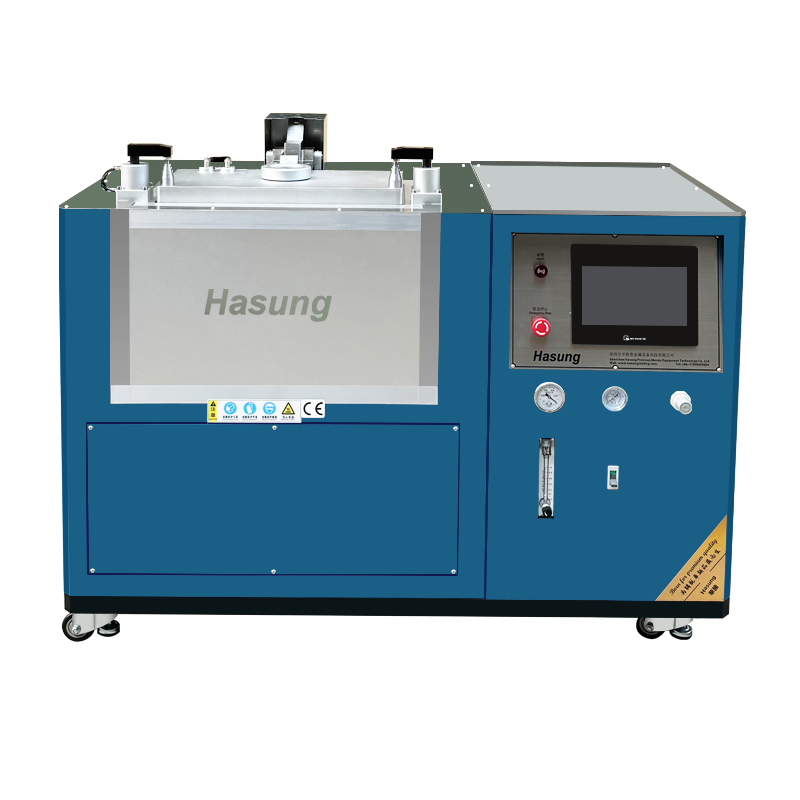

UHasung ungumkhiqizi womshini wokubumba nokuncibilikisa izinsimbi eziyigugu ochwepheshe kusukela ngo-2014.

Umshini wokuphonsa we-vacuum ingot uwakha kanjani ama-ingots egolide nesiliva “aphelele”?

Igolide nesiliva bekuyizimpawu zengcebo, ukulondolozwa kwenani kanye nokunethezeka kusukela ezikhathini zasendulo. Kusukela kuma-ingots egolide asendulo kuya emigoqweni yegolide yokutshalwa kwezimali yesimanje, abantu abakaze bayeke ukuwalandela. Kodwa uke wacabanga ngomehluko phakathi kwezinto ezingavuthiwe zebha yegolide yokutshalwa kwezimali yezinga eliphezulu nobucwebe begolide obujwayelekile? Impendulo ilele “kubumsulwa” kanye “nobuqotho”. Isihluthulelo sokuthola ubumsulwa obukhulu idivayisi yobuchwepheshe obuphezulu ebizwa ngokuthi " i-vacuum ingot casting machine ". Isungula buthule indlela yokukhiqiza yezinsimbi eziyigugu futhi isakaza isizukulwane esisha samafa.

1.Kungani ukubunjwa kwegolide nesiliva nakho kudinga indawo "ye-vacuum"?

Ukukhishwa kwesithando somlilo wendabuko kubonakala kuqondile, kodwa kufihla izinkinga eziningi. Imvelo ye-vacuum ilethe ukuthuthukiswa kokushintshashintsha kokusakazwa kwegolide nesiliva:

(1) Susa ngokuphelele ama-pores kanye nokushwabana kwemigodi

Inkinga yendabuko: Igolide nesiliva elincibilikisiwe kuzomunca inani elikhulu le-hydrogen nomoya-mpilo emoyeni. Lapho insimbi encibilikisiwe iphola esibunjeni, la magesi azoncipha, akhe izimbotshana namabhamuza abonakala ngeso lenyama noma afihlwe ngaphakathi. Lokhu akuthinti nje ukubonakala, kodwa futhi kunciphisa ukuminyana futhi kuba iphuzu elibuthakathaka esakhiweni. Isixazululo se-vacuum: Endaweni ye-vacuum, igesi ensimbi encibilikisiwe ikhishwa ngokuphumelelayo, futhi ingot iba minyene futhi ifane ngemva kokupholisa, isuse noma yiziphi izimbotshana futhi iqinisekise ukuphelela kwesakhiwo sayo somzimba.

