How is gold refined into gold bars? A comprehensive look at the full process of Hasung gold bar production

In the precious metal casting industry, precision and efficiency determine a company's core competitiveness. Traditional gold bar production processes, plagued by weighing errors, surface defects, and process instability, have long plagued many manufacturers. Now, let's take a professional look at a revolutionary solution—the Hasung Gold Bar Casting Line—and see how it redefines the standard of excellence in gold casting with innovative technology.

1. How to weigh every inch of gold accurately to the millimeter?

Any precision gold bar casting process requires a perfect beginning. The Hasung production line begins with the ultimate pursuit of precise weighing.

△Core Equipment: Hasung Precious Metal Granulator

△Function: Breaking Down the Whole into Parts: The Art of Precision Weighing

The Hasung Precious Metal Granulator utilizes unique centrifugal atomization technology to form uniform, fine gold particles under an inert gas atmosphere. Its innovative cooling system ensures that each gold particle achieves perfect geometric specifications, achieving 99.8% particle size consistency. This groundbreaking design enables subsequent weighing accuracy to 0.001 gram, completely eliminating the weighing error issues associated with traditional processes.

2. How to Cast a Mirror-Perfect Gold Bar Blank?

Once the precise gold grains are prepared, the true precision casting journey officially begins. Here, Hasung demonstrates its exceptional expertise in thermal control.

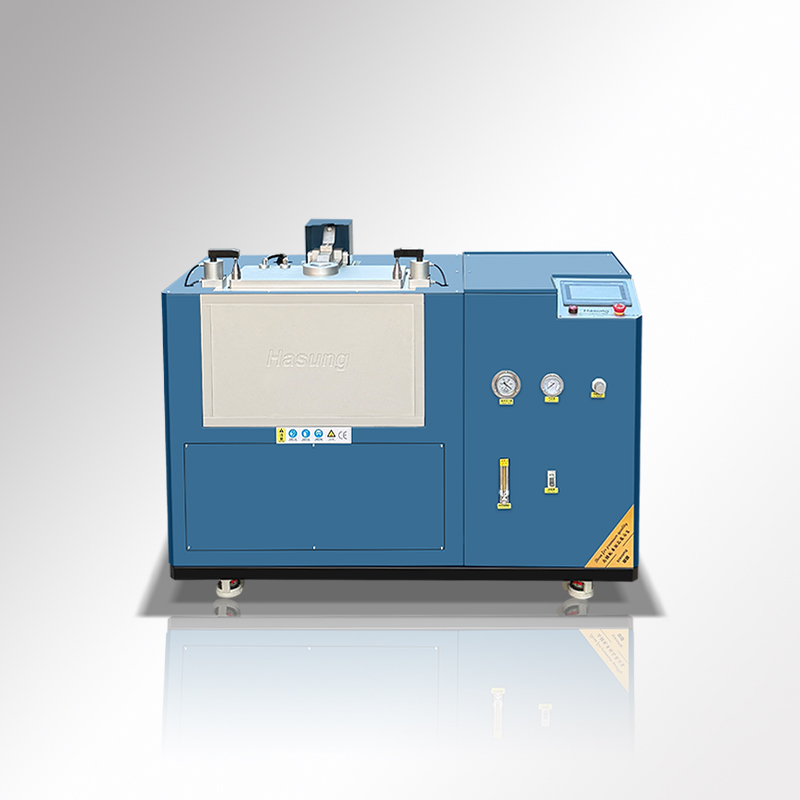

△Core Equipment: Hasung Vacuum Ingot Caster

△Function: Defect-Free Surface, Ultimately Pure Internal Quality

The Hasung Vacuum Ingot Caster integrates multiple patented technologies:

A bipolar vacuum system ensures an oxygen content in the melting environment below 5ppm

An intelligent temperature control system achieves precise temperature control within ±2°C

Specialized graphite molds undergo nano-level surface treatment

Stepped cooling technology ensures uniform solidification of the gold bar from the inside out

These innovative technologies collectively ensure that every gold bar produced is: mirror-like in appearance, free of bubbles, flaws, and gold material loss.

3. How to Inscribe Every Gold Bar with Words and Symbols

A perfect gold bar blank requires inscription with words and symbols. Hasung's marking system provides the perfect solution.

