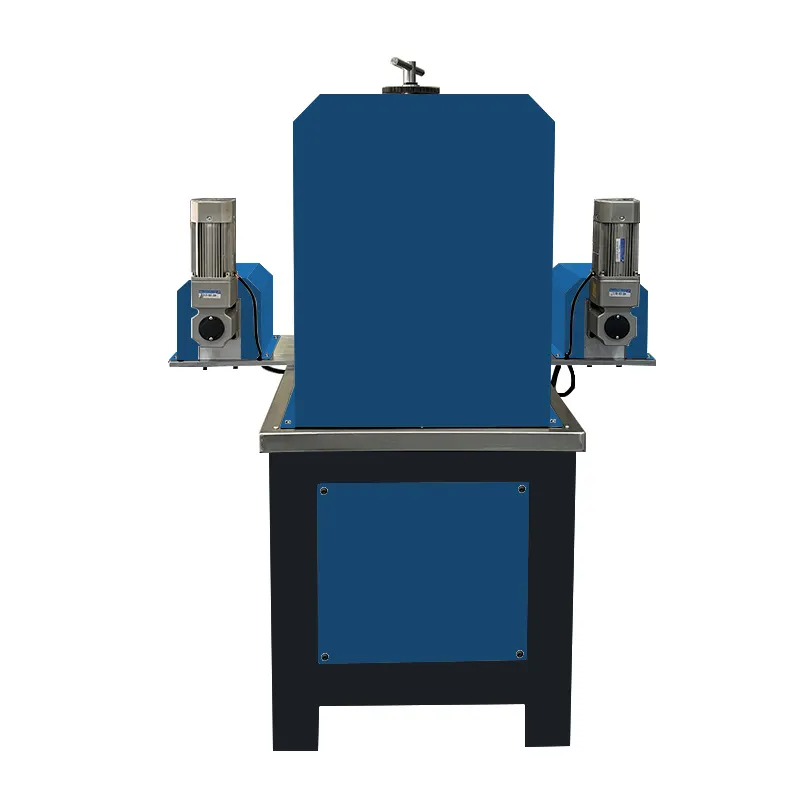

Model No. : HS-F15HP

Voltage: 380V, 3 phase, 50Hz

Motor power: 7.5KW

Motor power of shaft rise and drop: 0.75KW

Motor power of winding and unwinding: 0.75KW

Roller size: Big roller: diameter 200 × width 250mm; small roller: diameter 60 × width 250mm

Roller material: HSS

Roller Hardness: 63-67°

Dimensions: 1060* 1360*1800mm

Weight: approx. 1200kg

Controller: Siemens touch panel

Feature: equipped with Clutch with synchronous magnetic powder for front and rear winders.

