Induction cua sov yog ib qho cuab yeej siv siab heev uas siv lub hauv paus ntsiab lus ntawm electromagnetic induction rau cov khoom siv hluav taws xob uas tsis muaj kev sib cuag. Cov txheej txheem cua sov no tshwj xeeb yog tsim rau kev ua cov hlau zoo xws li kub, nyiaj, platinum, palladium, thiab lwm yam, nrog rau ntau yam txheej txheem xws li melting, annealing, quenching, vuam, thiab lwm yam.

Induction cua sov tshuab thiab nws daim ntawv thov nyob rau hauv precious hlau ua

Dab tsi yog induction cua sov?

Txoj haujlwm ua haujlwm ntawm induction cua sov fais fab mov

| Hloov fais fab: | Ua ntej, hloov lub zog AC (50 / 60Hz) rau hauv DC lub zog los ntawm lub voj voog rectifier |

|---|---|

| Inverter txheej txheem: | Siv cov khoom siv hluav taws xob semiconductor (xws li IGBT, MOSFET, thiab lwm yam) los hloov DC lub zog rau hauv lub zog AC lub zog siab (ntau zaus ntau zaus ntawm 1kHz mus rau ob peb MHz) |

| Resonant sib xws: | Ua tau zoo xa cov hluav taws xob ntau zaus mus rau induction coil los ntawm LC resonant circuit |

| Electromagnetic induction: | High zaus tam sim no generates ib tug muaj zog alternating magnetic teb los ntawm ib tug induction kauj |

| Eddy tam sim no cua sov: | Cov hlau muaj txiaj ntsig muab tso rau hauv qhov chaw sib nqus ua kom muaj cov eddy tam sim no vim electromagnetic induction thiab tsim lawv tus kheej cua sov |

| Tsawg zaus (1-10kHz) | haum rau kev sib sib zog nqus nqus cua sov ntawm cov khoom loj ntawm cov khoom siv hlau zoo nkauj |

|---|---|

| Intermediate zaus (10-100kHz) | haum rau cua sov nruab nrab workpieces |

| Ntau zaus (ntau tshaj 100kHz) | siv rau saum npoo cua sov los yog zoo melting ntawm me me precious hlau |

Kev siv cov cua sov induction hauv Precious hlau ua

Siv rau melting thiab refining precious hlau xws li kub thiab nyiaj

Kev tswj qhov kub thiab txias tuaj yeem ua tiav kom txo cov hlau oxidation poob

Fais fab ntau yam: 5-50kW, zaus 10-30kHz

Cov khoom siv feem ntau siv hauv kev ua cov hniav nyiaj hniav kub

Ceev ceev me me ntawm cov hlau muaj nuj nqis (feem ntau ntau grams mus rau ob peb puas grams)

Kev khiav hauj lwm zaus yog feem ntau ntawm 50-200kHz

Xws li annealing, quenching thiab lwm yam txheej txheem

Siv los txhim kho cov khoom siv kho tshuab thiab ua haujlwm ntev ntawm cov khoom siv hlau zoo