△Core Equipment: Hasung Stamping Machine

△Function: Clear, permanent, authoritative stamping, and irreplaceable anti-counterfeiting protection

The Hasung stamping machine plays a key role in gold bar production:

First, it stamps brand, purity, weight, and other identification features, ensuring anti-counterfeiting and branding, making it easier for consumers to identify the product.

Second, it ensures a high degree of uniformity in the shape, size, and texture of gold bars, meeting the standardization requirements of the financial and collectible markets and facilitating circulation and trading.

Third, the refined embossing enhances the quality and value of gold bars, enhancing their appeal as both an investment and collector's item. It also connects the smelting and forming processes, completing the final refinement of gold bar production.

4. How to Achieve Accurate Traceability and Asset Management?

In the modern financial system, every gold bar requires precise identity management. Hasung's intelligent marking system sets a new standard.

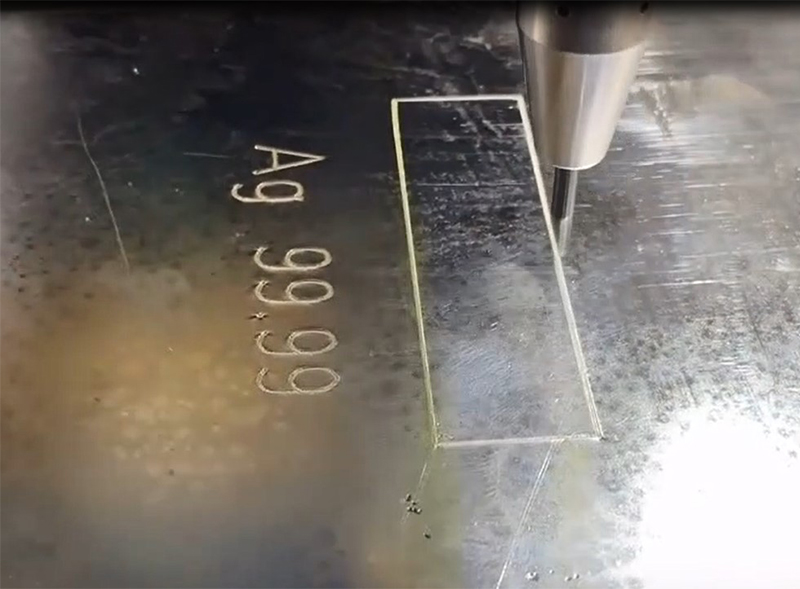

△Core Equipment: Hasung Laser Serial Number Marking Machine

△Function: Permanent Identification, Intelligent Traceability Management

The Hasung laser marking machine utilizes fiber laser technology to engrave clear and permanent serial information on the surface of gold bars:

A unique combination of a QR code and serial number

A production timestamp accurate to the second

Batch code and quality grade identification

A deeply controllable anti-counterfeiting mark

This information is directly connected to the company's asset management system, enabling full lifecycle traceability from production to distribution.

5. Why Choose the Hasung Gold Bar Casting Line?

After rigorous testing and verification, the Hasung gold bar casting line has become a new benchmark in the industry. Its outstanding performance is reflected in:

Technological Innovation Advantages:

>95% automation across the entire production line significantly reduces labor costs.

>Energy consumption is 25% lower than traditional equipment, embracing green manufacturing.

>Modular design supports flexible production and can quickly adapt to different specifications.

Quality Assurance System:

>Each unit undergoes 168 hours of continuous testing before shipment.

>Comprehensive after-sales training and technical support are provided.

>Lifetime maintenance on key components ensures long-term stable operation.

Return on Investment:

>Product quality rate increases to 99.95%.

>Production efficiency increases by over 40%.

>Payback period shortened to approximately three months.

The Hasung gold bar casting production line is more than just a piece of equipment; it is a strategic partner that helps companies enhance their competitiveness and create greater value. Choosing Hasung means choosing superior quality, technological innovation, and the future of the industry.

Whether you are a precious metals refiner, mint, or jewelry manufacturer, Hasung can provide you with the most suitable customized solutions. Let us work together to usher in a new era in precious metals processing and manufacturing.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115