Ingaba umatshini wokuphosa we-vacuum ingot udala njani "egqibeleleyo" iingots zegolide nezesilivere?

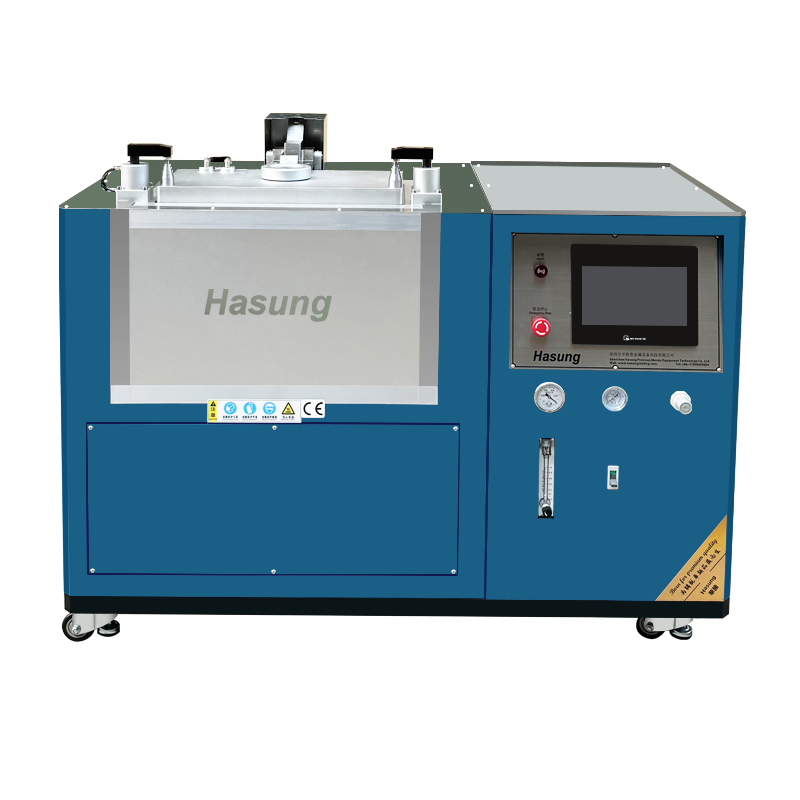

Igolide nesilivere ibingumqondiso wobutyebi, ukulondolozwa kwexabiso kunye nobunewunewu ukusukela kumaxesha amandulo. Ukusuka kwii-ingots zegolide zamandulo ukuya kwimivalo yegolide yotyalo-mali yanamhlanje, abantu abazange bayeke ukubasukela. Kodwa ngaba ukhe wacinga ngomahluko phakathi kwezinto ezikrwada zebhari yegolide yotyalo-mali oluphezulu kunye nobucwebe begolide obuqhelekileyo? Impendulo ilele "kubunyulu" kunye "nokunyaniseka". Isitshixo ekufezekiseni ubunyulu bokugqibela sisixhobo sobuchwepheshe obuphezulu esibizwa ngokuba yi " vacuum ingot casting machine ". Isungula ngokuzolileyo indlela yemveliso yeentsimbi ezixabisekileyo kwaye ikhuphe isizukulwana esitsha selifa.

1.Kutheni igolide kunye nesilivere ephosayo nayo ifuna indawo "yevacuum"?

Ukuphoswa kwesithando somlilo kubonakala kuthe ngqo, kodwa kufihla iingxaki ezininzi. Imo engqongileyo yevacuum izise uphuculo lwenguqu kwigolide kunye nesilivere yokuphosa:

(1) Zisuse ngokupheleleyo iipores kunye nokushwabana kwemingxuma

Ingxaki yemveli: Igolide etyhidiweyo kunye nesilivere iya kutsala isixa esikhulu sehydrogen kunye neoksijini emoyeni. Xa intsimbi etyhidiweyo iphola ekubumbeni, ezi gesi ziya kudlula, zenze iipores kunye namaqamza abonakala ngeso lenyama okanye afihlwe ngaphakathi. Oku akuchaphazeli nje ukubonakala, kodwa kunciphisa ukuxinana kwaye kuba yinto ebuthathaka kwisakhiwo. Isisombululo se-vacuum: Kwindawo yokucoca, igesi kwintsimbi etyhidiweyo ikhutshwe ngokufanelekileyo, kwaye i-ingot iba yinkimbinkimbi kwaye ifanayo emva kokupholisa, isusa nayiphi na i-pores kunye nokuqinisekisa ukugqibelela kwesakhiwo sayo somzimba.