(2) Finyelela ukusakaza okungenawo umoya-mpilo ukuze kuqedwe i-oxidation nokulahlekelwa

Inkinga evamile: Isiliva likhishwa kalula nge-oxid uma lincibilika emoyeni, lenze i-silver oxide emnyama ngaphezulu, okuholela ekulahlekeni kanye nombala obumnyama. Ngisho negolide elizinze kakhulu lingase lisabele kancane ngomoya-mpilo emazingeni okushisa aphezulu.

Isixazululo se-vacuum: Indawo yevacuum ivimbela umoya-mpilo, iqinisekisa ukuthi igolide nesiliva kusesimweni "esihlanzeke kakhulu" kuyo yonke inqubo kusukela ekuncibilikeni kuya ekuqineni. Ingaphezulu le-ingot libushelelezi njengesibuko, futhi ukukhazimula okukhazimulayo kwensimbi ngokwayo kungaboniswa ngaphandle kokucubungula okuyinkimbinkimbi. Ama-ingots esiliva angabonisa ikakhulukazi ukuthungwa okumhlophe okukhanyayo okungenakuqhathaniswa.

(3) Qinisekisa ukunemba okuphelele nokufana kokwakheka

Inkinga evamile: Uma usakaza igolide elingu-K noma ama-alloys athile (njengama-alloys ohlamvu lwegolide nesiliva), ukushiswa kwezinto ezithile ezenziwe nge-oxidized kalula (njengezinc nethusi) kuzoholela ekuphambukeni kokwakheka, okuthinta umbala nobulukhuni.

Isixazululo sevacuum: Ukuncibilika kwevacuum kulawula ngokunembile ukuguquguquka kwezakhi, kuqinisekisa ukuthi ukucoleka kwengot ngayinye kunembile, okubalulekile ezinsimbi eziyigugu zezinga lokutshala izimali, lapho ukucwiliswa kufanele kuqinisekiswe ngokuqinile.

(4) Ihlinzeka ngekhwalithi yendawo engenakuqhathaniswa

Ngenxa yokuthi awekho ama-oxides noma i-slag, ingaphezulu legolide nesiliva le-vacuum cast libushelelezi ngokwedlulele, linokwakheka okucacile kanye "nomphumela wesibuko". Lokhu kunciphisa kakhulu izinyathelo ezilandelayo zokupholisha nokucubungula, futhi lapho uphrinta ngokuqondile amaphethini nombhalo, ukucaca nobuhle kuphakeme kakhulu kune-ingots evamile.

2. Inqubo Enembayo Yokuphonsa Igolide Neziyingo Zesiliva Ngokusebenzisa I-Vacuum Ingot Caster

Umshini wokuphonsa we-vacuum ingot udala "indawo yokuzalwa" ehlanzekile eyenzelwe izinsimbi eziyigugu:

Isinyathelo 1: Ukulungiselela Izinto Ngokucophelela

Izinto ezisetshenziswayo ezihlanzekile zegolide/zesiliva noma ama-alloys akhiwe afakwa ku-crucible yethusi epholiswe ngamanzi (elingana nesikhunta) ngaphakathi kwesithando somlilo.

Isinyathelo sesi-2: Ukudala i-Vacuum

Vala umnyango wesithando somlilo bese uqala iphampu yevacuum ukuze ususe umoya ngokushesha egumbini lesithando somlilo, udale umoya ohlanzekile ongenawo umoya-mpilo.

Isinyathelo sesi-3: Ukuncibilika Ngokunemba

Qala ukuncibilika kwe-vacuum induction. Amakhoyili wokungeniswa kwe-high-frequency induction akhiqiza ama-eded currents amakhulu ngaphakathi kwensimbi, ayenze incibilike ngokushesha nangokulinganayo. Yonke le nqubo ifana nokufudumeza "ngamandla angabonakali," okuqeda noma yikuphi ukungcola kwangaphandle.

Isinyathelo sesi-4: Ukusakaza nokuqinisa

Ngemva kokuncibilika sekuqediwe, isithando somlilo singatshekiswa noma ukuncibilika kuthululelwe esikhunjini esilungisiwe esilungiselelwe kusengaphambili. Ngaphansi kwe-vacuum eqhubekayo, ukuncibilika kuphola kancane futhi kuqina ngendlela eqondile.

