How to choose a jewelry casting machine that suits oneself?

How to choose a jewelry casting machine that suits oneself?

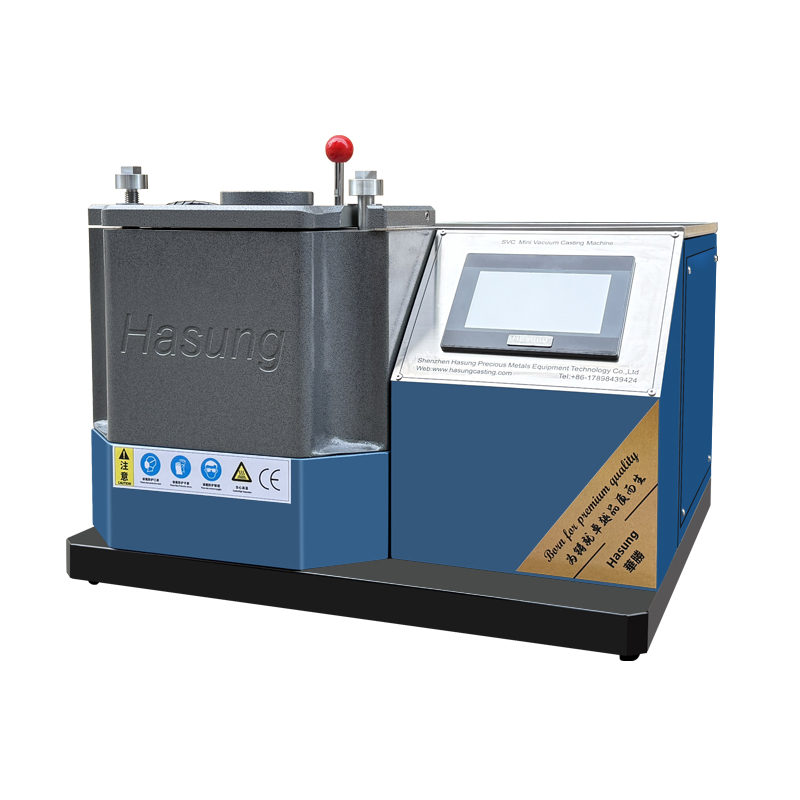

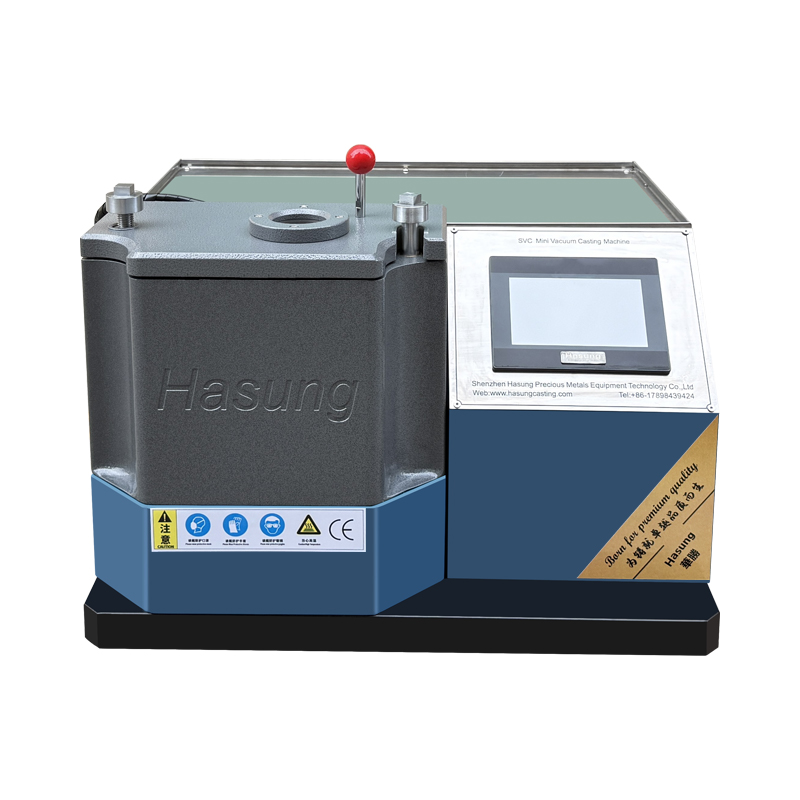

In the jewelry manufacturing industry, the jewelry casting machine is one of the crucial equipment, which directly affects the quality and production efficiency of products. How to choose a jewelry casting machine that suits oneself when facing numerous brands and models in the market? As a professional equipment supplier in the industry, Hasung Precious Metal Equipment Technology Co., Ltd. in Shenzhen provides the following suggestions to help you make a wise choice.

Before choosing a jewelry casting machine, it is important to first clarify your production needs:

>Casting type: Do you need to make fine gold or platinum jewelry, or are you mainly used for silver or alloy casting? Different metals have different requirements for equipment.

>Production scale: Is it small-scale customized production or large-scale industrial production? Different production demands correspond to different models of machines, such as manual casting machines suitable for small workshops, while fully automatic casting machines are more suitable for large factories.

Understand the basic types of jewelry casting machines:

Hasung Company provides various types of jewelry casting machines, mainly including:

HS-TVC fully automatic vacuum die-casting machine:

the preferred choice for high-precision production with full automation, suitable for large-scale high-quality demand.

HS-VPC Jewelry Casting Machine:

An economical and durable entry-level model suitable for enterprises with limited budgets. The professional choice for vacuum protection, suitable for high-purity precious metal casting.

HS-VCT vacuum die-casting machine:

a flexible and energy-saving dual-mode model that balances diverse processes and cost control, suitable for casting large-sized 3D printed wax parts.

HS-T2 Jewelry Casting Machine:

The preferred choice for fully automatic intelligent precision casting machines, the entire casting process can be completed by pressing the button twice. After inputting and storing the data as a recipe, beginners can create exquisite jewelry.

Compact and portable, suitable for small and micro scenes or educational purposes.

Centrifugal technology ensures detailed restoration, suitable for efficient production of platinum and high-temperature metals with complex designs.