Qhov zoo ntawm induction cua sov fais fab mov

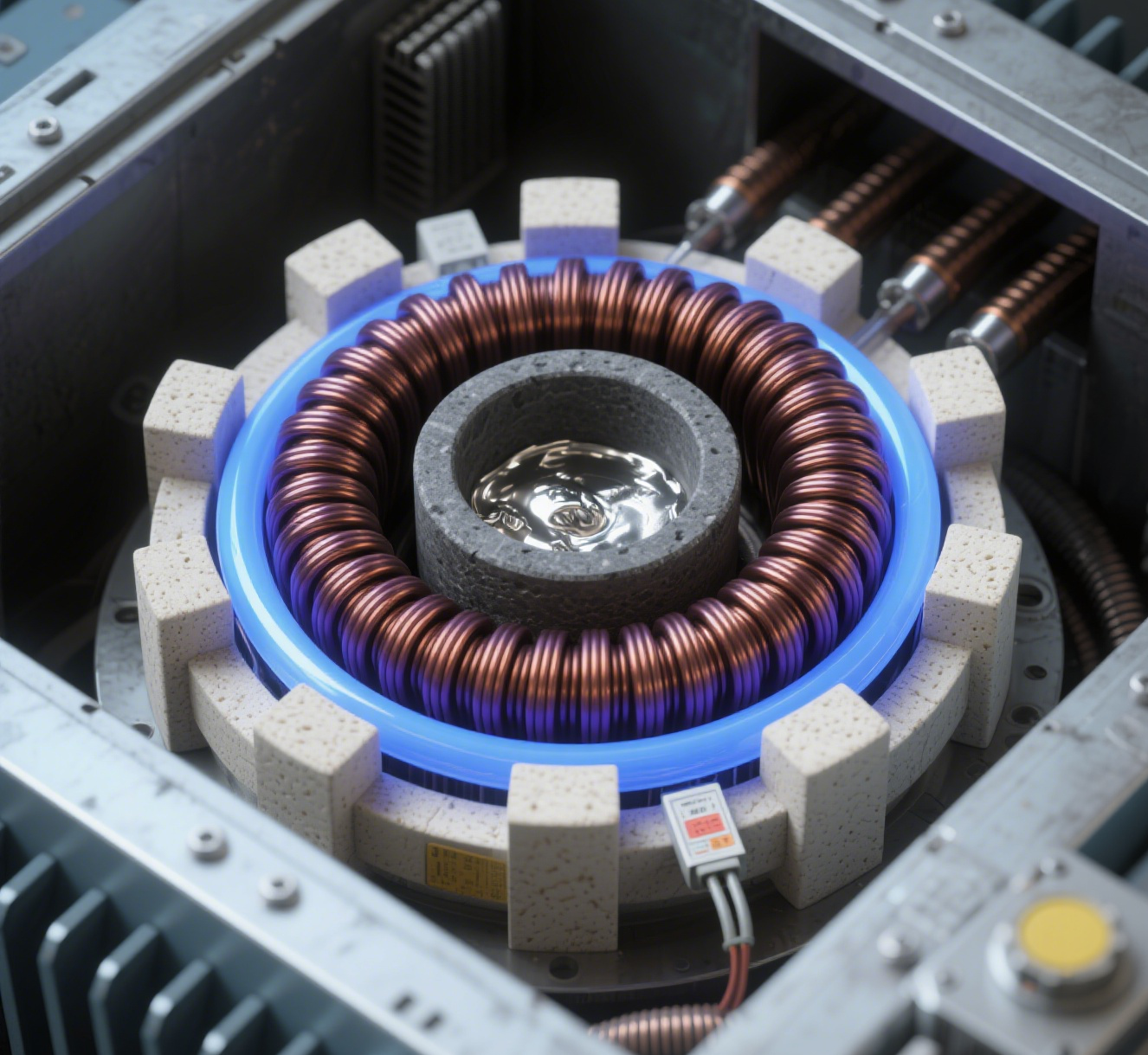

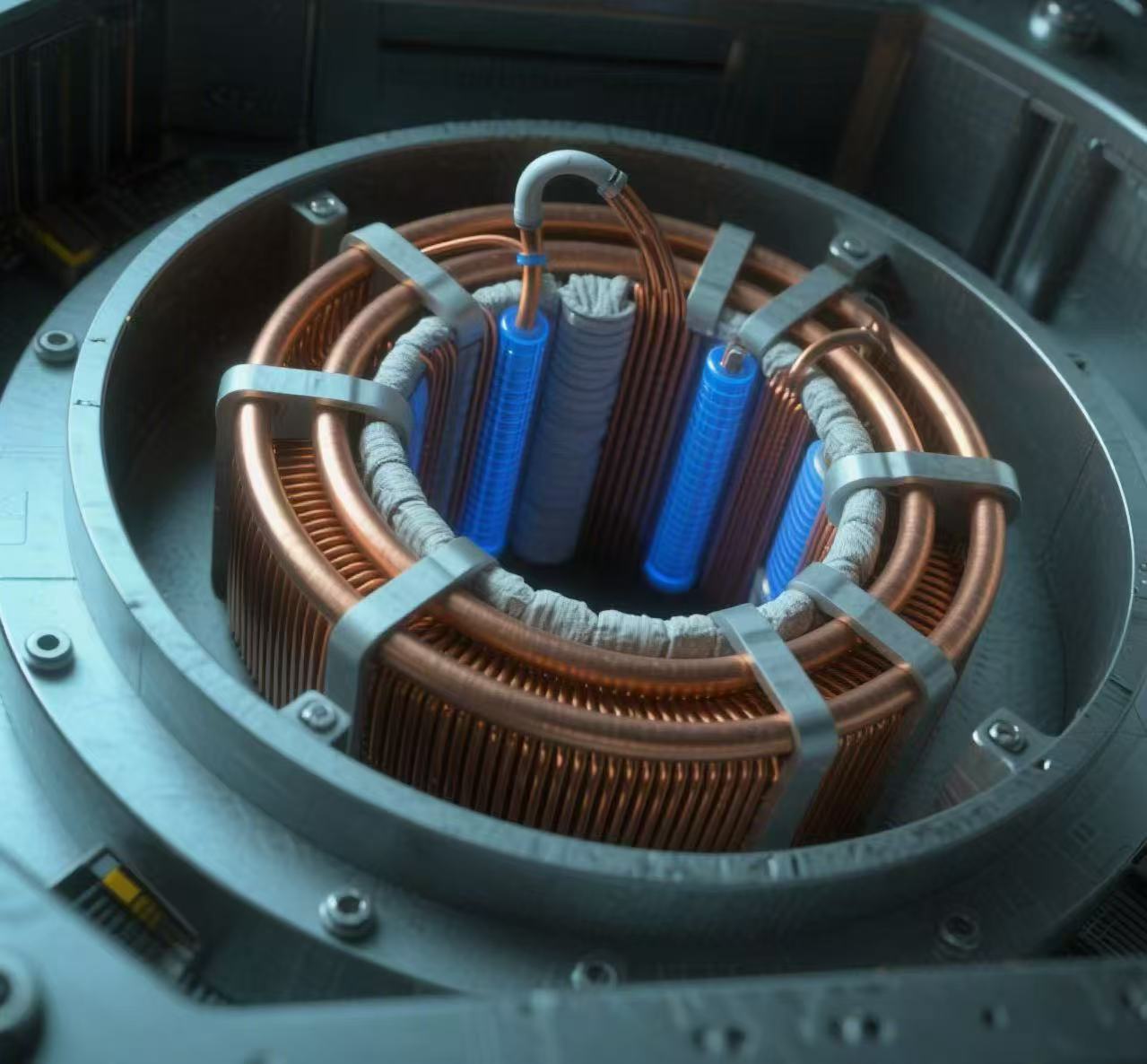

Ib qho ua tiav precious hlau induction cua sov feem ntau suav nrog:

Lub induction cua sov fais fab hloov pauv cov hluav taws xob AC zoo tib yam rau hauv lub zog hluav taws xob ntau zaus los ntawm cov txheej txheem ntawm kev hloov kho → inversion → resonance → electromagnetic induction , ua rau cov hlau muaj txiaj ntsig los ua kom sov ntawm lawv tus kheej. Nws cov tub ntxhais nyob rau hauv high-frequency inverter technology thiab harmonious vibration matching, ua ke nrog kev txawj ntse tswj, kom ua tau zoo thiab meej cua sov, lug siv nyob rau hauv lub melting, casting, thiab tshav kub kev kho mob ntawm precious hlau xws li kub thiab nyiaj.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115