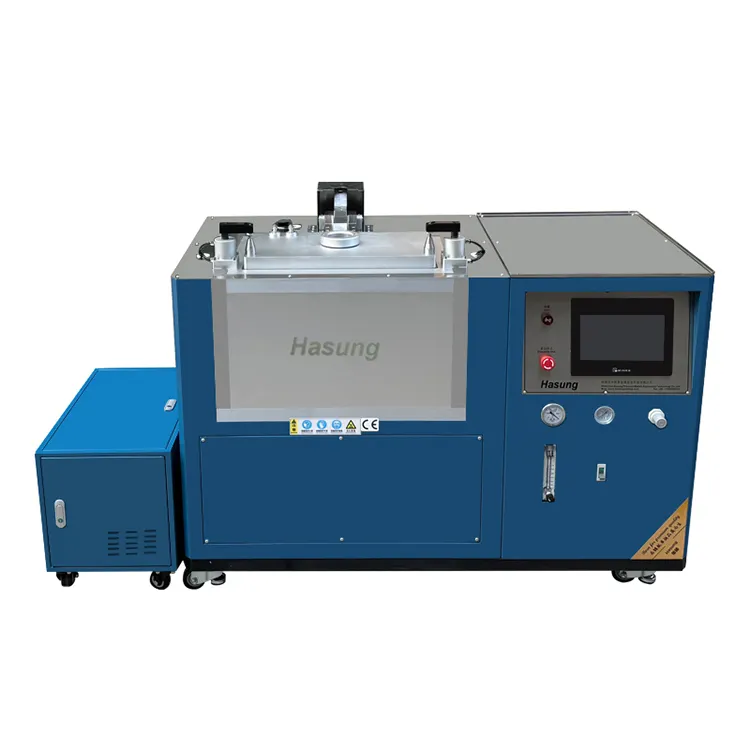

Copper Melting Machine: High-End Technology for Stable Performance

Product advantages

Our Copper Melting Machine stands out for its high-end technology, delivering stable performance with precision and efficiency. Equipped with advanced features such as temperature control and automatic shut-off, this machine ensures safe and reliable operation. Its durable construction and user-friendly design make it an indispensable tool for industrial applications.

Company profile

At our company, we pride ourselves on offering cutting-edge technology in our copper melting machines. With a focus on stability and performance, our high-end machines are designed to provide reliable and efficient melting processes. Our team of experts is dedicated to delivering top-notch quality and excellent customer service, ensuring that our customers have a seamless experience from purchase to operation. With a commitment to innovation and precision, we strive to exceed expectations and set the standard in the industry. Trust us for your copper melting needs and experience the difference that our advanced technology can make.

Enterprise core strength

At Copper Melting Machine, we take pride in offering cutting-edge technology for the most stable and reliable performance. With our high-end equipment, you can expect efficient and precise copper melting processes, enabling you to meet your production goals with ease. Our company's commitment to quality and innovation sets us apart in the industry, ensuring that you receive top-of-the-line machinery that delivers superior results every time. Trust in Copper Melting Machine to provide the tools you need for success in your metal melting operations.

In this era, it is necessary for any enterprise including Shenzhen Hasung Precious Metals Equipment Co., Ltd to improve our R&D strength and develop new products on a regular basis. The Metal Casting Machinery product will supply to all over the world, such as Europe, America, Australia,Uganda , Oman ,Sri Lanka , Surabaya . Looking back to the good old days,Shenzhen Hasung Precious Metals Equipment Co., Ltd have done our best to achieve our goal of serving customers with the best quality products and services. In the future, we will keep improving our capabilities and upgrading technologies to provide more and better products to satisfy the growing needs of customers.

| MODEL No. | HS-GV15 | HS-GV30 | HS-GV60 |

| Voltage | 380V, 50/60Hz,3phases | 380V, 50/60Hz,3phases | 380V, 50/60Hz,3phases |

| Maximum Power | 60KW | 70KW | 80KW |

| Casting Time | 15-20 minutes | 18-25 minutes | 20-30 minutes |

| Capacity | 1pcs 15kg | 1pcs 30kg gold. | 1pcs. 30kg silver |

| Application Metals | Gold,silver | ||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | ||

| control system | Siemens touch screen + Siemens PLC intelligent control system | ||

| Blanketing with inert gas | Nitrogen/argon | ||

| Cooling type water | Water chiller or Running water | ||

| Vacuum pump | High Level Vaccum pump -98Kpa | ||

| Max. Temp | 1500°C | ||

| Heating Technology | Germany IGBT Induction Heating | ||

| Dimension | 1530X800X1060mm | ||

| Weight | Approx. 500kg | ||

| Core components | Our main components are original from Japan and Germany such as Taiwan Weinview, AirTec, SMC, Siemens, Schneider, Omron, etc. | ||

| Advantage | Saving energy, fast melting, Saving inert gas 3 times than others, inert gas and vacuum automatically works, perfect casting result. Ultra-low failure rate, long lifetime using without troubles. | ||

Mechanical arm robot is available for easy take-out the heavy gold silver bars.

The Fascinating Production Process of a 30 Kilogram Gold Bar

Gold has been a symbol of wealth and luxury for centuries, and the process of producing a 30kg gold bar is even more fascinating. From mining to refining, gold's journey from the ground to shiny, valuable bullion is a complex and complex process. In this blog, we’ll explore why people produce these large gold bars, the processes involved, and the importance of these bars in the financial and luxury world.

The production of the 30kg gold bars is a result of the high demand for gold in various industries such as jewelry, electronics and investments. Gold is a precious metal that has historically been valued for its beauty and rarity. Its unique properties, such as corrosion resistance and ductility, make it an ideal material for a wide range of applications. As a result, demand for gold continues to be strong, driving the production of large gold bars to meet this demand.

