UHasung ungumkhiqizi womshini wokubumba nokuncibilikisa izinsimbi eziyigugu ochwepheshe kusukela ngo-2014.

Isisetshenziswa Sokuncibilikisa Esincibilikisayo Sezinsimbi Eziyigugu Ezincibilikisa Igolide

Iyunithi yokuncibilikisa yochungechunge lwe-Hasung TFQ yokuncibilikisa iplatinamu, i-rhodium, insimbi.

Inombolo yemodeli: HS-TFQ

Idatha yobuchwepheshe:

| Imodeli No. | HS-TFQ8 | HS-TFQ10 | HS-TFQ20 |

| Amandla kagesi | 380V, 50/60Hz, 3 P | ||

| Amandla | 30KW | 30KW/40KW | 50KW/60KW |

| Ubukhulu. izinga lokushisa | 2100℃ | ||

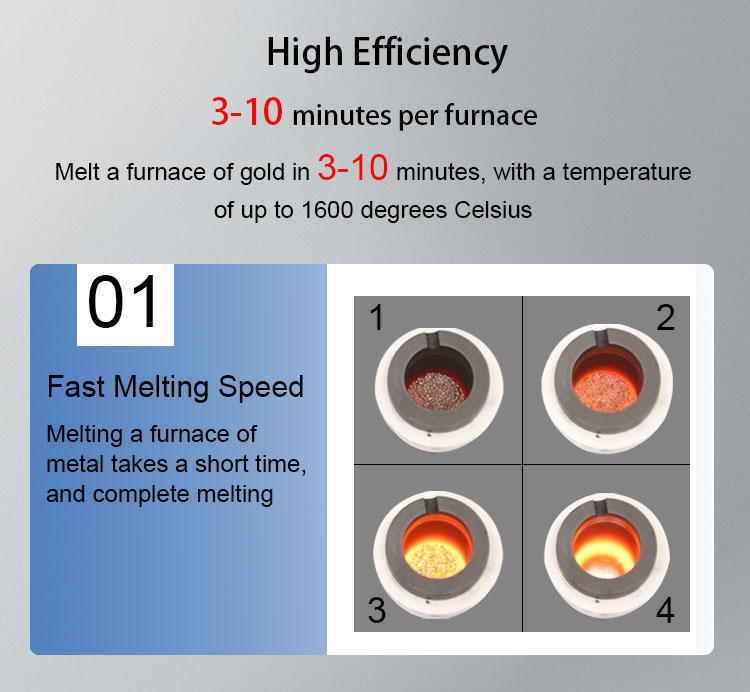

| Isivinini sokuncibilika | 4-6 imiz. | 4-6 imiz. | 5-8 imiz. |

| Ukulawula izinga lokushisa | I-Infrared Pyrometer (uyazikhethela) | ||

| Ukunemba kokulawula izinga lokushisa | ±1°C | ||

| Amandla (Pt) | 8kg | 10kg | 20kg |

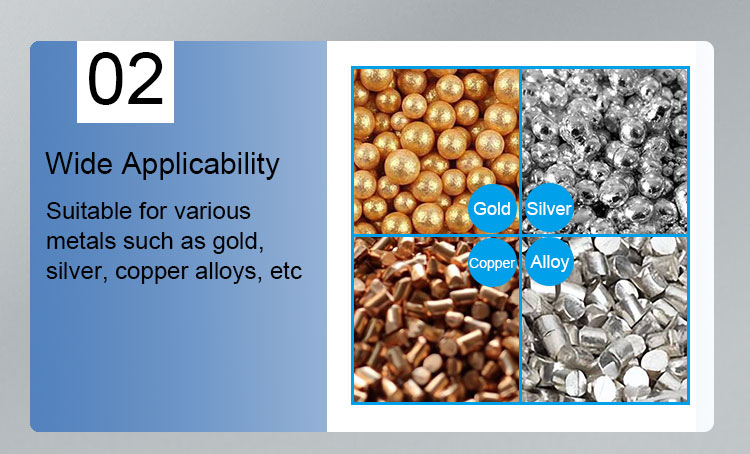

| Isicelo | I-Platinum, i-Palladiu, i-Rhodium, igolide, i-K igolide, isiliva, ithusi namanye ama-alloys | ||

| Uhlobo lokupholisa | I-water chiller (ithengiswa ngokwehlukana) noma Amanzi agijimayo (ipompo yamanzi) | ||

| Ubukhulu | 115*49*102cm | ||

| 120kg | 140kg | 160kg | |

Imininingwane yomkhiqizo:

Izisetshenziswa Zokuncibilikisa Izinsimbi Eziyigugu: Ungasikhetha Kanjani Isithando Somlilo Esincibilikisa Esilungile Ukuze Uncibilike Igolide?

Imishini yokuncibilikisa induction induction isiguqule inqubo yokuncibilika kanye nokucwengisiswa kwezinsimbi eziyigugu njengegolide, isiliva neplatinamu. Lobu buchwepheshe obuthuthukisiwe buvumela abakha ubucwebe, ama-metal processors kanye nezinkampani zezimayini ukuthi zincibilike futhi zihlanze izinsimbi eziyigugu kalula nangempumelelo, okuholela emikhiqizweni yekhwalithi ephezulu kanye nokwanda kokukhiqiza. Lapho kuncibilika igolide, ukukhetha isithando somlilo esincibilikisayo esilungile kubalulekile ukuze kuzuzwe imiphumela oyifunayo. Kulesi sihloko, sizohlola izici ezibalulekile okufanele zicatshangelwe lapho ukhetha isithando somlilo sokuncibilikisa sokuncibilikisa igolide.

1. Amandla kanye Nokuphumelela

Uma ukhetha isithando somlilo sokuncibilika sokuncibilikiswa kwegolide, into yokuqala okufanele uyicabangele umthamo kanye nokuphumayo okudingekayo ukuze kuhlangatshezwane nezidingo zakho ezithile. Isithando somlilo kufanele sikwazi ukubamba inani legolide ohlose ukulincibilikisa futhi silicubungule ngesikhathi esibekiwe. Noma ngabe ungumcwebi wobucwebe obuncane noma umsebenzi omkhulu wezimayini, kunezindawo zokuncibilikisa zokungeniswa zamakhono ahlukahlukene ukuze zivumelane nezidingo zakho zokukhiqiza. Kubalulekile ukuhlola izidingo zakho zamanje nezesikhathi esizayo ukuze uqinisekise ukuthi isithando somlilo osikhethayo singakwazi ukuphatha inani legolide ohlela ukulincibilikisa.

2. Isivinini sokuncibilika nokusebenza kahle

Ukusebenza kahle nesivinini yizici ezibalulekile enqubweni yokuncibilika, ikakhulukazi uma usebenza ngezinsimbi eziyigugu njengegolide. Iziko lokuncibilika lokungeniswa elinesivinini sokuncibilika okusheshayo nokusebenza kahle okuphezulu kunganciphisa kakhulu isikhathi sokukhiqiza nokusetshenziswa kwamandla. Bheka isithando somlilo esifakwe ubuchwepheshe bokushisisa obusezingeni eliphezulu obuncibilikisa igolide ngokushesha nangokulinganayo, okuqinisekisa imiphumela engaguquki kanye nokulahlekelwa ukushisa okuncane. Ukwengeza, cabanga ukusebenza kahle kwamandla kwesithando sakho somlilo ukuze unciphise izindleko zokusebenza kanye nomthelela wemvelo.

3. Ukulawula izinga lokushisa nokunemba (uma kudingeka)

Lapho usebenza ngegolide, ukulawulwa kwezinga lokushisa okunembile kubalulekile ukuze kuzuzwe imiphumela yokuncibilika nokucwengisiswa oyifunayo. Iziko lokuncibilika kwe-induction kufanele zinikeze ukuqapha okunembile kwezinga lokushisa namandla okulawula ukuze kuqinisekiswe ukuthi igolide liyancibilika ngezinga lokushisa elilungile lokucubungula ingxubevange ethile. Bheka amaziko anezinhlelo zokulawula izinga lokushisa ezithuthukisiwe nezinzwa zokulawula okunembile ngisho nokushisisa phakathi nenqubo yokuncibilika.

