Hasung inyanzvi yekugadzira michina yekukanda nekunyungudutsa simbi dzinokosha kubvira muna 2014.

Yakanakisa VIM vacuum induction yekukanda muchina Palladium Platinum vacuum induction inonyungudutsa choto Kambani - Hasung

VIM vacuum induction casting muchina Palladium Platinum vacuum induction melting furnace kana ichienzaniswa neyakafanana zvigadzirwa pamusika, ine mabhenefiti asingaenzaniswi maererano nekuita, mhando, chitarisiko, nezvimwewo, uye inonakidzwa nemukurumbira wakanaka mumusika. Izvo zvinongedzo zveVIM vacuum induction casting muchina Palladium Platinum vacuum induction yekunyungudutsa vira inogona kugadzirwa zvinoenderana nezvaunoda.

Nekugona kwakasimba kwekutsvagisa chigadzirwa nekusimudzira, Shenzhen Hasung Akakosha Metals Equipment Co, Ltd inova nechokwadi chekuti zvigadzirwa zvitsva zvinotangwa nguva nenguva. Chigadzirwa chedu chitsva Hasung VIM vacuum induction casting muchina palladium vacuum induction yekunyungudutsa choto chiri kutengeswa inyaya nyowani uye ine akasiyana maficha. Gold Bar Vacuum Casting Equipment Kuti tikwanise kubudirira kusangana nematambudziko, Shenzhen Hasung Akakosha Metals Equipment Co., Ltd icharamba ichienderera mberi munzira yehunyanzvi hwekuvandudza tekinoroji. Pamusoro pezvo, ichashanda nesimba kuongorora zvinoshanduka zvinodiwa pamusika uye kugadzira zvigadzirwa zviri nani zvevatengi zvinoenderana nezvavanoda.

Yekutanga-Kirasi Hunhu uye Tekinoroji Yeakakosha Metals Equipment Mugadziri muChina.

Application:

Neyedu vacuum kunyungudika sisitimu, iwe unowana nekukurumidza uye nekunaka kunyungudika nekukanda basa. Iyi sisitimu yekunyungudika inoshandiswa pakunyungudutsa goridhe, platinamu, palladium, sirivheri, mhangura ine high vacuum mamiriro.

Tsanangudzo

1. Kugamuchira svikiro frequency induction, nguva yekunyunguduka ipfupi uye kushanda zvakanaka kwakakwira.

2. Kushandiswa kwepamusoro-soro yemvura yakanyorovesa kamuri yekukanda inogona kudzivirira kusvibiswa kwezvinhu zvesimbi uye kusanganiswa kwetsvina, zvichiita kuti zvive zvakakodzera kunyunguduka kwepamusoro-kuchena zvinhu zvesimbi kana izvo zvine nyore oxidizable elements.

3. Kugamuchira mechanical inokurudzira basa pasi pepamusoro pevacuum state, ruvara haruna kupatsanurwa.

4. Iyo graphite crucible inonyungudutswa pasi pepamusoro-kuchena inert gasi kudzivirira, saka kurasikirwa kweiyo oxidation kushoma.