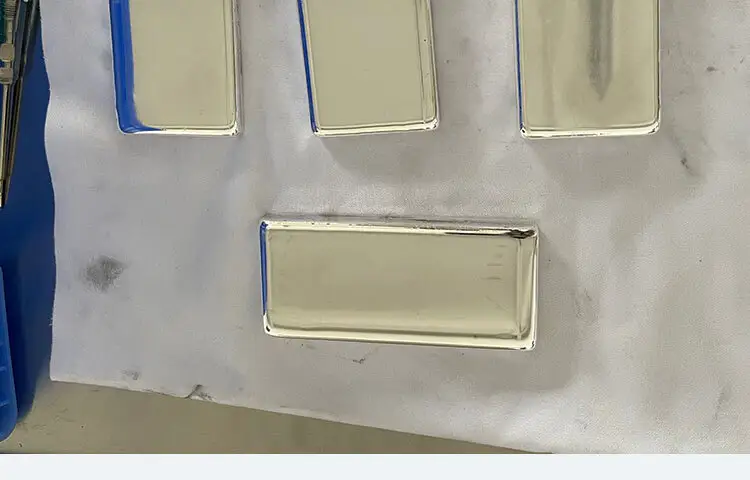

The process of producing 30kg gold bars begins with mining gold ore from the ground. Gold is usually found in underground deposits or river beds, and the mining process involves extracting the ore from these sources. Once the ore is extracted, it is transported to a refinery where pure gold is extracted from the ore through a series of processes. These processes include crushing, grinding and chemical treatments to separate the gold from other minerals and impurities.

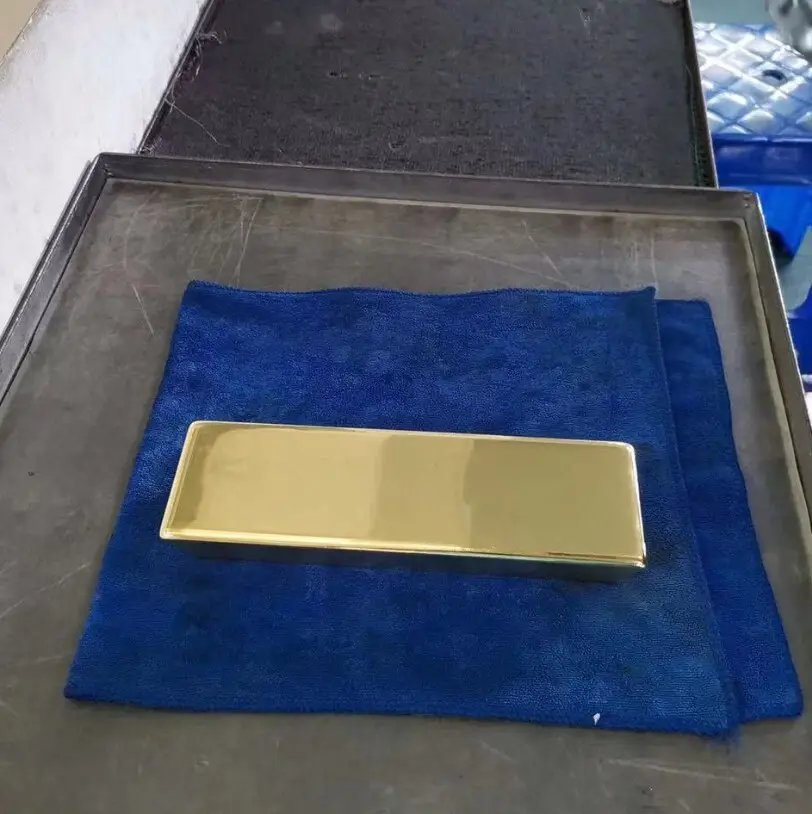

After the gold is extracted from the ore, it is melted and poured into molds to form large gold bars. 30kg gold bars are the standard size used in the gold industry and are often referred to as “good delivery” bars. These gold bars are carefully weighed and engraved with a unique serial number and gold purity (usually 99.99%). This ensures that the gold bars are of high quality and can be easily traded on the international market.

The production of 30kg gold bars is driven not only by demand for gold across various industries, but also by the investment and financial sectors. Gold has long been considered a safe-haven asset, a hedge against inflation and economic uncertainty. Large gold bars are typically held by central banks, financial institutions and high net worth individuals as a store of value and a means of portfolio diversification. The production of these gold bars plays a vital role in meeting the demand for gold as an investment asset.

In addition to its practical use in various industries and as an investment asset, the 30kg gold bar also holds an important place in the luxury and prestige world. These large gold bars are often associated with wealth and opulence and are used in the production of high-end jewelry, luxury goods, and decorative items. The sheer size and weight of these bars add to their appeal, making them coveted symbols of luxury and exclusivity.

The production of 30kg gold bars is a complex, labor-intensive process that requires skilled workers, advanced technology and strict quality control measures. Gold's entire journey from dirt to shiny, precious gold bars involves numerous steps and processes to ensure the purity and quality of the final product. The importance of these gold bars in the financial, industrial and luxury goods sectors underscores gold’s enduring appeal and value as a precious metal.

In summary, the production of 30kg gold bars is driven by high demand for gold across various industries, gold’s role as an investment asset and its importance in the world of luxury goods and prestige. The production process for these gold bars involves mining, refining and molding pure gold into standard size bars that meet the highest quality standards. Whether used in jewelry, electronics, investments, or as a symbol of wealth, the allure of the 30kg gold bar continues to attract people around the world.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115