(2) Ukufezekisa i-oxygen-free casting ukuphelisa i-oxidation kunye nelahleko

Ingxaki yesiNtu: Isilivere ifakwa ioksijini ngokulula xa inyibilika emoyeni, yenze i-oxide yesilivere emnyama kumphezulu, ikhokelela kwilahleko kunye nombala ongacacanga. Kwaneyona golide izinzile inokusabela kancinane ngeoksijini kumaqondo obushushu aphezulu.

Isisombululo sevacuum: Indawo evacuum ivimba ioksijini, iqinisekisa ukuba igolide nesilivere zikwimeko "ecocekileyo kakhulu" kuyo yonke le nkqubo ukusuka ekunyibilikeni ukuya ekuqinisweni. Ubuso be-ingot bubushelelezi njengesibuko, kwaye ukukhanya okukhazimulayo kwesinyithi ngokwawo kunokubonakaliswa ngaphandle kokucubungula okunzima. Ii-ingots zesilivere zinokubonisa ngokukodwa ukuthungwa okumhlophe okuqaqambileyo okungenakulinganiswa.

(3) Qinisekisa ukuchaneka ngokupheleleyo kunye nokufana kokuqulunqwa

Ingxaki yesiNtu: Xa kusenziwa i-K yegolide okanye ialloys ezithile (ezifana ne-alloys yengqekembe yegolide neyesilivere), ukutshiswa kwezinto ezithile ezixutywe lula (ezifana nezinc kunye nobhedu) kuya kukhokelela ekuphambukeni kokwakheka, okuchaphazela umbala kunye nobulukhuni.

Isisombululo sevacuum: Ukunyibilika kwevacuum kulawula ngokuchanekileyo ukuguquguquka kwezinto, kuqinisekisa ukuba ukucoleka kwengot nganye kuchanekile, okubalulekileyo kudidi lotyalo-mali lwesinyithi esixabisekileyo, apho ukucolwa kufuneka kuqinisekiswe ngokungqongqo.

(4) Ibonelela ngomgangatho womgangatho ongenakulinganiswa

Ngenxa yokuba akukho oksidi okanye i-slag, umphezulu we-vacuum-cast yegolide kunye nesilivere ye-ingots igudile kakhulu, inokwakheka okucacileyo kunye "nempembelelo yesibuko". Oku kunciphisa kakhulu amanyathelo alandelayo okupolisha kunye nokucubungula, kwaye xa uprinta ngokuthe ngqo iipateni kunye nesicatshulwa, ukucaca kunye nobuhle buphezulu kakhulu kuneengots zendabuko.

2. Inkqubo echanekileyo yokuphosa iGolide kunye neSilver Ingots usebenzisa iVacuum Ingot Caster.

Umatshini wokuphosa we-vacuum ingot wenza "indawo yokuzalwa" ecocekileyo eyenzelwe iintsimbi ezixabisekileyo:

Inyathelo 1: Ukulungiselela Ngononophelo Izinto

Igolide ecocekileyo / izixhobo zesilivere ezisemgangathweni okanye i-alloys eyenziweyo ifakwe kwi-crucible yobhedu epholile ngamanzi (elingana nokubumba) ngaphakathi kwesithando somlilo.

Inyathelo lesi-2: Ukudala iVacuum

Vala ucango lwesithando somlilo kwaye uqalise impompo yokucoca ukususa ngokukhawuleza umoya kwigumbi lesithando somlilo, udale umoya ophantse ungabi na-oksijini, umoya ococekileyo.

Inyathelo lesi-3: Ukunyibilika okuchanekileyo

Qala ukunyibilika kwe-vacuum induction. Iikhoyili ze-high-frequency induction coil zivelisa imisinga enkulu yeeddy ngaphakathi kwentsimbi, ibangela ukuba inyibilike ngokukhawuleza nangokulinganayo. Yonke le nkqubo ifana nokufudumeza "ngamandla angabonakaliyo," ukuphelisa naluphi na ungcoliseko lwangaphandle.

Inyathelo 4: Ukuphosa kunye nokuqinisa

Emva kokunyibilika kugqityiwe, isithando somlilo sinokuthambeka okanye ukunyibilika kungagalelwa kwi-mold echanekileyo elungiselelwe kwangaphambili. Ngaphantsi kwe-vacuum eqhubekayo, ukunyibilika kuphola ngokukhawuleza kwaye kuqiniswe kwicala.