>Casting accuracy

The precision of the jewelry casting machine directly affects the detailed performance of the product. High precision equipment can ensure the perfect presentation of complex patterns and small structures. The casting machine of Huasheng Precious Metal Equipment Technology adopts advanced vacuum pressure casting technology to ensure that the metal liquid fully fills the mold, reducing bubbles and sand holes.

> Heating method and temperature control

High frequency induction heating vs. resistance heating: High frequency heating has fast heating speed and high efficiency, suitable for high melting point metals; Resistance heating is more stable and suitable for fine casting.

Temperature control system: An excellent temperature control system can ensure uniform melting of metal, avoiding casting defects caused by overheating or insufficient temperature.

>Degree of automation

Manual operation: suitable for small-scale production, with low cost but limited efficiency.

Semi automatic/fully automatic: suitable for medium to large-scale production, reducing manual intervention, improving yield and production efficiency.

Jewelry casting machines require long-term stable operation, so the material and structural design of the equipment are crucial:

|| High temperature resistant materials: Key components such as crucibles and heating coils should be made of high-purity graphite or ceramic materials to ensure that they are not easily damaged during long-term use.

|| Cooling system: A good cooling system can extend the lifespan of equipment and avoid malfunctions caused by overheating.

|| The casting machine of Huasheng Precious Metal Equipment Technology adopts high-quality materials and precision manufacturing processes to ensure that the equipment can maintain stable performance even under long-term high-intensity work.

Choosing a supplier with good after-sales service is crucial, especially for high-precision equipment:

\\Technical support: Do you provide installation, debugging, and operation training?

\\Maintenance: Is there a complete after-sales team and spare parts supply?

\\Customer reputation: View reviews from other users to understand the actual user experience of the device.

Hasung Precious Metal Equipment Technology Co., Ltd. has a professional after-sales service team that provides comprehensive technical support and equipment maintenance to ensure customers have no worries.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115