Induction heating is an advanced technology that utilizes the principle of electromagnetic induction to heat conductive materials in a non-contact manner. This heating method is particularly suitable for processing precious metals such as gold, silver, platinum, palladium, etc., including various processes such as melting, annealing, quenching, welding, etc.

Induction heating technology and its application in precious metal processing

What is induction heating?

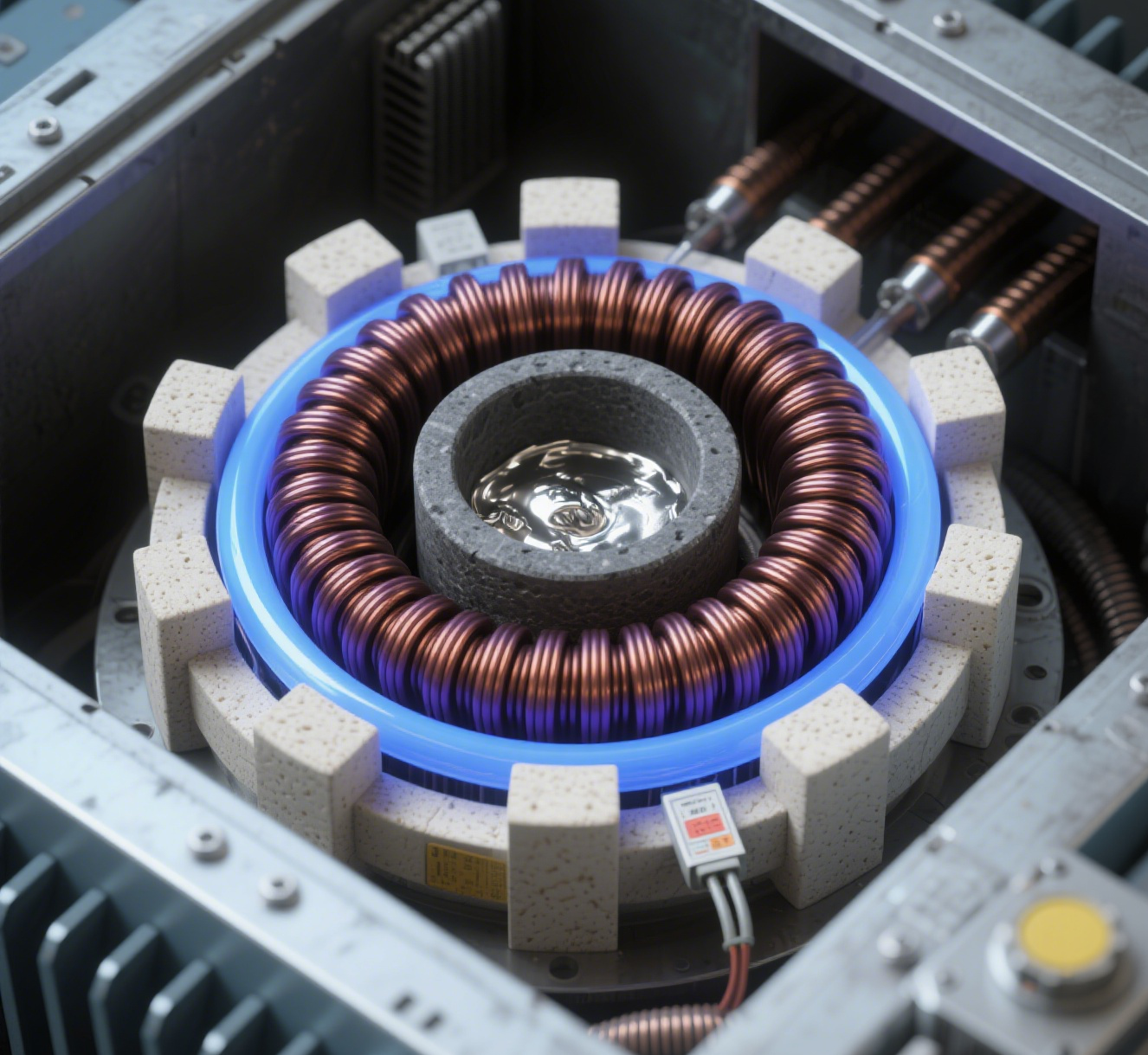

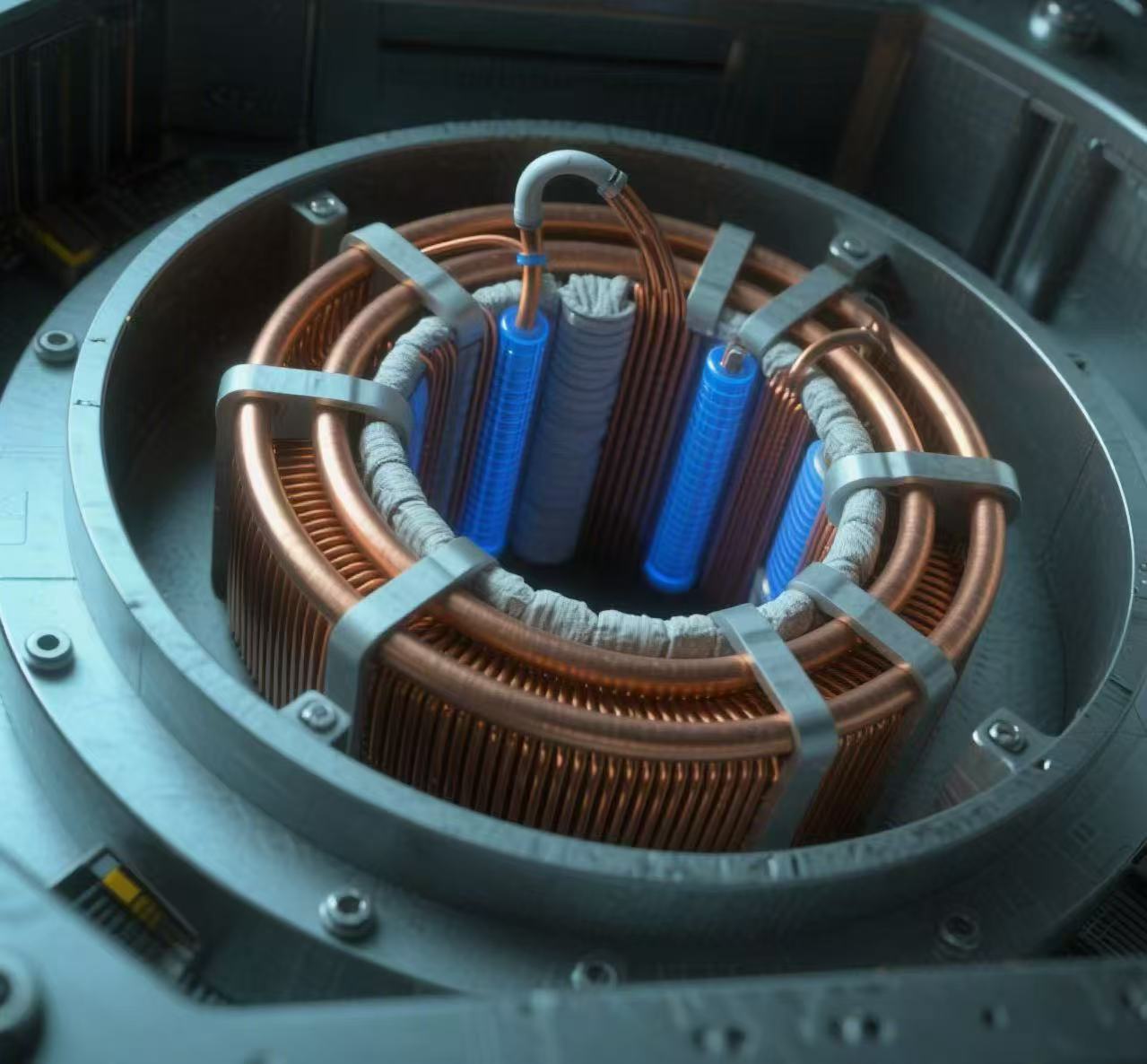

Working principle of induction heating power supply

| Power conversion: | First, convert the AC power (50/60Hz) into DC power through a rectifier circuit |

|---|---|

| Inverter process: | Use power semiconductor devices (such as IGBT, MOSFET, etc.) to invert DC power into high-frequency AC power (frequency range usually ranging from 1kHz to several MHz) |

| Resonant matching: | Efficiently transmit high-frequency electrical energy to the induction coil through LC resonant circuit |

| Electromagnetic induction: | High frequency current generates a strong alternating magnetic field through an induction coil |

| Eddy current heating: | Precious metals placed in a magnetic field generate eddy currents due to electromagnetic induction and generate their own heat |

| Lower frequency (1-10kHz) | suitable for deep penetration heating of large volume precious metal materials |

|---|---|

| Intermediate frequency (10-100kHz) | suitable for heating medium-sized workpieces |

| High frequency (above 100kHz) | used for surface heating or fine melting of small precious metals |

Typical Application of Induction Heating in Precious Metal Processing

Used for melting and refining precious metals such as gold and silver

Accurate temperature control can be achieved to reduce metal oxidation losses

Typical power range: 5-50kW, frequency 10-30kHz

Equipment commonly used in jewelry processing

Quickly melt small amounts of precious metals (usually several grams to several hundred grams)

The operating frequency is usually between 50-200kHz

Including annealing, quenching and other processes

Used to improve the mechanical properties and durability of precious metal products

Advantages of Induction Heating Power Supply

A complete precious metal induction heating system typically includes:

The induction heating power supply converts ordinary AC electricity into high-frequency electrical energy through the process of rectification → inversion → resonance → electromagnetic induction, causing precious metals to generate heat on their own. Its core lies in high-frequency inverter technology and harmonious vibration matching, combined with intelligent control, to achieve efficient and precise heating, widely used in the melting, casting, and heat treatment of precious metals such as gold and silver.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115