Isixhobo sokunyibilikisa esinyibilikisayo seSinyibilikisi esiNyibilikayo seSinyibilikisi esiNyibilikayo

Iyunithi yokunyibilikisa uthotho lweHasung TFQ yokunyibilikisa iplatinum, irhodium, kunye nentsimbi.

Inombolo yoMzekelo: HS-TFQ

Idatha yobugcisa:

| Inombolo yoMzekelo | HS-TFQ8 | HS-TFQ10 | HS-TFQ20 |

| I-Voltage | 380V, 50/60Hz, 3 P | ||

| Amandla | 30KW | 30KW/40KW | 50KW/60KW |

| Ubushushu obuphezulu | 2100℃ | ||

| Isantya sokunyibilika | Imizuzu emi-4 ukuya kweyesi-6. | Imizuzu emi-4 ukuya kweyesi-6. | Imizuzu emi-5-8. |

| Ulawulo lobushushu | I-infrared Pyrometer (ukhetho) | ||

| Ukuchaneka kokulawula ubushushu | ±1°C | ||

| Umthamo (Pt) | 8kg | 10kg | 20kg |

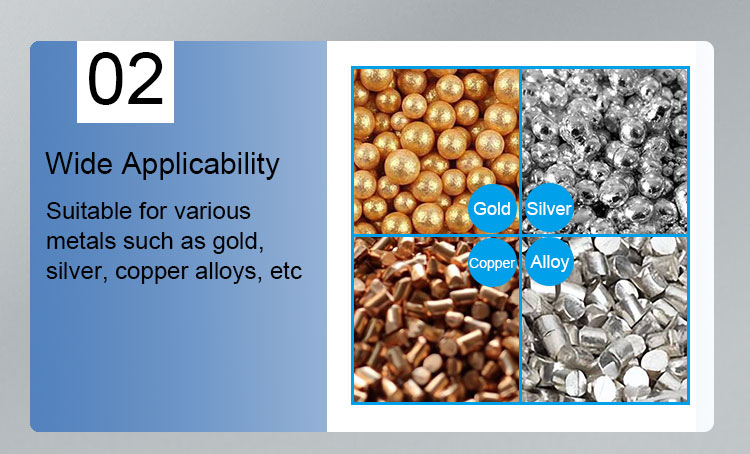

| Isicelo | Iplatinum, iPalladiu, iRhodium, iGolide, igolide yeK, isilivere, ubhedu kunye nezinye ii-alloys | ||

| Uhlobo lokupholisa | Isixhobo sokupholisa amanzi (esithengiswa ngokwahlukeneyo) okanye Amanzi abalekayo (ipompo yamanzi) | ||

| Ubukhulu | 115*49*102cm | ||

| 120kg | 140kg | 160kg | |

Iinkcukacha zemveliso:

Izixhobo zokunyibilikisa isinyithi ezixabisekileyo: Ungayikhetha njani i-Induction Melting Furnace efanelekileyo yokunyibilikisa igolide?

Izixhobo zokunyibilikisa i-induction ziye zaguqula inkqubo yokunyibilikisa nokucoca iintsimbi ezixabisekileyo ezifana negolide, isilivere kunye neplatinum. Ezi teknoloji ziphambili zivumela abenzi bezinto zokuhombisa, abaprosesa besinyithi kunye neenkampani zemigodi ukuba zinyibilikise kwaye zicoce iintsimbi ezixabisekileyo ngokulula nangokufanelekileyo, nto leyo ekhokelela kwiimveliso ezisemgangathweni ophezulu kunye nokwanda kwemveliso. Xa kunyibilikiswa igolide, ukukhetha i-induction melting furnace efanelekileyo kubalulekile ekufezekiseni iziphumo ezifunwayo. Kweli nqaku, siza kuhlola izinto ezibalulekileyo ekufuneka ziqwalaselwe xa ukhetha i-induction melting furnace yokunyibilikisa igolide.