5. Kugamuchira otomatiki kudurura uye kudurura, kushanda kuri nyore.

6. Munguva yekudurura, mold inotora automatic heat kuti ive nechokwadi chekudurura kunaka.

7. Yakashongedzerwa nebasa rekudya rechipiri, rinogona kudzora zvinobudirira nguva yekuwedzera simbi yakaderera.

Kutsanangurwa Kwehunyanzvi

Muenzaniso Nha. | HS-HVQ1 | HS-HVQ2 |

Simba | 15KW | 30KW |

Voltage | 380V ; 50/60Hz | |

Max Temp | 2200°C | |

Nguva yekunyunguduka | 2-3 min. | 4-6 min. |

Temp Accuracy | ±1°C | |

PID temp control | Ehe | |

Capacity | 1kg (Au/Pt) | 4kg (Au/Pt) |

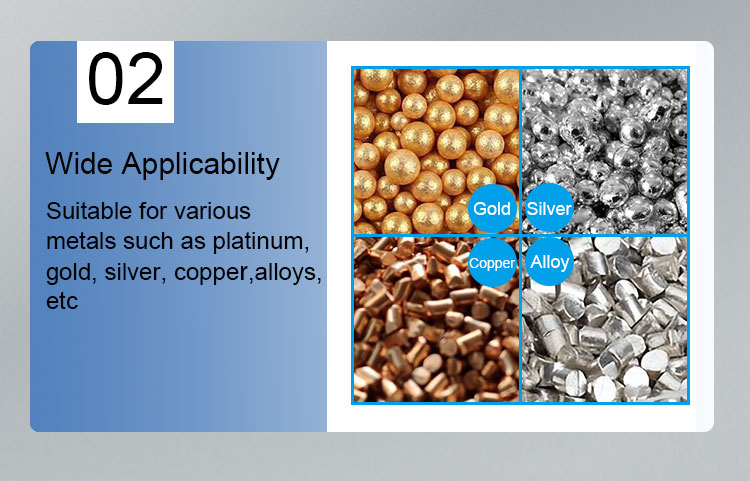

Application | Platinamu, Palladium, Goridhe, sirivha, mhangura uye mamwe alloys | |

Kutonhora mhando | Chiller yemvura (inotengeswa zvakasiyana) | |

Vacuum Degree | vacuum level degree 10-2 Pa, 10-3 Pa, 10-5 Pa, 6.7x10-3Pa, 6.67x10-4 Pa (Inosarudza) | |

Shielding Gasi | Nitrogen/Argon | |

Operation Method | Imwe-kiyi oparesheni yekupedzisa hurongwa hwese, POKA YOKE foolproof system | |

Kudzora System | Mitsubishi PLC+Munhu-muchina interface intelligent control system (optional) | |

Dimensions | 1776x1665x1960mm | |

Kurema | approx. 480kg | |

Mamwe masimba anogona kugadziridzwa.

Musoro: Kuongorora Zvakanakira Metal Vacuum Induction Melting Furnaces

Metal vacuum induction melting (VIM) mavira zvinhu zvakakosha mukugadzirwa kwemhando yepamusoro simbi alloys. Aya mavira epamberi anoshandisa misimboti yekudziya induction uye vacuum tekinoroji kunyungudutsa nekunatsa simbi, zvichikonzera hukuru hwezvinhu. Mune ino blog, isu tinotarisisa nezve mukati mekushanda kweVIM furnaces, mashandisiro avo, uye akawanda mabhenefiti avanopa mukugadzira simbi.

Dzidza nezvesimbi vacuum induction yekunyungudutsa mavira

Metal vacuum induction melting furnace chinhu chakakosha chekunyungudutsa nekunatsa simbi pasi pevacuum mamiriro. Nheyo yekushanda yevira iyi ndeye electromagnetic induction. High-frequency alternating current inopfuura nepacoil kuti ibudise simba remagineti. Kana simbi inofambisa ikaiswa mukati memunda uyu, eddy currents inonyengerera, zvichiita kuti simbi ipise nekukurumidza uye zvakaenzana.

Nzvimbo yevacuum mukati mechoto inoshandisa zvinangwa zvakasiyana-siyana. Kutanga, inodzivirira oxidation uye kusvibiswa kwesimbi yakanyungudutswa, kuve nechokwadi chekugadzirwa kwepamusoro-kuchena alloys. Uyezve, sezvo pasina simba remhepo, tsvina inoputika uye magasi zvinogona kubviswa kubva musimbi yakanyungudutswa, zvichiwedzera kuvandudza kunaka kwayo.

Kushandiswa kwesimbi vacuum induction kunyunguduka choto

Metal vacuum induction melting furnaces inoshandiswa zvakanyanya mukugadzirwa kweakakosha alloys, high-temperature alloys uye high-performance metals. Zvishandiso izvi zvakakosha mumaindasitiri akadai seaerospace, mota, simba uye zvekurapa, izvo zvinoda zvemhando yepamusoro michina, corrosion resistance uye yakanyanya tembiricha kuita.

