Hasung - 1kg 2kg 4kg Jewellery Vacuum Pressure Casting Machine For Platinum Gold Silver

The Hasung HS-MC Series jewellery casting machine is a high quality solution designed for precision casting of platinum, gold, silver, and other precious metal alloys. Engineered with advanced tilting vacuum pressure technology, this vacuum pressure casting machine ensures flawless results for intricate jewellery designs while minimizing oxidation and material waste.

It presents different sizes can be in line with different needs of clients, such as 1kg, 2kg and 4kg etc,. Our jewellery casting machine presents different styles can be in line with different needs of clients.

Key Features & Advantages

◆High-Precision Casting: Achieves ±1°C temperature accuracy with an infrared pyrometer, ensuring consistent melting and pouring.

◆Inert Gas Protection: Uses nitrogen or argon to prevent oxidation, ideal for high-purity metals like platinum and palladium.

◆Energy-Efficient Design: High-frequency induction heating with automatic frequency tracking reduces power consumption.

◆Tilting Vacuum System: 90° tilting mechanism and dual-chamber (positive/negative pressure) design deliver smooth, defect-free casting.

◆Intelligent Controls: Features a 7" Taiwan Weinview PLC touch panel with a POKA YOKE foolproof system for error-free operation.

◆You'll get 2 years warranty from us for all our machines.

Specification

| Model No. | HS-MC1 | HS-MC2 | HS-MC4 |

| Voltage | 380V, 50/60Hz 3 phases | ||

| Power | 15KW | 30KW | |

| Capacity (Pt/Au) | 1kg | 2kg | 4kg/5kg |

| Max Temp | 2100°C | ||

| Temp Accuracy | ±1°C | ||

| Temperature detector | inflared pyrometer | ||

| Application | Platinum, Palladium, Stainless steel, Gold, silver, copper and other alloys | ||

| Max cylinder size | 5"*6" | 5"*8" | customized |

| Inert Gas | Nitrogen/Argon | ||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | ||

| Operation mode | 90 degress tilting casting | ||

| Control System | 7" Taiwan Weinview PLC touch panel | ||

| Cooling method | Running Water or Water chiller (Sold separately) | ||

| Vacuum pump | included (63M3/h) | ||

| Dimensions | 600x550x1080mm | 600x550x1080mm | 800x680x1480mm |

| Weight | 160kg | 180kg | 280kg |

Intelligent jewellery tilting induction vacuum pressure casting machine is specially designed to produce precious metals casting and melting equipment with first class quality in China.

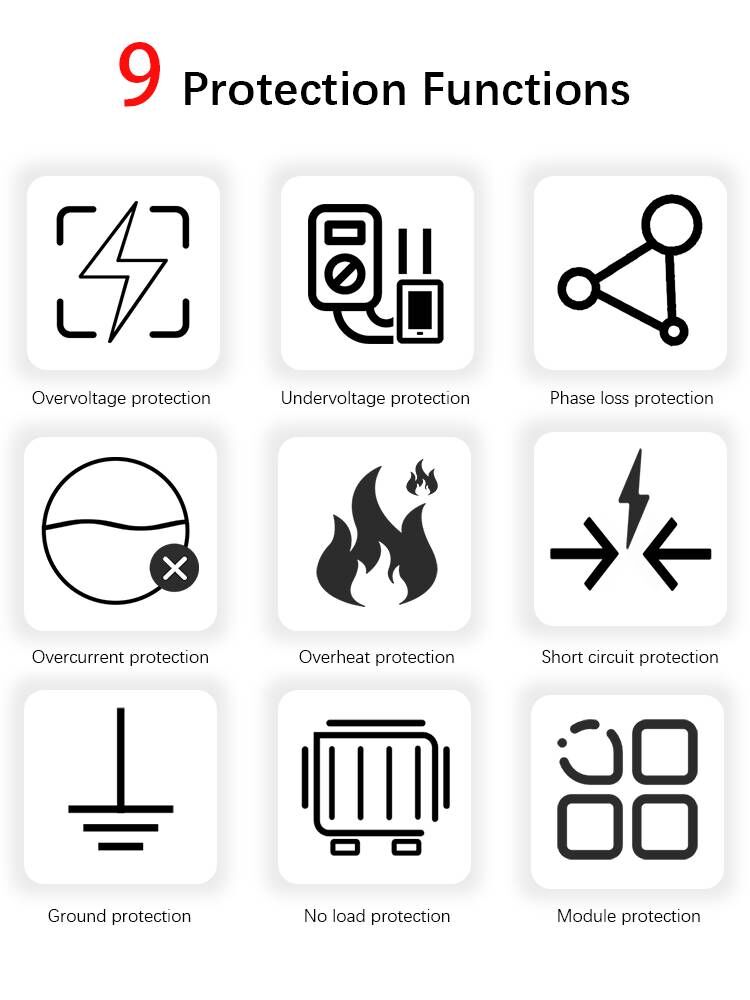

1. Using high-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving and environmental protection, and high work efficiency.

2. The closed type + vacuum/inert gas protection melting chamber can prevent the oxidation of molten raw materials and prevent the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals.

3. Using a closed + vacuum/inert gas protection melting chamber, melting and vacuuming are performed at the same time, melting chamber with positive pressure, casting chamber with negative pressure.

4. Melting in an inert gas environment, the oxidation loss of the carbon crucible is almost negligible.

5. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

7. Using infrared pyrometer temperature control system, the temperature is more accurate (±1°C).

8. The HS-MC vacuum pressurized casting equipment is independently developed and manufactured with advanced technology and is dedicated to the melting and casting of platinum, palladium, stainless steel, gold, silver, copper and other alloys.

9. This vacuum pressure jewellery casting machine uses Taiwan Weinview (optional) PLC program control system, SMC pneumatic, AirTec, and other well-known brand components at home and abroad.

How It Works

The tilting induction jewellery vacuum pressure casting equipment melts metals in an inert gas environment under vacuum, preventing impurities. Once molten, the tilting mechanism pours the metal into the mold under negative pressure, ensuring precision. The electromagnetic stirring function under inert gas protection eliminates color segregation, resulting in uniform castings.

Applications

▶Jewellery Types: Rings, necklaces, earrings, bracelets, pendants, and custom designs.

▶Materials: Platinum, palladium, gold, silver, copper, and their alloys. Whether you need platinum casting machine or gold jewellery machine

Maintenance & Care

✔Regular Cleaning: Wipe the melting chamber and crucible after use to prevent residue buildup.

✔Gas Supply Check: Ensure nitrogen/argon flow is consistent to maintain oxidation protection.

✔Temperature Verification: Periodically calibrate the infrared pyrometer for accuracy.

✔Lubrication: Grease moving parts (e.g., tilting mechanism) as recommended.

Why Choose Hasung?

With a 2-year warranty, global shipping options, and a focus on R&D, the HS-MC Series combines reliability, innovation, and efficiency. Perfect for jewellers seeking top-tier casting results.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115