Hasung inyanzvi yekugadzira michina yekukanda nekunyungudutsa simbi dzinokosha kubvira muna 2014.

Midziyo yekunyungudutsa goridhe inonyungudutsa simbi dzinokosha

Hasung TFQ yakatevedzana smelting unit yekunyungudutsa platinamu, rhodium, simbi.

Muenzaniso Nha.: HS-TFQ

Technical data:

| Muenzaniso Nha. | HS-TFQ8 | HS-TFQ10 | HS-TFQ20 |

| Voltage | 380V, 50/60Hz, 3 P | ||

| Simba | 30KW | 30KW/40KW | 50KW/60KW |

| Max. tembiricha | 2100℃ | ||

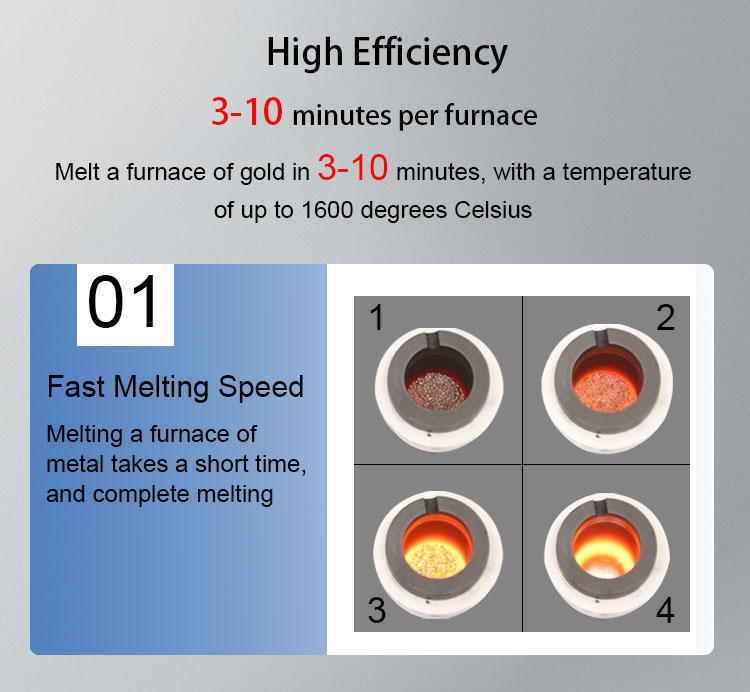

| Kunyunguduka kumhanya | 4-6 min. | 4-6 min. | 5-8 min. |

| Kudzora tembiricha | Infrared pyrometer (kusarudza) | ||

| Temperature control kururama | ±1°C | ||

| Kugona (Pt) | 8kg | 10kg | 20kg |

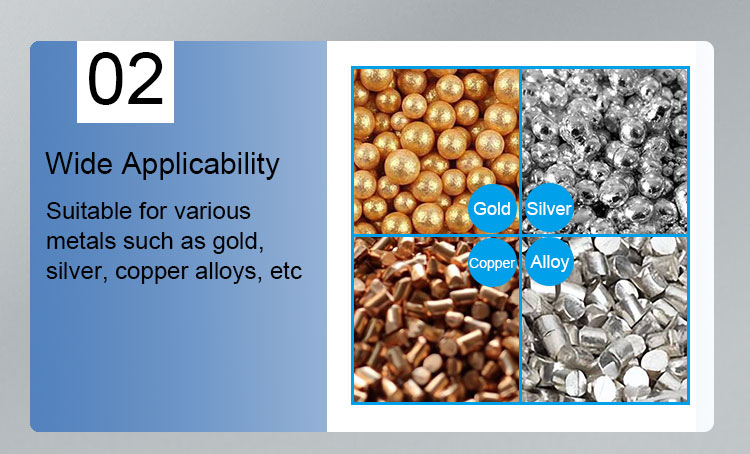

| Application | Platinamu, Palladiu, Rhodium, Goridhe, K goridhe, sirivha, mhangura uye mamwe alloys | ||

| Kutonhora mhando | Chiller yemvura (inotengeswa zvakasiyana) kana Mvura inoyerera (pombi yemvura) | ||

| Dimensions | 115*49*102cm | ||

| 120kg | 140kg | 160kg | |

Ruzivo rwechigadzirwa:

Yakakosha Metals Induction Melting Equipment: Maitiro ekusarudza Yakakodzera Induction Melting Fura yekunyungudutsa Goridhe?

Midziyo yekunyungudutsa induction yakashandura maitiro ekunyungudusa nekunatsa simbi dzakakosha segoridhe, sirivheri neplatinamu. Aya matekinoroji epamusoro anobvumira zvishongo, simbi processors uye makambani emigodhi kunyunguduka uye kuchenesa simbi dzinokosha zviri nyore uye nemazvo, zvichikonzera zvigadzirwa zvemhando yepamusoro uye kuwedzera kubereka. Pakunyungudutsa goridhe, kusarudza iyo chaiyo induction yekunyungudutsa choto kwakakosha kuti uwane izvo zvaunoda. Muchinyorwa chino, isu tichaongorora zvinhu zvakakosha zvekufunga nezvazvo pakusarudza induction yekunyungudutsa yevira yekunyungudutsa goridhe.

