Lub hom phiaj ntawm dov zeb siv rau hauv cov hniav nyiaj hniav kub ua tshuab yog dab tsi?

Nkag siab lub tshuab dov

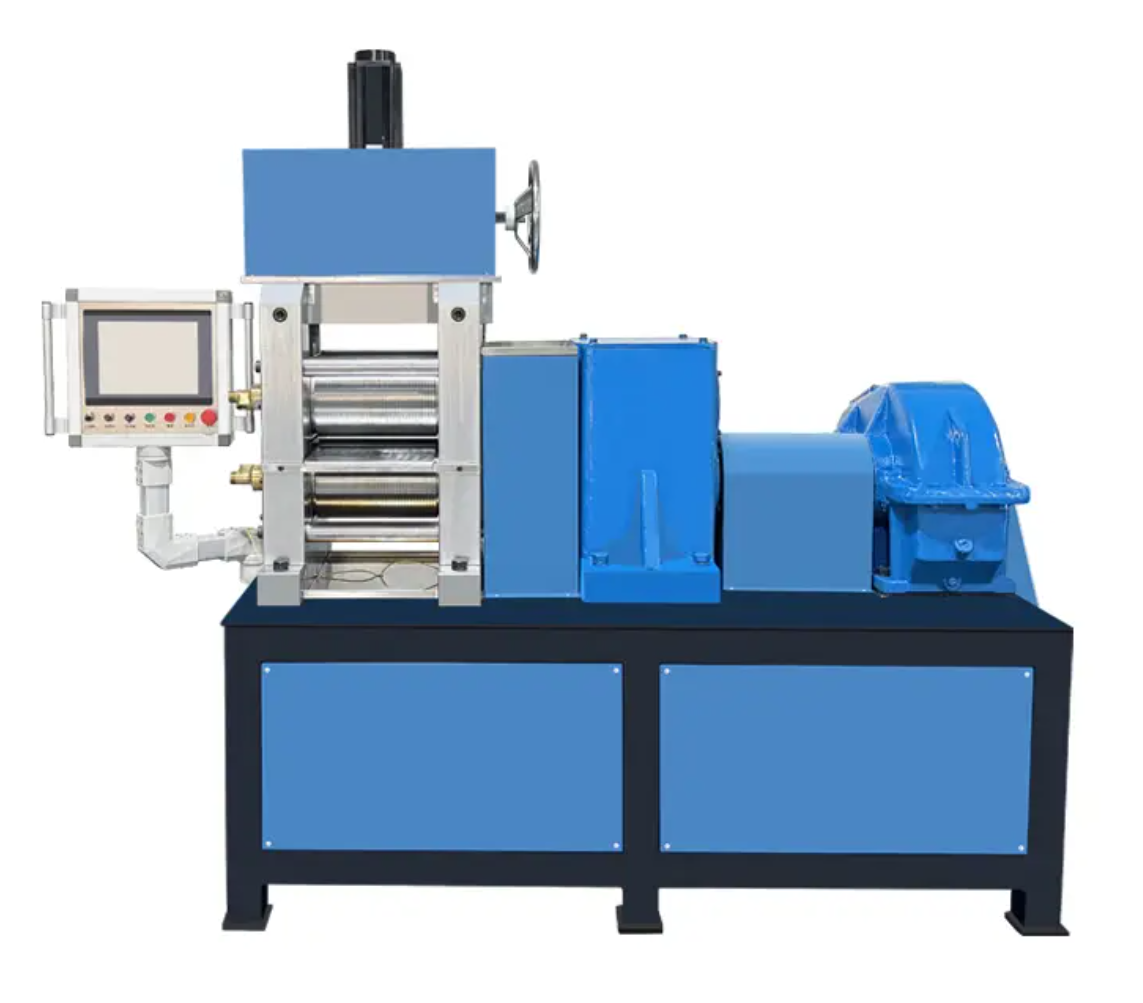

Rolling mills yog ib lub tshuab uas txo cov thickness ntawm cov hlau phaj los yog hlau los ntawm cov txheej txheem dov. Cov txheej txheem cuam tshuam nrog kev hla cov hlau ntawm ob lossis ntau dua rollers, uas siv lub siab thiab compression cov khoom. Hauv kev tsim cov hniav nyiaj hniav kub, dov mills yog tsim tshwj xeeb los ua cov hlau zoo xws li kub, nyiaj, thiab platinum, tso cai rau cov jewelers ua cov ntaub ntawv no nrog qhov tseeb.