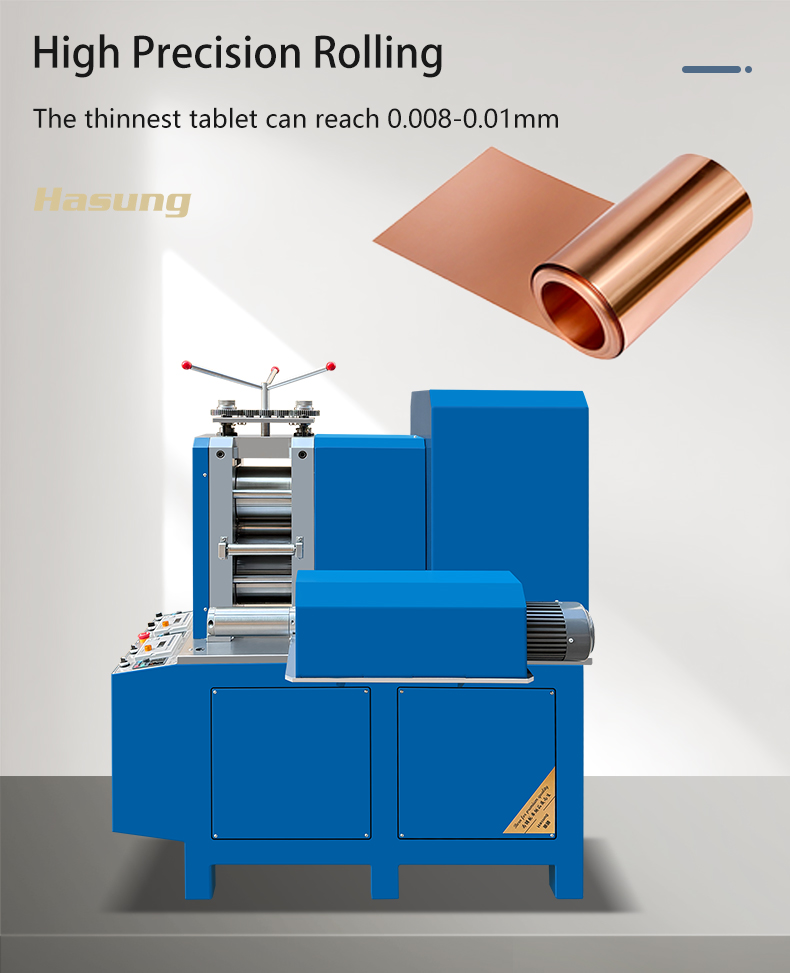

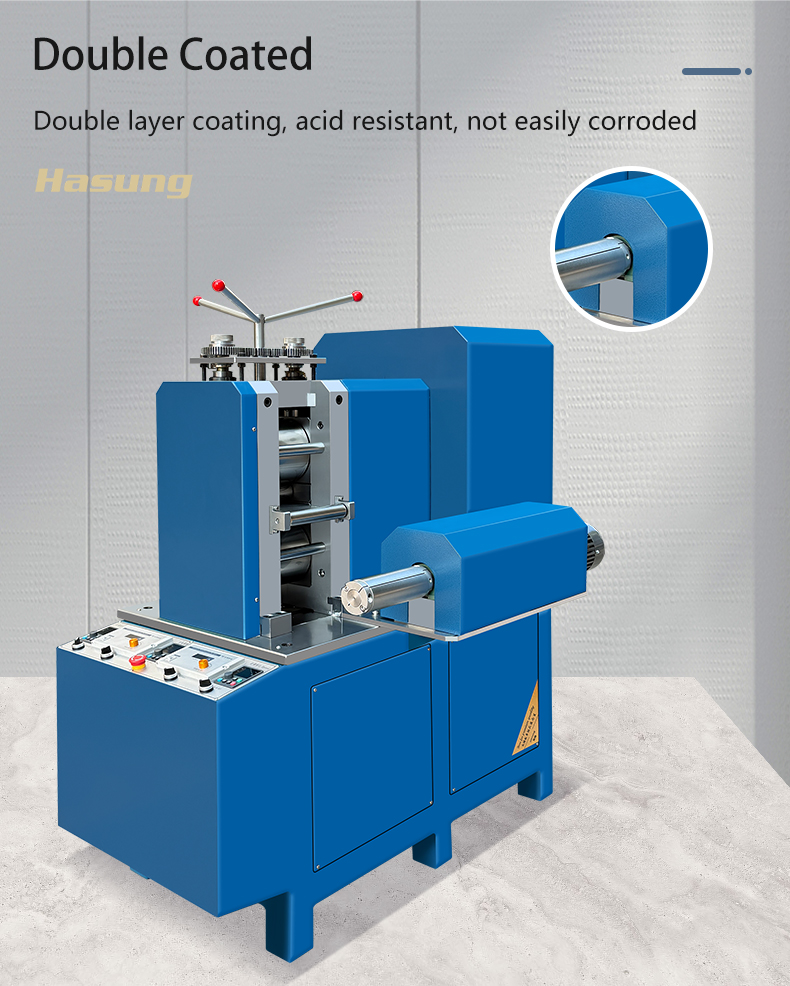

Advantage: The input thickness of the tablet is 5mm, minimum rolling sheet size for gold sheet is 0.008-0.01mm, the frame is electro-statically dusted, the body is plated with decorative hard chrome, and the stainless steel cover is beautiful and practical without rust. using Siemens PLC.

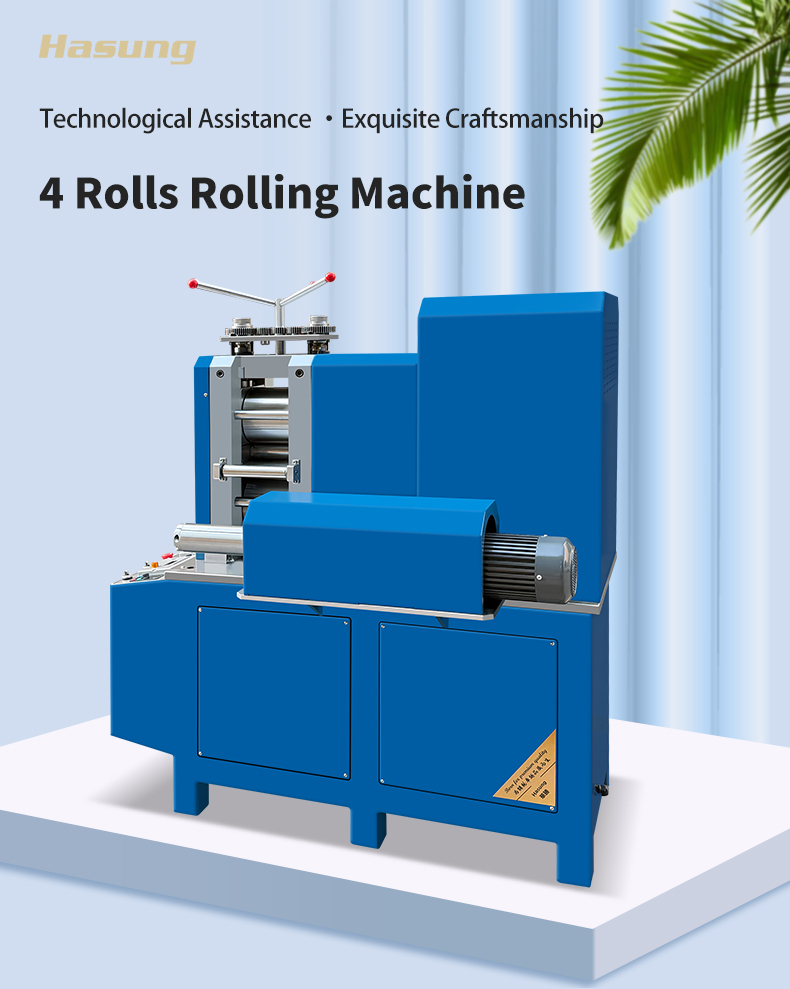

Hasung High precision 4 Rollers Gold Foil Sheet ROLLING MILL is mostly used for making gold silver copper thin sheet, for gold,

could be minimum 0.003-0.01mm, for copper, could be minimum 0.015-0.02mm.

With Siemens touch panel controller,

with Siemens PLC modular.

Clutch with synchronous magnetic powder

Roller width: 250mm,

Roller material: HSS

Company Advantages

Frequently Asked Questions about jewelry rolling machine

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115