1. Kugona uye Kuburikidza

Paunenge uchisarudza induction yekunyungudutsa yevira yekunyungudutsa goridhe, chinhu chekutanga kufunga nezve kugona uye kubuda kunodiwa kuzadzisa zvaunoda chaizvo. Choto chacho chinofanira kukwanisa kubata huwandu hwegoridhe rauri kuda kunyungudusa uye kugadzira munguva yakatarwa. Kunyangwe iwe uri diki jeweler kana hombe mugodhi wekushanda, kune induction inonyungudutsa mavira eakasiyana siyana kuti aenderane nezvinodiwa zvako zvekugadzira. Zvakakosha kuongorora zvaunoda zvazvino uye zveramangwana kuti uve nechokwadi chekuti choto chaunosarudza chinogona kubata huwandu hwegoridhe raunoronga kunyungudika.

2. Kunyunguduka nekukurumidza uye kushanda zvakanaka

Kushanda nesimba uye kumhanya ndizvo zvinhu zvakakosha mukunyunguduka, kunyanya kana uchishanda nesimbi dzakakosha segoridhe. Induction yekunyungudutsa mavira ane kukurumidza kunyunguduka kumhanya uye kushanda kwakanyanya kunogona kuderedza zvakanyanya nguva yekugadzira uye kushandiswa kwesimba. Tarisa choto chakashongedzerwa nehunyanzvi hwekudziisa tekinoroji inonyungudutsa goridhe nekukurumidza uye zvakaenzana, kuve nechokwadi chemhedzisiro uye kushomeka kwekupisa. Pamusoro pezvo, funga nezvesimba rese rekuita kwevira rako kudzikisa mutengo wekushandisa uye kukanganisa kwezvakatipoteredza.

3. Kudzora tembiricha uye kurongeka (kana zvichidikanwa)

Paunenge uchishanda negoridhe, kunyatso kudzora tembiricha kwakakosha kuti uwane kunyungudika kwaunoda uye kukwenenzvera mhedzisiro. Induction inonyungudutsa mavira anofanirwa kupa chaiyo tembiricha yekutarisa uye kutonga masimba kuti ive nechokwadi chekuti goridhe rakanyungudutswa patembiricha yakakwana yekugadzirisa iyo chaiyo alloy. Tarisa mavira ane epamberi tembiricha yekudzora masisitimu uye ma sensors eiyo chaiyo mutemo uye kunyange kudziyisa mukati mekunyungudika.

4. Crucible uye refractory zvinhu

Kusarudzwa kwemacrucibles uye refractory zvinhu mu induction inonyungudika choto kwakakosha kuchengetedza kuchena kwegoridhe rakanyungudutswa uye kuve nechokwadi chekugara kwenguva refu. Macrucibles emhando yepamusoro akagadzirwa nezvinhu zvakaita se graphite, ceramic kana silicon carbide akakosha kushingirira tembiricha yepamusoro uye marara egoridhe rakanyungudutswa. Saizvozvowo, bhiza rechoto refractory rinofanirwa kugadzirwa kuti rimire kuvhunduka kwemafuta uye kuita kwemakemikari, zvichipa nzvimbo yakagadzikana, yakachena yekunyunguduka kwegoridhe.

5. Chengetedzo Zvimiro uye Kutevedzera

Paunenge uchishanda nesimbi dzinokosha, kuchengeteka kunokosha. Izvo zvakakosha kuti usarudze induction yekunyunguduka yevira ine yakazara chengetedzo maficha kuchengetedza anoshanda uye nharaunda yakatenderedza. Tsvaga mavira ane akavakirwa-mukati ekuchengetedza ekudzivirira, akadai sekudzivirira kupisa kwakanyanya, masisitimu ekumisikidza echimbichimbi, uye maficha eutsi. Pamusoro pezvo, ita shuwa kuti choto chinoenderana neindasitiri zviyero uye mirau yekushanda kwakachengeteka uye kuchengetedza kwezvakatipoteredza.