Inyathelo lesi-5: Igqibelele ngaphandle kwesithando somlilo

Emva kokuba ukupholisa kugqityiwe, isithando somlilo sizaliswe ngegesi ye-inert (efana ne-argon) ukubuyela kuxinzelelo oluqhelekileyo. Vula umnyango wesithando somlilo, kunye negolide okanye i-ingot yesilivere enentsimbi ekhanyayo kunye ne-dense, isakhiwo esifanayo siyazalwa.

3. Ixabiso leGolide eVacuum-Cast kunye neSilver Ingots: Ngubani ozifunayo?

Igolide kunye nesilivere ingots eziphoswe kusetyenziswa le nkqubo yokusika ikhonza amacandelo afuna okona mgangatho uphezulu:

Iiminti zeSizwe kunye neendawo zokucokisa eziphezulu: Zisetyenziswa njengezinto ezingenanto kwingqekembe yegolide nesilivere eqokelelekayo (ezifana neengqekembe zePanda kunye neengqekembe ze-Eagle Dollar), kunye notyalo-mali olukumgangatho ophezulu wegolide neebhari zesilivere. Umgangatho wabo ongenasiphako sisiqinisekiso sokuthembeka kunye nexabiso.

Ubucwebe obukumgangatho ophezulu kunye neempawu zodidi oluphezulu: Isetyenziswa njengemathiriyeli ekrwada yobucwebe obucokisekileyo kunye neekesi zokubukela ezitofotofo kunye nezacholo. Iingots ezigqibeleleyo zinciphisa iziphene zokucubungula kwaye ziqinisekise umgangatho ophezulu wemveliso yokugqibela.

Amaziko emali kunye nabatyali-mali abanexabiso eliphezulu: Ii-ingots ze-vacuum-cast zimela "umgangatho ophezulu" weentsimbi ezixabisekileyo, ezinikezela ngokuthembeka okuphezulu kunye nokungabi namali, okubenza babe yi-asethi yexabiso kulwabiwo lwe-asethi.

Imimandla yoshishino neteknoloji: Isetyenziswa kwiimeko ezikhethekileyo ezifuna ukucoceka okuphezulu, ukuthembeka okuphezulu kwezinto zegolide kunye nesilivere, ezifana neengcingo ze-semiconductor bonding, uqhagamshelwano oluchanekileyo lwe-elektroniki, njl.

4.Isiphelo: Hayi nje iteknoloji, kodwa nokuzibophelela

Ukusetyenziswa koomatshini bokukhupha i-vacuum kwishishini leentsimbi ezixabisekileyo kudala kudlula itekhnoloji nje. Bamele usukelo lokugqibela lobunyulu, ukuzibophelela ngokundilisekileyo kwixabiso, kunye noqwalaselo olunzulu lwelifa lemveli.

Xa ubambe ibha yegolide okanye ingqekembe yesilivere eveliswa kusetyenziswa itekhnoloji yokuphosa ivacuum, awuziva nje ubunzima bentsimbi exabisekileyo kodwa kunye nokugqibelela kunye nokuthemba ukuba ubuchwepheshe bale mihla bufake kobu butyebi beminyaka eyiwaka. Idala isiseko sentembelo eya kuhlala ihleli kwizizukulwana ngezizukulwana.

Ungaqhagamshelana nathi ngezi ndlela zilandelayo:

Whatsapp: 008617898439424

I-imeyile:sales@hasungmachinery.com

IWebhu: www.hasungmachinery.com www.hasungcasting.com

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjineli boomatshini ekwimazantsi eTshayina, kwisixeko esihle nesikhula ngokukhawuleza kwezoqoqosho, iShenzhen. Le nkampani yinkokheli kwezobuchwepheshe kwicandelo lezixhobo zokufudumeza nokuthunga izixhobo zesinyithi esixabisekileyo kunye neshishini lezinto ezintsha.

Ulwazi lwethu olomeleleyo kubuchwepheshe bokuphosa i-vacuum lusenza sikwazi ukunceda abathengi bemizi-mveliso ukuphosa intsimbi exutywe kakhulu, i-platinum-rhodium alloy efunekayo kakhulu, igolide nesilivere, njl.

Umnxeba: +86 17898439424

I-imeyile:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Idilesi: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115