1. Umthamo kunye noPhumo

Xa ukhetha i-induction melting furnace yokunyibilikisa igolide, into yokuqala ekufuneka uyiqwalasele kumthamo kunye nemveliso efunekayo ukuhlangabezana neemfuno zakho ezithile. I-furnace kufuneka ikwazi ukugcina ubungakanani begolide oceba ukuyinyibilikisa kwaye uyicubungule ngexesha elithile. Nokuba ungumenzi wezinto zamatye amancinci okanye umsebenzi omkhulu wokwemba, kukho ii-induction melting furnaces ezahlukeneyo ukuze zihambelane neemfuno zakho zemveliso. Kubalulekile ukuvavanya iimfuno zakho zangoku nezexesha elizayo ukuqinisekisa ukuba i-furnace oyikhethayo inokusingatha ubungakanani begolide oceba ukuyinyibilikisa.

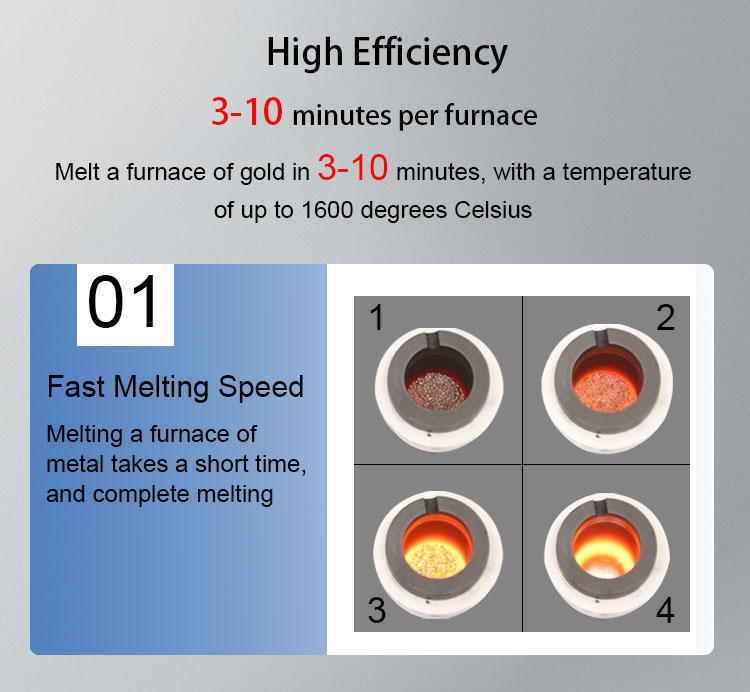

2. Isantya sokunyibilika kunye nokusebenza kakuhle

Ukusebenza kakuhle kunye nesantya zezona zinto zibalulekileyo kwinkqubo yokunyibilika, ingakumbi xa usebenza ngeentsimbi ezixabisekileyo ezifana negolide. Ii-induction melting furnaces ezinesantya esikhawulezayo sokunyibilika kunye nokusebenza kakuhle kunokunciphisa kakhulu ixesha lokuvelisa kunye nokusetyenziswa kwamandla. Khangela i-furnace exhotyiswe ngetekhnoloji yokufudumeza ye-induction ephucukileyo enyibilikisa igolide ngokukhawuleza nangokulinganayo, ukuqinisekisa iziphumo ezihambelanayo kunye nokulahleka kobushushu okuncinci. Ukongeza, cinga ngokusebenza kakuhle kwamandla kwesithando sakho ukuze unciphise iindleko zokusebenza kunye nempembelelo yokusingqongileyo.

3. Ulawulo lobushushu kunye nokuchaneka (ukuba kuyimfuneko)

Xa usebenza ngegolide, ulawulo oluchanekileyo lobushushu lubalulekile ekufezekiseni iziphumo ezifunwayo zokunyibilika nokucocwa. Ii-induction melting furnaces kufuneka zibonelele ngokubekwa esweni kobushushu obuchanekileyo kunye nokukwazi ukulawula ukuqinisekisa ukuba igolide inyibilikisiwe kubushushu obufanelekileyo bokucubungula i-alloy ethile. Khangela ii-furnaces ezineenkqubo zokulawula ubushushu eziphambili kunye nee-sensors zokulawula ngokuchanekileyo kunye nokufudumeza kuyo yonke inkqubo yokunyibilika.