Kunyanya-yepamusoro-tembiricha alloys ndiyo inotariswa yeVIM choto application. Kazhinji zvichibva pane nickel, cobalt kana simbi, aya alloys epamberi ane simba rakasiyana, kupisa kupisa uye zvinokambaira zvivakwa, zvichiita kuti zvive zvakakosha mukugadzira turbine blades, aerospace zvikamu uye maindasitiri gasi turbines.

Zvakanakira zvesimbi vacuum induction kunyungudutsa vira

1. Hunhu hwakanaka hwezvinhu: Iyo vacuum nharaunda uye kunyatso kudzora kwekunyungudika kunoguma kune alloys ane kuchena kwakanakisa, yakaderera gasi yemukati uye yunifomu kuumbwa, zvichikonzera kuvandudzwa kwemichina uye metallurgical.

2. Enhanced alloy uniformity: Inokurumidza uye inobudirira kusanganiswa kwesimbi yakanyungudutswa mukati mevira reVIM inosimudzira kugoverwa kwakafanana kwezvinhu zvinosanganiswa, kuve nechokwadi chekuenderana kwezvinhu zvezvinhu mukati mekupedzisira kwechigadzirwa.

3. Yakaderedzwa Inclusions uye Kukanganisa: Kusavapo kwezvakasvibiswa zvemuchadenga uye kukwanisa kubvisa tsvina panguva yekunyunguduka kunobatsira zvakanyanya kuderedza inclusions uye kukanganisa, nokudaro kunowedzera kutendeseka kwese kwesimbi.

4. Custom alloy development: VIM furnaces inokwanisa kugadzira alloys etsika anoenderana nezvinodiwa zvemaindasitiri, zvichibvumira kusikwa kwezvinhu zvitsva zvine zvivakwa zvakagadzirirwa.

5. Kushanda kwesimba: Iyo induction yekudziya nzira yakasanganiswa nenzvimbo yevacuum inogona kunyatsoshandisa simba uye kuderedza kupisa kurasikirwa, nekudaro kuchengetedza mari uye zvakatipoteredza zvinobatsira.

6. Kudzora kwemaitiro uye otomatiki: Vhuni dzeVIM dzakashongedzerwa nemasisitimu epamusoro ekudzora anogona kunyatso gadzirisa tembiricha, alloy kuumbwa uye mamwe ma paramita kuti awane anowirirana uye anodzokororwa mhedzisiro.

Muchidimbu, simbi vacuum induction yekunyungudutsa mavira anoita basa rakakosha mukugadzirwa kwemhando yepamusoro simbi alloys kune akasiyana maindasitiri ekushandisa. Kugona kwavo kugadzira zvinhu zvemhando yepamusoro zvine zvimiro zvakasarudzika, zvakasanganiswa nemabhenefiti ekunyatso kudzora maitiro uye kushanda nesimba, zvinoita kuti zvive zvakakosha mukugadzira simbi yemazuva ano. Sezvo tekinoroji ichienderera mberi, mavira eVIM anotarisirwa kuwedzera kuvandudza kuvandudzwa kwezvinhu zvepamberi, kutyaira hunyanzvi uye kufambira mberi mumaindasitiri.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ikambani yeinjiniya yemakanika iri kumaodzanyemba kweChina, muguta rakanaka uye riri kukura nekukurumidza muhupfumi, Shenzhen. Kambani iyi inotungamira muhunyanzvi hwetekinoroji munharaunda yemidziyo yekudziyisa nekukanda simbi dzinokosha neindasitiri yezvinhu zvitsva.

Ruzivo rwedu rwakasimba muhunyanzvi hwekukanda vacuum runotigonesawo kushandira vatengi vemaindasitiri kugadzira simbi ine musanganiswa wakawanda, platinum-rhodium alloy inodiwa ne musanganiswa wakawanda, goridhe nesirivha, nezvimwewo.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Kero: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115