High Vacuum Induction Melting Furnace: Efficient, Precise & Versatile

Product features

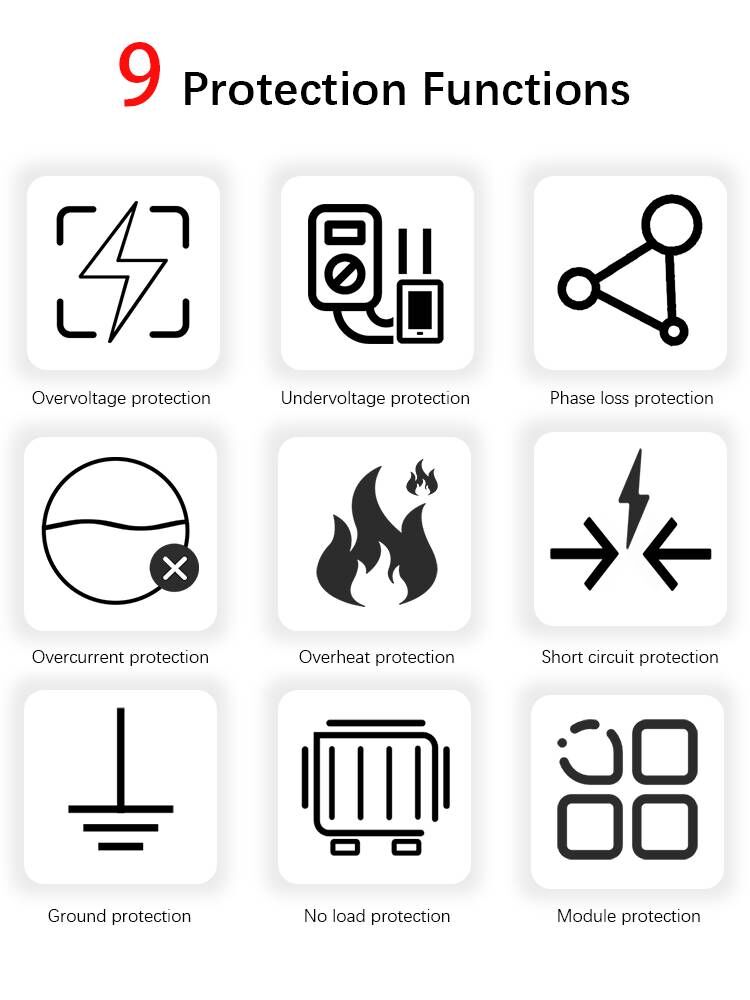

The high vacuum induction melting machine offers efficient and precise melting capabilities, ideal for various alloys such as platinum, palladium, gold, silver, and copper. With German high-frequency induction heating technology, automatic frequency tracking, and multiple protection features, the machine can melt quickly, save energy, and work efficiently. Equipped with an electromagnetic stirring function, mistake-proof automatic control system, and PID temperature control, this versatile machine ensures uniform color distribution, ease of use, and accurate temperature control for consistent and high-quality results.

Company profile

With a commitment to innovation and quality, our company specializes in the design and manufacturing of high vacuum induction melting furnaces. Our furnaces are known for their efficiency, precision, and versatility, making them ideal for a wide range of applications in industries such as aerospace, automotive, and medical. We take pride in providing our customers with cutting-edge technology that delivers exceptional performance and reliability. Our team of experts is dedicated to providing top-notch customer service and support, ensuring a seamless experience from order placement to installation and beyond. Trust us to meet your high vacuum induction melting furnace needs with excellence.

Enterprise core strength

With a reputation for excellence in designing and manufacturing high-quality industrial equipment, our company stands out as a leader in the field of high vacuum induction melting furnaces. Our expertise lies in creating efficient, precise, and versatile furnaces that meet the demanding needs of modern manufacturing processes. We prioritize innovation and attention to detail, ensuring that our products deliver exceptional performance and reliability. Customers can trust in our commitment to providing top-notch equipment that enhances productivity and delivers superior results. Choose our high vacuum induction melting furnace for a cutting-edge solution that exceeds expectations.

Since launched Precious Metals Melting Equipment, Precious metals casting machine, gold bar vacuum casting machine,gold silver granulating machine,precious metals continuous casting machine,gold silver wire drawing machine, vacuum induction melting furnace,precious has been named as one of the best and popular products in our company. Based on scientific strategic decision-making, driven by strong operating capabilities, and driven by technology and R&D capabilities, the products developed and manufactured have clear positioning and goals. Shenzhen Hasung Precious Metals Equipment Co., Ltd always stick to the core value of 'integrity and honesty' since established. We will strive forward to manufacture and provide the fine-quality products and try hard to provide the best services for our customers.