Isinyathelo sesi-5: Iphelele Ngaphandle Kwesithando

Ngemuva kokuthi ukupholisa kuqediwe, isithando somlilo sigcwaliswa ngegesi ye-inert (njenge-argon) ukuze ubuyele ekucindezelweni okuvamile. Vula umnyango wesithando somlilo, futhi ingot yegolide noma yesiliva enokukhanya kwensimbi ekhazimulayo kanye nokwakheka okuminyene, okufanayo kuyazalwa.

3. Inani le-Vacuum-Cast Gold kanye Nezinsimbi Zesiliva: Ubani Ozidingayo?

Ama-ingots egolide nesiliva asakazwa kusetshenziswa le nqubo esezingeni eliphezulu asebenzela imikhakha efuna okukhulu kakhulu ngekhwalithi:

Ama-mint kazwelonke nezindawo zokucolisiswa eziphezulu: Asetshenziswa njengezikhala zezinhlamvu zemali zegolide nesiliva eziqoqwayo (njengezinhlamvu zemali ze-Panda kanye nezinhlamvu ze-Eagle Dollar), kanye nezinga eliphezulu zokutshala imali zegolide nezesiliva. Izinga labo elingenasici liyisiqinisekiso sokwethembeka kanye nenani.

Ubucwebe bezinga eliphezulu nemikhiqizo ephambili: Isetshenziswa njengempahla eluhlaza yobucwebe obuhle namakesi wewashi aphambili namasongo. Ama-ingots aphelele anciphisa amaphutha okucubungula futhi aqinisekise ikhwalithi ephezulu yomkhiqizo wokugcina.

Izikhungo zezezimali nabatshalizimali abanenani eliphakeme: Ingothi ekhishwa ngevacuum imelela "ikhwalithi ephezulu" yezinsimbi eziyigugu, enikeza ukwethembeka okuphezulu kanye nenani lemali, okuwenza abe yimpahla ebalulekile ekwabiweni kwempahla.

Izinkambu zezimboni nezobuchwepheshe: Isetshenziswa ezimeni ezikhethekile ezidinga ukuhlanzeka okuphezulu, izinto ezithembeke kakhulu zegolide nezesiliva, njengezintambo zokubopha i-semiconductor, oxhumana nabo be-elekthronikhi abanembile, njll.

4. Isiphetho: Hhayi nje ubuchwepheshe, kodwa nokuzibophezela

Ukusetshenziswa kwemishini yokukhipha ivacuum embonini yensimbi eyigugu sekuyisikhathi eside kwedlula ubuchwepheshe nje. Bamele ukuphishekela ukuhlanzeka, ukuzibophezela okuqotho ekubaluleni, kanye nokucatshangelwa okujulile kwamagugu.

Uma ubambe ibha yegolide noma uhlamvu lwesiliva lwesiliva olukhiqizwa kusetshenziswa ubuchwepheshe be-vacuum casting, awuzwa nje kuphela isisindo sensimbi eyigugu kodwa futhi nokuphelela nokwethemba ubuchwepheshe besimanje obufake kulo mcebo weminyaka eyinkulungwane. Kwakha isisekelo sokuzethemba esiyohlala sikhona ngempela ezizukulwaneni ezizayo.

Ungaxhumana nathi ngezindlela ezilandelayo:

WhatsApp: 008617898439424

I-imeyili:sales@hasungmachinery.com

Iwebhusayithi: www.hasungmachinery.com www.hasungcasting.com

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjiniyela bemishini etholakala eningizimu yeShayina, edolobheni elihle nelikhula ngokushesha kwezomnotho, iShenzhen. Le nkampani ingumholi kwezobuchwepheshe emkhakheni wemishini yokushisa nokukhipha izinsimbi eziyigugu kanye nemboni yezinto ezintsha.

Ulwazi lwethu oluqinile kubuchwepheshe bokuphonswa kwe-vacuum lusenza sikwazi ukukhonza amakhasimende ezimboni ukuze afake insimbi exutshwe kakhulu, i-platinum-rhodium alloy edingekayo nge-vacuum ephezulu, igolide nesiliva, njll.

Ucingo: +86 17898439424

I-imeyili: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Ikheli: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115