Hom dov zeb

Muaj ntau ntau hom dov mills siv nyob rau hauv kev tsim cov hniav nyiaj hniav kub, txhua tus ua haujlwm sib txawv:

Tes Rolling Mills: Cov no yog cov ua haujlwm ntawm tes thiab zoo tagnrho rau kev ua haujlwm me me lossis hobbyists. Lawv feem ntau pheej yig dua thiab tso cai rau kev tswj ntau dua ntawm cov txheej txheem dov.

Hluav taws xob Rolling Mill: Cov tshuab no yog siv los ntawm hluav taws xob thiab tuaj yeem tuav cov khoom loj ntawm cov hlau. Lawv tsim nyog rau cov kws tshaj lij jewelers uas xav tau kev ua haujlwm zoo thiab sib xws.

Kev sib xyaw Rolling Mill: Cov no yog cov tshuab ntau yam uas tuaj yeem ua tau ntau yam haujlwm xws li dov, flattening thiab texturing. Lawv feem ntau tuaj nrog cov menyuam sib hloov tau kom haum rau ntau yam haujlwm.

Lub luag haujlwm ntawm dov zeb hauv cov hniav nyiaj hniav kub kub ntau lawm

Lub tshuab dov ua haujlwm ntau lub luag haujlwm tseem ceeb hauv cov txheej txheem ua cov hniav nyiaj hniav kub, txhua qhov ua rau tag nrho cov khoom zoo thiab tsim cov khoom kawg.

1. Txo cov tuab

Ib qho ntawm cov haujlwm tseem ceeb ntawm lub tshuab dov yog txo cov thickness ntawm cov ntawv kub los yog hlau. Los ntawm kev hla cov hlau los ntawm cov chais, jewelers tuaj yeem ua tiav cov tuab uas xav tau rau lawv cov haujlwm. Qhov no yog qhov tseem ceeb tshwj xeeb tshaj yog thaum tsim cov qauv tsim uas yuav tsum tau muaj qhov tshwj xeeb. Lub peev xwm los tswj cov tuab ua kom tsim tau yooj yim thiab ua kom cov khoom kawg ua tau raws li tus neeg siv khoom tshwj xeeb.

2. Shaping thiab shaping

Rolling mills kuj tseem siv los ua cov kub thiab ua rau ntau yam duab. Cov hniav nyiaj hniav kub tuaj yeem tsim cov ntawv tiaj tus, cov xov hlau, thiab txawm tias cov duab nyuaj los ntawm kev kho qhov chaw ntawm cov chais. Qhov no versatility yog qhov tseem ceeb rau kev tsim cov khoom sib txawv ntawm cov hniav nyiaj hniav kub xws li rings, bracelets thiab pendants. Lub peev xwm los ua kom zoo zoo kub yog qhov tseem ceeb kom ua tiav qhov xav tau zoo nkauj thiab ua haujlwm zoo hauv qhov kawg.

3. Kev ntxhib los mos thiab cov qauv

Lwm qhov tseem ceeb ntawm lub zeb yog qhov muaj peev xwm ntxiv kev ntxhib los mos thiab qauv rau kub. Muaj ntau lub rolling mills yog nruab nrog cov qauv rolls uas imprint ib tug qauv rau hauv cov hlau raws li nws yog dov. Qhov no feature enables jewelers los tsim tshwj xeeb textures thiab finishes uas txhim khu kev pom zoo ntawm lawv tej daim. Textured kub hniav nyiaj hniav kub yog feem ntau nrhiav tom qab vim hais tias lawv ntxiv qhov tob thiab tus cwj pwm rau cov hniav nyiaj hniav kub.

4. Ua hauj lwm hardening

Thaum kub dov thiab ua haujlwm, nws dhau los ua tus txheej txheem hu ua work hardening. Qhov tshwm sim no tshwm sim thaum hlau deforms, ua rau nws cov qauv sab hauv hloov thiab ua kom muaj zog. Lub tshuab dov ua kom yooj yim rau cov txheej txheem no, tso cai rau cov jewelers los tsim cov khoom thaum lub sijhawm ua kom nws lub zog. Ua hauj lwm-hardened kub yog tsawg dua yuav khoov lossis tawg, ua rau nws zoo tagnrho rau cov hniav nyiaj hniav kub uas feem ntau hnav.