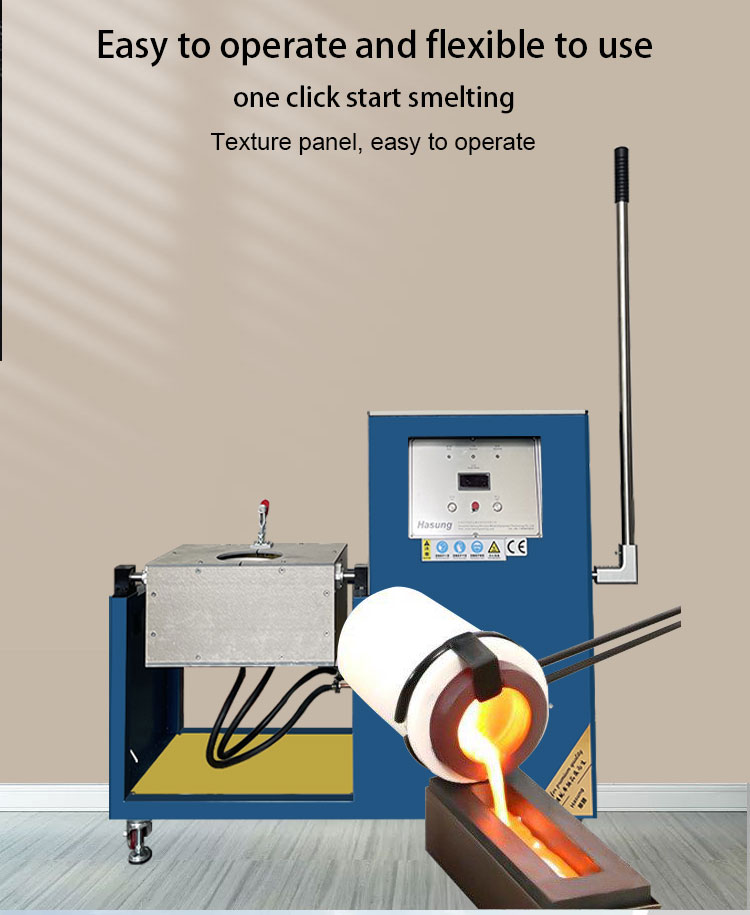

6. Easy kushanda uye kuchengetedza

Kureruka kwekushanda uye kuchengetedza kweiyo induction inonyunguduka choto chimwe chinhu chakakosha kufunga. Mushandisi-ane hushamwari interface, intuitive kudzora uye otomatiki maficha anorerutsa maitiro ekunyunguduka uye kuderedza kudiwa kwekudzidziswa kwakawanda. Pamusoro pezvo, funga kuwanikwa kwekuchengetedza uye kugadziriswa kwezvinhu zvakakosha kuti uderedze nguva yekudzikira uye kuve nechokwadi chehupenyu hurefu hwechoto chako.

7. Kugadzirisa uye kubatanidzwa

Zvichienderana nezvaunoda chaizvo, iwe ungangoda induction yekunyunguduka yevira inogona kugadzirwa kana kubatanidzwa mune yako iripo yekugadzira maitiro. Kunyangwe iko iko kugona kugadzirisa melt paramita, kubatanidza neatomatiki masisitimu, kana kuchinjika kune yakasarudzika melt masisitimu, tsvaga choto chinopa kuchinjika uye kugadzirisa sarudzo kuti isangane nezvido zvako zvega.

8. Mukurumbira uye Tsigiro

Chekupedzisira, pakusarudza choto chekunyungudutsa induction yekunyungudutsa goridhe, funga nezve mukurumbira wemugadziri uye nhanho yerutsigiro yainopa. Tsvaga mutengesi ane mukurumbira ane rekodhi rekodhi mukuunza yepamusoro-soro yakakosha simbi induction midziyo yekunyungudutsa. Pamusoro pezvo, funga nezve kuwanikwa kwerutsigiro rwehunyanzvi, kudzidziswa, uye mushure mekutengesa-sevhisi kuti uve nechokwadi chekuti unogamuchira rubatsiro rwunodiwa uye hunyanzvi hwekuwedzera kushanda kwechoto chako.

Mukupedzisa, kusarudza iyo chaiyo induction yekunyungudutsa choto chekunyungudutsa goridhe isarudzo yakakosha iyo inogona kukanganisa zvakanyanya kunaka, kushanda nesimba uye kuchengetedzeka kwemaitiro ekunyungudutsa. Nekufunga zvinhu zvakaita senge kugona, kumhanya kunyungudika, kudzora tembiricha, zviwanikwa, kuchengetedza maficha, nyore kushanda, kugadzirisa uye kutsigirwa, unogona kuita sarudzo ine ruzivo yekusangana neyako chaiyo yekunyungudika goridhe zvinodiwa. Nekufambira mberi mumidziyo yekunyungudutsa induction, mabhizinesi nemhizha vanogona ikozvino kubatsirwa kubva kune chaiyo uye inoshanda nzira yekunyungudutsa goridhe, zvichikonzera zvigadzirwa zvemhando yepamusoro uye kuwedzera kubereka muindasitiri yesimbi yakakosha.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ikambani yeinjiniya yemakanika iri kumaodzanyemba kweChina, muguta rakanaka uye riri kukura nekukurumidza muhupfumi, Shenzhen. Kambani iyi inotungamira muhunyanzvi hwetekinoroji munharaunda yemidziyo yekudziyisa nekukanda simbi dzinokosha neindasitiri yezvinhu zvitsva.

Ruzivo rwedu rwakasimba muhunyanzvi hwekukanda vacuum runotigonesawo kushandira vatengi vemaindasitiri kugadzira simbi ine musanganiswa wakawanda, platinum-rhodium alloy inodiwa ne musanganiswa wakawanda, goridhe nesirivha, nezvimwewo.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Kero: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115