4. Izinto ezivuthayo nezinganyangekiyo

Ukukhethwa kwezinto eziqhotsiweyo kunye nezinto eziqhotsiweyo kwisithando sokunyibilikisa igolide kubaluleke kakhulu ekugcineni ubunyulu begolide eqhotsiweyo nokuqinisekisa ukuqina kwexesha elide. Izinto eziqhotsiweyo ezikumgangatho ophezulu ezenziwe ngezinto ezifana ne-graphite, i-ceramic okanye i-silicon carbide zibalulekile ekumelaneni namaqondo obushushu aphezulu kunye nendalo yokubola kwegolide eqhotsiweyo. Ngokufanayo, ulwelo oluqhotsiweyo lwesithando kufuneka luyilwe ukuze lumelane noxinzelelo lobushushu kunye neempendulo zeekhemikhali, lubonelele ngendawo yokunyibilikisa ezinzileyo necocekileyo yegolide.

5. Iimpawu zoKhuseleko kunye nokuThotyelwa kweMithetho

Xa usebenza ngeentsimbi ezixabisekileyo, ukhuseleko lubaluleke kakhulu. Kubalulekile ukukhetha isithando sokunyibilikisa i-induction esineempawu zokhuseleko ezipheleleyo ukukhusela umqhubi kunye nokusingqongileyo okungqongileyo. Khangela izithando ezinezixhobo zokulawula ukhuseleko ezakhelwe ngaphakathi, ezifana nokukhusela ubushushu obugqithisileyo, iinkqubo zokuvala ungxamiseko, kunye nezixhobo zokukhupha umsi. Ukongeza, qinisekisa ukuba isithando siyahambelana nemigangatho kunye nemigaqo yoshishino yokusebenza ngokukhuselekileyo kunye nokuzinza kokusingqongileyo.