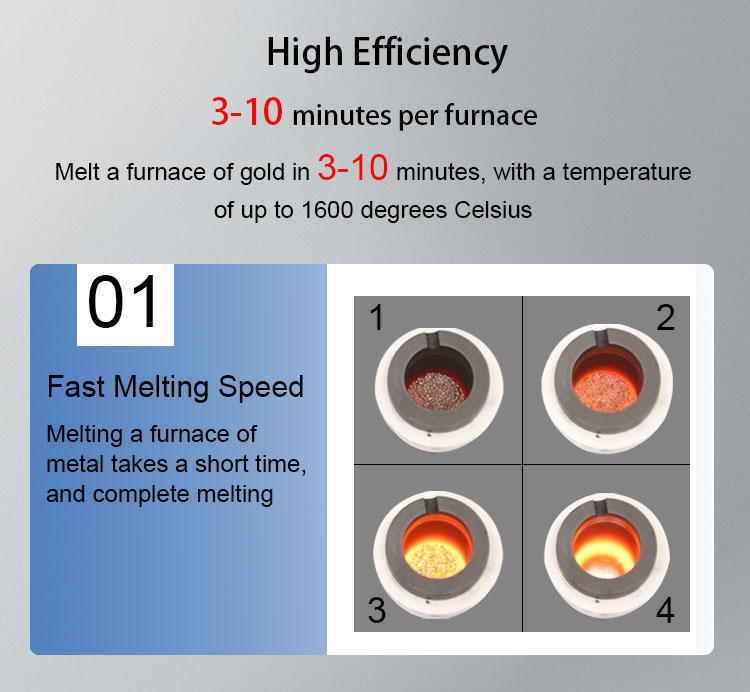

FEATURES AT A GLANCE

1.Adopt German high-frequency / Medium - frequency induction heating technology, automatic frequency tracking and multiple protection technology, which can melt in a short time, save energy and work efficiently.

2.Using electromagnetic stirring function, no segregation in color.

3.It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

4.Using PID temperature control system, the temperature is more accurate (±1°C) (optional).

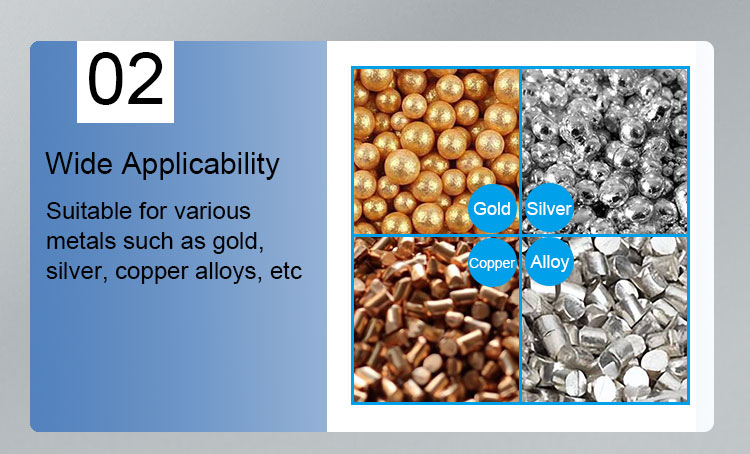

5.HS-TFQ smelting equipment is independently developed and manufactured with advanced technical level products for the smelting and casting of platinum, palladium, gold, silver, copper and other alloys.

6.This equipment uses domestic and foreign brand components.

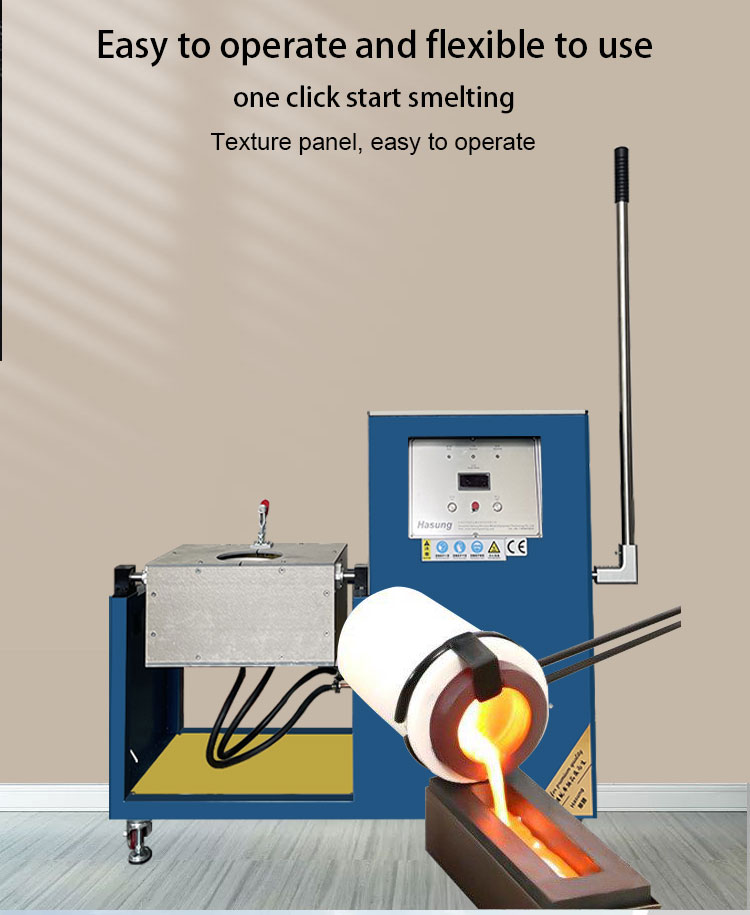

7. Safe for operator with tilting pouring at the side for the handle.

Technical specifications:

| Model No. | HS-TF10 | HS-TF15 | HS-TF20 | HS-TF30 | HS-TF50 | HS-TF60 | HS-TF100 |

| Voltage | 380V 50Hz 3 phases | ||||||

| Power | 15KW | 20KW | 30KW | 30KW | 40KW | 50KW | 60KW |

| Max Temp | 1600℃ | ||||||

| Melting speed | 3 - 6 Mins | 3 - 6 Mins | 3 - 6 Mins | 4 - 6 Mins | 6 - 10 Mins | 5 - 8 Mins | 8 - 10 Mins |

| Temp Accuracy | ±1°C (optional) | ||||||

| Temperature detector | PID Temperature Control / Infrared pyrometer (Optional), extra cost added. | ||||||

| Capacity (Gold) | 10KG | 15KG | 20KG | 30KG | 50KG | 60KG | 100KG |

| Application | Gold K-Gold Sliver Cooper and other alloys (Platinum, Palladiu, Steel, Rhodium is customzied) | ||||||

| Cooling type | Water chiller(sold separately) or Running water (water pump) | ||||||

| Dimensions | 115*49*102cm 125*65*115cm | ||||||

| Net Weight | 100kg | 110KG | 120KG | 130KG | 150KG | 160KG | 180KG |

| Shipping Weight | 180kg | 190KG | 200KG | 200KG | 215KG | 230KG | 280KG |

Products Description:

Title: Advantages of using inclined induction melting furnaces for precious metals

When melting and refining precious metals, the choice of equipment can significantly impact the efficiency and quality of the process. One of the most popular options for this purpose is the tilt-type induction melting furnace. This advanced technology offers numerous advantages for melting and refining precious metals, making it the first choice for many industries.

Efficient melting process

One of the main advantages of using tilt induction to melt precious metals is its efficient melting process. Induction heating technology heats metal quickly and evenly, resulting in faster melting times compared to traditional methods. This not only saves time but also reduces energy consumption, making the process more cost-effective.

Precise temperature control

Another advantage of tilt-type induction melting furnaces is their ability to provide precise temperature control during the melting process. This is crucial when working with precious metals, as maintaining the correct temperature is critical to achieving the desired results. The advanced control systems of these furnaces ensure that the metal is heated to the precise temperatures required for melting and refining, resulting in a high-quality product.

Clean and environmentally friendly

Inclined induction melting furnaces are known for their clean, environmentally friendly operation. Unlike traditional melting methods that rely on fossil fuels, induction heating uses electricity to generate heat, resulting in a cleaner, more sustainable process. This makes it an attractive option for companies looking to reduce their environmental impact while maintaining high production standards.

Improved security features

Safety is a top priority in any industrial process, and tilt-in induction melting furnaces are designed with advanced safety features to ensure a safe working environment. From automatic shut-off systems to protective guards, these furnaces are equipped to minimize the risk of accidents and ensure the health of operators and workers.

Versatility and flexibility

Inclined induction melting furnaces offer a high degree of versatility and flexibility, making them suitable for a variety of precious metal melting and refining applications. Whether it's gold, silver, platinum or other precious metals, these furnaces can accommodate every type of material and melting requirements. Their tilting mechanism also allows for easy pouring and transfer of molten metal, adding to overall flexibility.

Consistent and high-quality output

Consistency and quality are crucial when working with precious metals, and tilt induction melting furnaces excel at delivering consistent and high-quality output. Precise control of the melting process, coupled with the uniform heating provided by induction technology, ensures that the molten metal meets the required purity and composition standards.

Cost-effective operations

In addition to efficiency and environmental benefits, tilt-type induction melting furnaces offer cost-effective operation. Their energy-efficient design and fast melting capabilities help reduce operating costs, while the high-quality output reduces the need for rework or additional processing, ultimately saving time and resources.

In summary, the advantages of using an inclined induction melting furnace for precious metals are obvious. From efficient melting and precise temperature control to clean and environmentally friendly operation, these furnaces offer a range of benefits that make them ideal for industries involving melting and refining precious metals. With their advanced technology, safety features, versatility and cost-effective operation, tilt-in induction melting furnaces have become an indispensable tool for achieving high-quality results in the production of precious metal products.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115