Hasung ke Moetsi oa Mechini ea ho Qhibilihisa le ho Fokotsa Tšepe ea Bohlokoa ho tloha ka 2014.

Lisebelisoa tsa indasteri ea mechini ea tšepe e tsoelang pele ea tšepe le maemo a ho lahlela vacuum?

◪ Indasteri ea mabenyane

Mochini o tsoelang pele oa ho lahla o ka hlahisa li-ingots, lithapo le lintlha tsa tšepe tsa bohlokoa tse kang khauta, silevera le platinum, ho netefatsa bohloeki bo phahameng ba thepa le boreleli ba holim'a metsi, ho finyella litlhoko tsa ho etsa mabenyane a phahameng, ha ho ntse ho fokotsa tahlehelo ea thepa le ho ntlafatsa katleho ea tlhahiso.

◪ Indasteri ea elektronike

Ha ho etsoa li-semiconductors, li-microelectronics le likarolo tsa elektronike tse nepahetseng, mechine ea tšepe ea bohlokoa e tsoelang pele e ka hlahisa lithapo tse tlamang tsa khauta le silevera, li-conductive pastes, lisebelisoa tsa motlakase, joalo-joalo, ho netefatsa hore ho na le conductivity e ntle haholo le ho hanyetsa oxidation, e loketseng mekhoa ea bohlokoa e kang ho paka chip le lihokelo tsa potoloho.

◪ Indasteri ea lisebelisoa tsa bongaka

Litšepe tsa bohlokoa tse kang polatinamo, palladium le khauta li sebelisoa hangata ho lisebelisoa tsa bongaka tsa boemo bo holimo joalo ka li-electrode tsa pacemaker le lisebelisoa tsa ho lokisa meno ka lebaka la ts'ebetso ea tsona e ntle ea biocompatibility le ho hanyetsa ho bola. Mochini oa tšepe oa bohlokoa o tsoelang pele oa ho lahla o ka hlahisa lisebelisoa tsa tšepe tsa boleng bo holimo, tse se nang tšilafalo tse fihlelang litekanyetso tsa boemo ba bongaka.

◪ Liindasteri tsa Aerospace le Sesole

Mocheso o phahameng, khatello e phahameng le tikoloho e senyang haholo, li-alloys tsa tšepe tsa bohlokoa (tse kang platinum rhodium thermocouples le khauta e thehiloeng holim'a mocheso o phahameng oa mocheso) ke lisebelisoa tsa bohlokoa bakeng sa li-sensor tsa sefofane le likarolo tsa enjene. Ho tsoela pele ho lahla litšepe tsa bohlokoa ho ka hlahisa li-alloys tse sebetsang hantle ka mokhoa o tsitsitseng, ho etsa bonnete ba ho lumellana ha lintho le ho tšepahala.

◪ Indasteri e ncha ea matla

Tlhokahalo ea litšepe tsa bohlokoa joalo ka li-catalysts tsa platinum le paste ea silevera e ntse e eketseha ka har'a sele ea mafura, li-solar cell le liindasteri tsa matla a hydrogen. Mochini oa bohlokoa oa tšepe o tsoelang pele oa ho lahla o ka lokisa lisebelisoa tsa boleng bo holimo, oa ntlafatsa ts'ebetso le nako ea bophelo ea lisebelisoa tse ncha tsa matla.

Theknoloji e tsoelang pele ea Vacuum e ka qoba ho oxidation ea lintho tse bonahalang, porosity le tšilafalo, 'me e loketse maemo a latelang a tlhokahalo e phahameng:

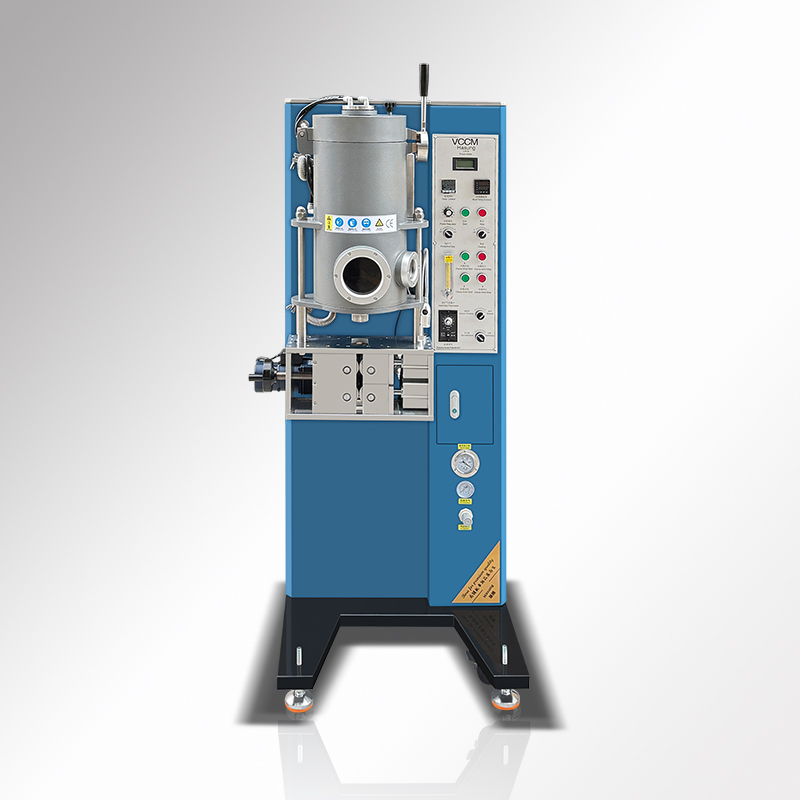

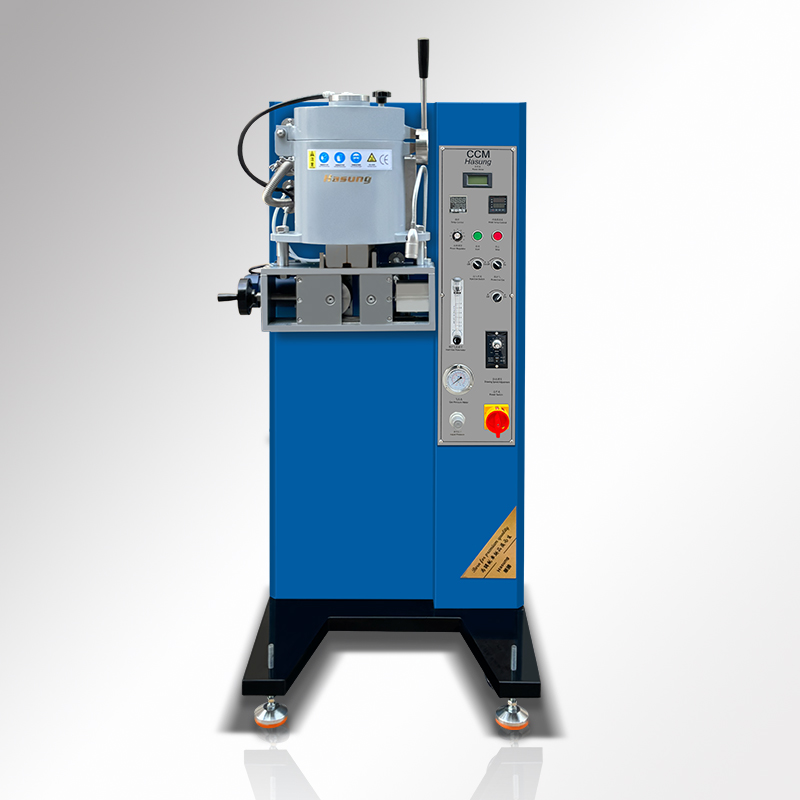

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ke khamphani ea boenjiniere ba mechini e fumanehang ka boroa ho Chaena, motseng o motle le o holang ka potlako ka ho fetisisa moruong, Shenzhen. Khamphani ke moetapele oa theknoloji lefapheng la lisebelisoa tsa ho futhumatsa le ho lahla tšepe ea bohlokoa le indasteri ea thepa e ncha.

Tsebo ea rona e matla ea theknoloji ea ho lahla ka vacuum e re nolofalletsa ho sebeletsa bareki ba indasteri ho lahla tšepe e kopantsoeng ka bongata, motsoako oa platinum-rhodium o hlokahalang ka vacuum e ngata, khauta le silevera, jj.

Mohala: +86 17898439424

E-mail: sales@hasungmachinery.com.

WhatsApp: 0086 17898439424

Aterese: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115