5. Npaj rau kev ua haujlwm ntxiv

Lub tshuab dov kuj tseem ua lub luag haujlwm tseem ceeb hauv kev npaj cov kub rau kev ua haujlwm ntxiv. Tom qab pib dov, cov hlau tuaj yeem raug muab tshem tawm (rhuab thiab txias) kom txo tau kev ntxhov siab thiab ua rau nws muaj zog dua. Cov txheej txheem no yog ib qho tseem ceeb rau cov jewelers uas npaj yuav solder, engraving, los yog lwm yam ntxiv manipulate kub. Los ntawm kev siv lub tshuab dov kom ua tiav qhov xav tau tuab thiab cov duab, lub jeweler teeb tsa theem rau kev ua haujlwm tiav tom qab.

6. Tsim kom muaj qhov sib xws

Kev sib raug zoo yog qhov tseem ceeb hauv kev tsim cov hniav nyiaj hniav kub, tshwj xeeb tshaj yog cov khoom loj. Rolling mills ua rau cov jewelers tsim cov ntawv sib xws thiab xaim, kom ntseeg tau tias txhua daim ntawm cov hniav nyiaj hniav kub ua tau raws li cov qauv qub. Qhov kev sib xws no yog qhov tseem ceeb rau kev tswj xyuas qhov zoo thiab ua kom cov khoom sib haum nrog seamlessly, tshwj xeeb tshaj yog nyob rau hauv cov qauv tsim uas xav tau ntau yam khoom.

Cov txiaj ntsig ntawm kev siv dov mills hauv kev tsim cov hniav nyiaj hniav kub

Kev siv cov dov zeb hauv cov hniav nyiaj hniav kub kub ua tshuab muaj ntau yam zoo uas txhim khu kev tsim cov hniav nyiaj hniav kub tag nrho.

1. Txhim kho efficiency

Lub tshuab dov ua kom yooj yim cov txheej txheem ntawm shaping thiab refining kub, cia jewelers ua hauj lwm zoo. Los ntawm kev txo lub sij hawm siv shaping thiab shaping ntawm tes, jewelers tuaj yeem tsom mus rau lwm yam ntawm cov khoom siv tes ua, xws li kev tsim thiab kev ua tiav.

2. Tus nqi zoo

Kev nqis peev nyob rau hauv ib lub tshuab dov yog tus nqi zoo nyob rau lub sijhawm ntev. Los ntawm kev tsim lawv tus kheej daim ntawv thiab xaim, jewelers tuaj yeem txo cov khoom pov tseg thiab txuag nyiaj ntawm kev yuav khoom prefabricated. Tsis tas li ntawd, kev muaj peev xwm los tsim cov duab kev cai thiab qhov ntau thiab tsawg tuaj yeem ua rau muaj kev tsim kho tshiab, muaj peev xwm nce kev muag khoom.

3. Txhim khu kev muaj tswv yim

Lub versatility ntawm lub zeb tso cai rau cov jewelers sim nrog sib txawv duab, textures thiab finishes. Qhov kev ywj pheej muaj tswv yim no tso cai rau cov neeg txawj ntse thawb cov ciam teb ntawm lawv cov khoom siv tes ua thiab tsim cov khoom tshwj xeeb uas sawv tawm hauv kev ua lag luam.

4. Txhim kho qhov zoo

Lub precision muab los ntawm dov zeb pab txhim kho tag nrho qhov zoo ntawm cov hniav nyiaj hniav kub. Los ntawm kev ua tiav cov tuab thiab cov duab zoo ib yam, cov jewelers tuaj yeem xyuas kom meej tias lawv cov khoom tsis yog tsuas yog pom kev txaus siab, tab sis kuj muaj suab nrov.

nyob rau hauv xaus

Rolling mills yog ib qho cuab yeej tseem ceeb hauv kev tsim cov hniav nyiaj hniav kub, tshwj xeeb tshaj yog hauv kev ua kub. Nws lub peev xwm, los ntawm kev txo cov thickness thiab shaping mus rau texturing thiab ua hauj lwm hardening, yog ib qho tseem ceeb rau tsim high-zoo, intricate designs. Los ntawm kev nqis peev hauv lub tshuab dov rau cov hniav nyiaj hniav kub ua tshuab, craftsmen tuaj yeem ua rau lawv cov kev ua tau zoo, muaj tswv yim, thiab kev ua haujlwm zoo tag nrho. Raws li kev lag luam hniav nyiaj hniav kub txuas ntxiv mus, lub zeb tseem yog lub hauv paus ntawm kev ua haujlwm zoo nkauj, tso cai rau cov jewelers coj lawv cov duab kos duab rau lub neej.

Koj tuaj yeem tiv tauj peb los ntawm txoj kev hauv qab no:

Whatsapp: 008617898439424

Email:sales@hasungmachinery.com

Lub Vev Xaib: www.hasungmachinery.com www.hasungcasting.com

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115