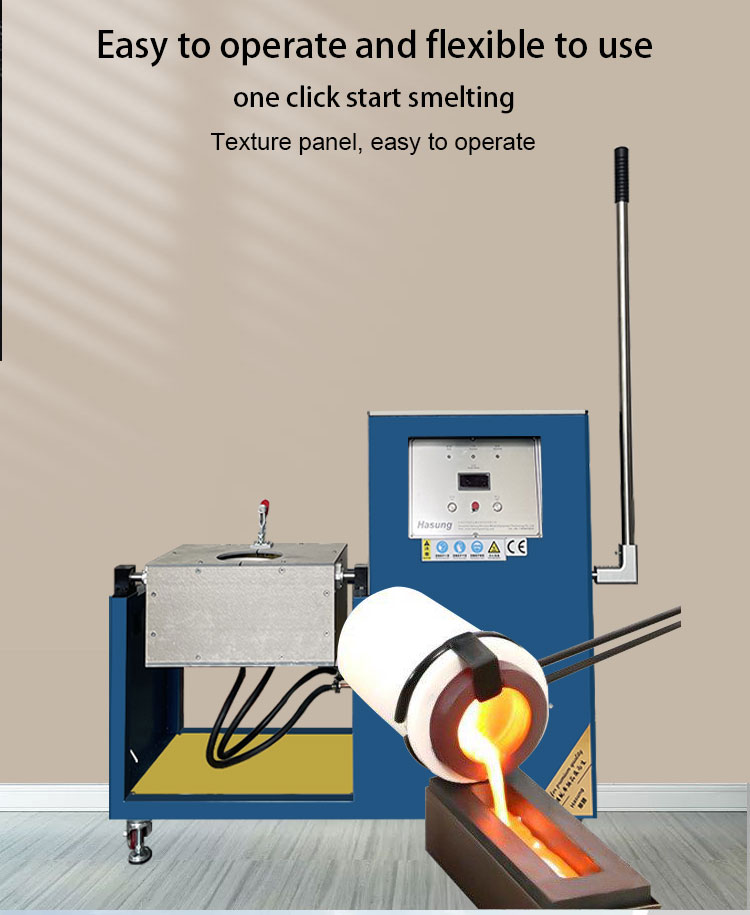

6. Kulula ukuyisebenzisa nokuyigcina ikwimeko entle

Ukulula kokusebenza nokugcinwa kwesithando sokunyibilikisa i-induction yenye into ebalulekileyo ekufuneka iqwalaselwe. Ujongano olusebenziseka lula, ulawulo oluqondakalayo kunye neempawu ezizenzekelayo zenza lula inkqubo yokunyibilikisa kwaye zinciphise isidingo soqeqesho olubanzi. Ukongeza, cinga ngokufikeleleka kulondolozo kunye nokulungiswa kwezinto ezibalulekileyo ukuze unciphise ixesha lokungasebenzi kwaye uqinisekise ukuba isithando sakho sihlala ixesha elide.

7. Ukwenziwa ngokwezifiso kunye nokudibanisa

Ngokuxhomekeke kwiimfuno zakho ezithile, unokufuna i-induction melting furnace enokwenziwa ngokwezifiso okanye idityaniswe kwinkqubo yakho yemveliso ekhoyo. Nokuba kukukwazi ukulungisa iiparameters ze-melt, ukudibanisa neenkqubo ezenzekelayo, okanye ukuziqhelanisa neendlela ezizodwa ze-melt, khangela i-furnace enika ukhetho lokuguquguquka kunye nokwenza ngokwezifiso ukuhlangabezana neemfuno zakho.

8. Udumo kunye neNkxaso

Okokugqibela, xa ukhetha isithando sokunyibilikisa igolide, cinga ngodumo lomenzi kunye nenqanaba lenkxaso eliyinikayo. Khangela umthengisi othembekileyo onerekhodi eliqinisekisiweyo lokubonelela ngezixhobo zokunyibilikisa isinyithi esixabisekileyo esikumgangatho ophezulu. Ukongeza, cinga ngokufumaneka kwenkxaso yobugcisa, uqeqesho, kunye nenkonzo yasemva kokuthengisa ukuqinisekisa ukuba ufumana uncedo olufunekayo kunye nobuchule bokuphucula ukusebenza kwesithando sakho.

Ukuqukumbela, ukukhetha isithando sokunyibilikisa igolide esifanelekileyo sokunyibilikisa igolide sisigqibo esibalulekileyo esinokuchaphazela kakhulu umgangatho, ukusebenza kakuhle kunye nokhuseleko lwenkqubo yokunyibilikisa. Ngokuqwalasela izinto ezinje ngomthamo, isantya sokunyibilikisa, ulawulo lobushushu, izixhobo, iimpawu zokhuseleko, ukulula kokusebenza, ukwenza ngokwezifiso kunye nenkxaso, ungenza ukhetho olunolwazi lokuhlangabezana neemfuno zakho ezithile zokunyibilikisa igolide. Ngokuphucuka kwezixhobo zokunyibilikisa igolide, amashishini kunye neengcibi ngoku zinokungenelwa kwinkqubo yokunyibilikisa igolide echanekileyo nesebenzayo, okubangela iimveliso ezikumgangatho ophezulu kunye nokwanda kwemveliso kushishino lweentsimbi ezixabisekileyo.

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjineli boomatshini ekwimazantsi eTshayina, kwisixeko esihle nesikhula ngokukhawuleza kwezoqoqosho, iShenzhen. Le nkampani yinkokheli kwezobuchwepheshe kwicandelo lezixhobo zokufudumeza nokuthunga izixhobo zesinyithi esixabisekileyo kunye neshishini lezinto ezintsha.

Ulwazi lwethu olomeleleyo kubuchwepheshe bokuphosa i-vacuum lusenza sikwazi ukunceda abathengi bemizi-mveliso ukuphosa intsimbi exutywe kakhulu, i-platinum-rhodium alloy efunekayo kakhulu, igolide nesilivere, njl.

Umnxeba: +86 17898439424

I-imeyile:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Idilesi: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115