4. Izinto ezisetshenziswayo neziqinile

Ukukhethwa kweziphambano nezinto eziphikisayo esithandweni sokuncibilika sokungeniswa kubalulekile ukuze kugcinwe ukuhlanzeka kwegolide elincibilikisiwe nokuqinisekisa ukuqina kwesikhathi eside. Izikhilimu zekhwalithi ephezulu ezenziwe ngezinto ezifana ne-graphite, i-ceramic noma i-silicon carbide zibalulekile ukuze zimelane nezinga lokushisa eliphezulu kanye nemvelo yokubola yegolide elincibilikisiwe. Ngokufanayo, ulwelwesi lwesithando somlilo oluphikisayo kufanele ludizayinelwe ukumelana nokushaqeka kokushisa nokushintshashintsha kwamakhemikhali, lunikeze indawo ezinzile, ehlanzekile yokuncibilika kwegolide.

5. Izici Zokuvikeleka Nokuthobelana

Lapho usebenza ngezinsimbi eziyigugu, ukuphepha kubaluleke kakhulu. Kubalulekile ukukhetha isithando somlilo se-induction esinezici zokuphepha eziphelele ukuze kuvikelwe u-opharetha nendawo ezungezile. Bheka amaziko anezilawuli zokuphepha ezakhelwe ngaphakathi, njengokuvikela ukushisa ngokweqile, amasistimu okuvalwa kwezimo eziphuthumayo, nezici zokukhipha intuthu. Ukwengeza, qinisekisa ukuthi isithando somlilo siyahambisana namazinga nemithetho yemboni yokusebenza okuphephile kanye nokusimama kwemvelo.

