How does a vacuum ingot casting machine create “perfect” gold and silver ingots?

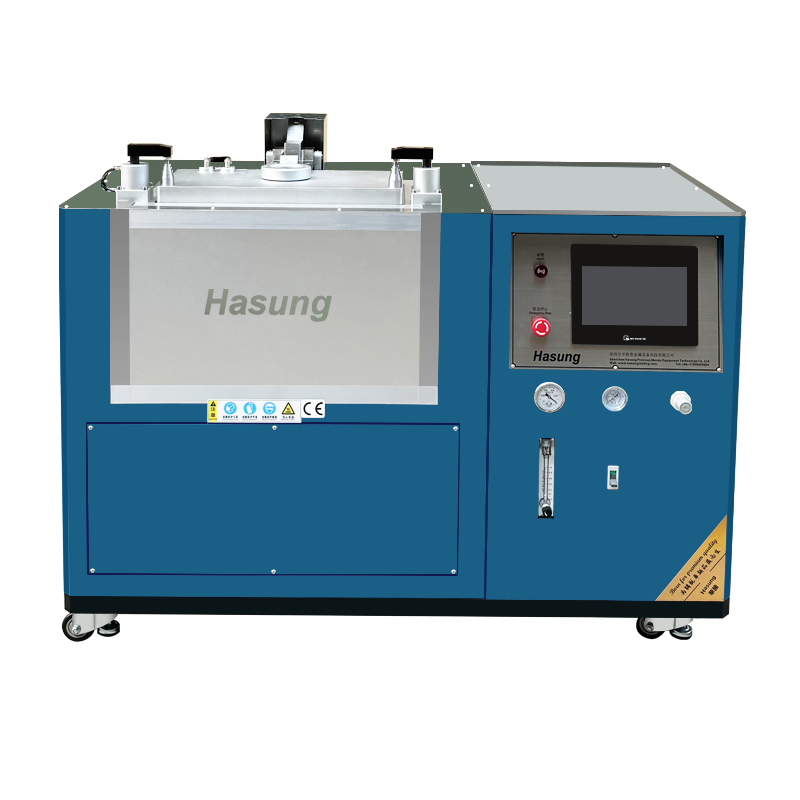

Gold and silver have been symbols of wealth, value preservation and luxury since ancient times. From ancient gold ingots to modern investment gold bars, people have never stopped pursuing them. But have you ever thought about the difference between the raw materials of a top-grade investment gold bar and ordinary gold jewelry? The answer lies in "purity" and "integrity". The key to achieving ultimate purity is a high-tech device called a "vacuum ingot casting machine". It is quietly innovating the production method of precious metals and casting a new generation of heirlooms.

1.Why does gold and silver casting also require a "vacuum" environment?

Traditional furnace casting seems straightforward, but it hides many problems. The vacuum environment has brought revolutionary improvements to gold and silver casting:

(1)Completely eliminate pores and shrinkage cavities

Traditional problem: Molten gold and silver will absorb a large amount of hydrogen and oxygen from the air. When the molten metal cools in the mold, these gases will precipitate, forming pores and bubbles that are visible to the naked eye or hidden inside. This not only affects the appearance, but also reduces the density and becomes a weak point in the structure. Vacuum solution: In a vacuum environment, the gas in the molten metal is effectively extracted, and the ingot becomes dense and uniform after cooling, eliminating any pores and ensuring the perfection of its physical structure.

(2) Achieve oxygen-free casting to eliminate oxidation and loss

Traditional problem: Silver is easily oxidized when melted in air, forming black silver oxide on the surface, resulting in loss and dull color. Even the most stable gold may react slightly with oxygen at high temperatures.

Vacuum solution: The vacuum environment deprives of oxygen, ensuring that the gold and silver are in an "ultra-clean" state throughout the entire process from melting to solidification. The surface of the ingot is as smooth as a mirror, and the dazzling luster of the metal itself can be displayed without complex processing. Silver ingots can especially show an unparalleled bright white texture.

(3) Ensure absolute accuracy and uniformity of composition

Traditional problem: When casting K gold or specific alloys (such as gold and silver coin alloys), the burning of certain easily oxidized elements (such as zinc and copper) will lead to composition deviation, affecting the color and hardness.

Vacuum solution: Vacuum melting precisely controls the volatilization of elements, ensuring that the fineness of each ingot is accurate, which is crucial for investment-grade precious metals, where the fineness must be strictly guaranteed.

(4) Provides unparalleled surface quality

Because there are no oxides or slag, the surface of vacuum-cast gold and silver ingots is extremely smooth, with clear textures and a significant "mirror effect". This greatly reduces the subsequent polishing and processing steps, and when directly imprinting patterns and text, the clarity and beauty are far superior to traditional ingots.

2. The Precision Process of Casting Gold and Silver Ingots Using a Vacuum Ingot Caster

The vacuum ingot casting machine creates a pristine "birthplace" tailored for precious metals:

Step 1: Careful Material Preparation

Qualified pure gold/silver raw materials or formulated alloys are placed in a water-cooled copper crucible (equivalent to a mold) within the furnace.

Step 2: Creating a Vacuum

Close the furnace door and start the vacuum pump to rapidly remove air from the furnace chamber, creating a nearly oxygen-free, pure atmosphere.

Step 3:Precision Melting

Start vacuum induction melting. High-frequency induction coils generate massive eddy currents within the metal, causing it to melt rapidly and evenly. The entire process is like heating with "invisible energy," eliminating any external contamination.

Step 4: Casting and Solidification

After melting is complete, the furnace can be tilted or the melt can be poured into a pre-prepared precision mold. Under the continuous vacuum, the melt cools steadily and solidifies directionally.

Step 5: Perfect Out of the Furnace

After cooling is complete, the furnace is filled with an inert gas (such as argon) to return to normal pressure. Open the furnace door, and a gold or silver ingot with a gleaming metallic luster and a dense, uniform structure is born.

3. The Value of Vacuum-Cast Gold and Silver Ingots: Who Needs Them?

Gold and silver ingots cast using this cutting-edge process serve sectors that demand the utmost in quality:

National mints and top refineries: Used as blanks for collectible gold and silver coins (such as Panda coins and Eagle Dollar coins), as well as high-standard investment gold and silver bars. Their flawless quality is a guarantee of credibility and value.

High-end jewelry and luxury brands: Used as raw material for fine jewelry and luxury watch cases and bracelets. Perfect ingots reduce processing defects and ensure the superior quality of the final product.

Financial institutions and high-net-worth investors: Vacuum-cast ingots represent the "top quality" of precious metals, offering higher fidelity and liquidity, making them a valuable asset in asset allocation.

Industrial and technological fields: Used in special scenarios that require high-purity, high-reliability gold and silver materials, such as semiconductor bonding wires, precision electronic contacts, etc.

4.Conclusion: Not just technology, but also commitment

The application of vacuum casting machines in the precious metals industry has long transcended mere technology. They represent an ultimate pursuit of purity, a solemn commitment to value, and a profound consideration for heritage.

When you hold a gold bar or silver coin produced using vacuum casting technology, you feel not only the weight of the precious metal but also the perfection and trust that modern technology has infused into this millennia-old treasure. It creates a foundation of confidence that will truly endure for generations to come.

You can contact us through the following ways:

Whatsapp: 008617898439424

Email: sales@hasungmachinery.com

Web: www.hasungmachinery.com www.hasungcasting.com

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115