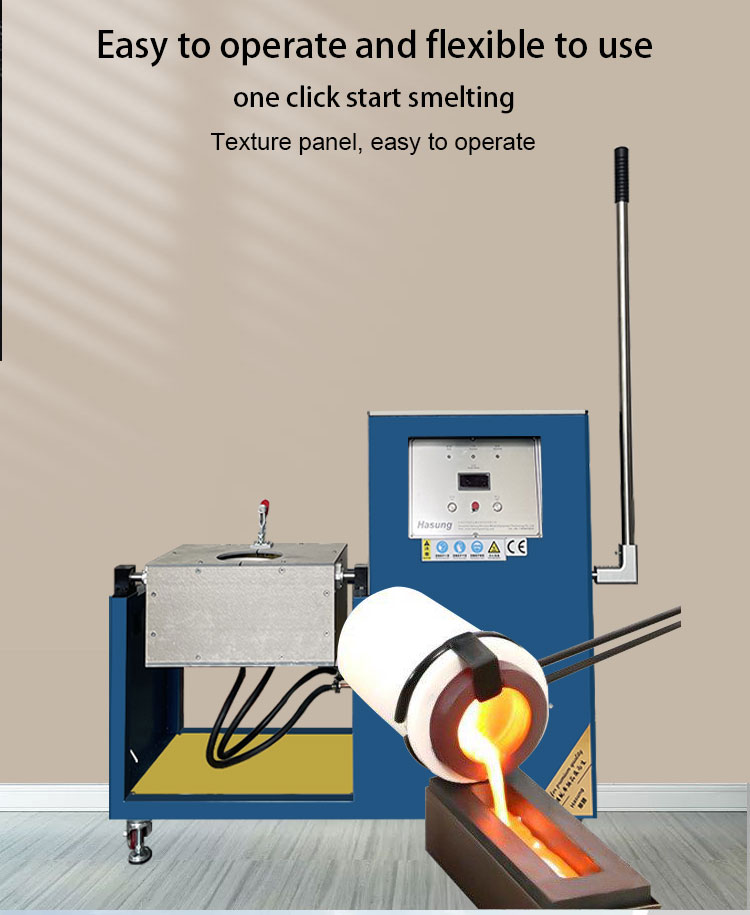

6. Kulula ukuyisebenzisa nokuyinakekela

Ukusebenziseka kalula kanye nokugcinwa kwesithando somlilo esincibilikisa i-induction kungenye into ebalulekile ecatshangelwayo. Isixhumi esibonakalayo esisebenziseka kalula, izilawuli ezinembile nezici ezizenzakalelayo zenza kube lula inqubo yokuncibilika futhi zinciphise isidingo sokuqeqeshwa okubanzi. Ukwengeza, cabangela ukufinyeleleka ekunakekeleni nasekulungiseni izingxenye ezibalulekile ukuze unciphise isikhathi sokuphumula futhi uqinisekise ubude bokuphila kwesithando sakho.

7. Ukwenza ngokwezifiso nokuhlanganiswa

Ngokuya ngezidingo zakho ezithile, ungase udinge isithando somlilo esincibilikayo esingenziwe ngokwezifiso noma sihlanganiswe nenqubo yakho yokukhiqiza ekhona. Kungakhathaliseki ukuthi ikhono lokulungisa amapharamitha ancibilikayo, ukuhlanganisa namasistimu azenzakalelayo, noma ukuzivumelanisa nezimo eziyingqayizivele zokuncibilika, bheka isithando somlilo esinikeza ukuguquguquka nezinketho zokwenza ngokwezifiso ukuhlangabezana nezidingo zakho ngazinye.

8. Idumela Nokwesekwa

Okokugcina, lapho ukhetha isithando somlilo sokuncibilika se-induction sokuncibilikisa igolide, cabangela idumela lomkhiqizi kanye nezinga lokusekela elihlinzekayo. Bheka umphakeli ohlonishwayo onerekhodi elifakazelwe ekuletheni okokusebenza okuncibilikisa kwensimbi okuyigugu kwekhwalithi ephezulu. Ukwengeza, cabangela ukutholakala kosekelo lobuchwepheshe, ukuqeqeshwa, kanye nesevisi yangemva kokuthengisa ukuze uqinisekise ukuthi uthola usizo oludingekayo kanye nobuchwepheshe bokukhulisa ukusebenza kwesithando somlilo sakho.

Sengiphetha, ukukhetha isithando somlilo esifanele sokuncibilikiswa kwegolide kuyisinqumo esibucayi esingaba nomthelela omkhulu kwikhwalithi, ukusebenza kahle kanye nokuphepha kwenqubo yokuncibilikisa. Ngokucabangela izici ezifana nomthamo, isivinini sokuncibilika, ukulawulwa kwezinga lokushisa, izinto zokwakha, izici zokuphepha, ukusebenza kalula, ukwenza ngendlela oyifisayo nokusekela, ungenza ukukhetha unolwazi ukuhlangabezana nezidingo zakho ezithile zokuncibilika kwegolide. Ngokuthuthuka kwemishini yokuncibilikisa yokungeniswa, amabhizinisi nezingcweti manje sebengakwazi ukuzuza ohlelweni olunembayo nephumelelayo lokuncibilikisa igolide, okuholela emikhiqizweni yekhwalithi ephezulu kanye nokukhiqiza okukhulayo embonini yensimbi eyigugu.

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjiniyela bemishini etholakala eningizimu yeShayina, edolobheni elihle nelikhula ngokushesha kwezomnotho, iShenzhen. Le nkampani ingumholi kwezobuchwepheshe emkhakheni wemishini yokushisa nokukhipha izinsimbi eziyigugu kanye nemboni yezinto ezintsha.

Ulwazi lwethu oluqinile kubuchwepheshe bokuphonswa kwe-vacuum lusenza sikwazi ukukhonza amakhasimende ezimboni ukuze afake insimbi exutshwe kakhulu, i-platinum-rhodium alloy edingekayo nge-vacuum ephezulu, igolide nesiliva, njll.

Ucingo: +86 17898439424

I-imeyili: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Ikheli: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115