Hasung inyanzvi yekugadzira michina yekukanda nekunyungudutsa simbi dzinokosha kubvira muna 2014.

Chii Chinonzi Nheyo yeInduction Melting Machine?

Mazuvano, makambani akachinja zvachose magadzirirwo esimbi nekuda kwemashini ekunyungudusa emukati anopa ongororo chaiyo uye inoshanda yekunyungudusa nekunatsa simbi. Michina iyi inoita basa mumaindasitiri anosanganisira kugadzira simbi, kukanda maindasitiri, uye kugadzira zvishongo. Induction kunyunguduka mavira anowedzera simba remagetsi magineti kubata simbi dzakasiyana siyana, kubva kumaindasitiri-giredhi alloys kuenda kune sirivheri negoridhe, zviri nyore. Kuchinja kwavo uye kukosha kwakakosha mumunda wesimbi kunogona kuonekwa nekushandiswa kwavo, izvo zvinotangira kubva pakusikwa kwezvishongo zvakaoma kusvika kune yakawanda foundry mabasa.

Iyo Sainzi Kuseri kweInduction Heating

Pfungwa ye electromagnetic induction, iyo Michael Faraday akawana muzana ramakore rechi 19, ndiyo pfungwa yakakosha yekunyungudika induction. Simba remagineti rakasiyana rinokura kana alternating current (AC) inopfuura nepacoiled conductor. Eddy minda iri kutenderedza magetsi emagetsi anokura sezvo iyi magineti inopindirana nemashoko ekuitisa akakosha, simbi yakadai inoiswa mukati mecoil. The Joule effect ndiyo nzira iyo magetsi aya emagetsi anokonzera kupisa semugumisiro wekugadzirisa kwemagetsi kwesimbi.

Induction heat inoburitsa kupisa nekukasira mukati mesimbi, izvo zvinoita kuti ishande zvakanyanya kupfuura tsika dzechinyakare dzekudziya dzinoenderana nekupisa kwekunze. Izvi zvinoita kuti ive yakakwana yekunyungudutsa simbi ine simba shoma shoma sezvo ichivimbisa kukurumidza uye kunyangwe kudziyisa. Pamusoro pezvo, njodzi dzekusvibiswa dzakadzikiswa nekuda kwekushaikwa kwekukurumidza kusangana pakati pesimbi neinodziya sosi, kuve nechokwadi chepristine mamiriro ezvinhu akanyungudutswa.

Core Zvikamu zveInduction Melting Machines

Zvimwe zvakasiyana zvakakosha zvinogadzira michina yekunyungudutsa induction, asi imwe neimwe yakakosha pakunyungudika:

● Induction Coil: Chikamu chikuru chekugadzira magnetic field ndeye induction coil, iyo inowanzove ine mhangura inopiwa kushamisa kwayo kwemagetsi. Nechinangwa chekuva nechokwadi chekufambiswa kwekushisa kwakanaka, chimiro checoil uye marongerwo anogadziridzwa kuti akwane hukuru hwakasiyana hwesimbi uye mafomu.

● Power Supply System: Ikozvino inoshandura inodiwa kuti electromagnetic induction inopiwa nemagetsi. Nechinangwa chekugadzirisa iyo induction process yeakasiyana simbi uye mashandisirwo, anomhanyisa anoshandura anowanzo kushandiswa kugadzirisa frequency yeazvino.

● Crucibles: Munguva yose yekunyunguduka, simbi yakanyunguduka inochengetwa mumakumbo. Iwo akagadzirwa kubva kumidziyo yakaita seceramic kana graphite inoenderana nesimbi inonyungudutswa kuitira kuti ikwanise kumira kutonhora kwakanyanya uye kudzivirira kuita kwemakemikari.

● Kutonhodza Systems: Nokuti induction kunyunguduka kunounza kupisa kwakawanda, kushanda kwakavimbika kunoda kutonhora kwakasimba. Maitiro ekutsinhanisa kupisa uye mvura yakanyoroveswa coils inowanzoshandiswa kuparadzira kupisa kwakanyanya uye kuwedzera hupenyu hwemidziyo.

Kushanda Nheyo

Tsanangudzo yakazara yemabatiro anoita muto wekunyungudika induction inogona kupihwa pano:

▶ Metal Kuiswa: Mukati meiyo induction coil, zvinhu zvinoda kunyungudutswa zvinoiswa mucrucible.

▶ Mashandisirwo eMasimba: Iyo inochinjika ikozvino inogadzirwa nemasimba emagetsi inopfuura nepainduction coil kuti ibudise inochinja-chinja magineti.

▶ Eddy Current Induction: Nekugadzira kupikisa kwemagetsi, iyo magineti inokonzera mafambiro anonzi eddy currents kuti ayerere musimbi yese, achigadzira kupisa.

▶ Melting process: Simbi inoshanduka kunyunguduka semhedzisiro yekupisa inogadzirwa ichikwidza tembiricha yayo kusvika pakunyungudika kwayo.

▶ Kudzora Tembiricha: Kuvimbisa kurongeka uye kudzivirira kupisa zvakanyanya, masensa akanyanya kuoma uye masisitimu emakombuta anogara achiteedzera uye kugadzirisa tembiricha.

Nezvese kuwanda uye kusimba kwesimba remagineti rakagadziridzwa kuti rikwane chinhu chaicho chiri kurapwa, nzira iyi inoshanda nemazvo pazvose zviri zviviri ferrous uye zvisiri-ferrous simbi. Kugadzirisa nzira yekunyunguduka kunovimbisa mhedzisiro yakafanana, kunowedzera kubereka, uye kunoderedza kukanganisa kwevanhu.

Zvakanakira zveInduction Melting Machines

Kuenzaniswa nemaitiro echinyakare ekunyunguduka, induction casting michina ine akawanda mabhenefiti.

◆ Energy Efficiency: Induction melting inodarika mafuta-based furnaces yakapiwa kuti inoshandisa magetsi emagetsi kuti ibudise kupisa pakarepo mukati mesimbi. Yayo yakatarisana yekudziya sisitimu inobvisa zvakanyanya kutambisa simba, ichipa yakasarudzika yekupisa kunyatsoshanda. Pamusoro pezvo, maitiro akabviswa anoderedza kushandiswa kwemagetsi, zvichiita kuti ive isingadhure uye ine hushamwari hwezvakatipoteredza kune iripo maindasitiri ekushandisa.

◆ Accrate Temperature Control: Tekinoroji yemazuva ano ye otomatiki muzvivakwa zvemazuva ano inopa vashandisi kunyatso kudzora tembiricha & chaiyo-nguva yekutarisa. Iyi nhanho yehutsanana haingovimbisi chete iyo yakanyanya kunyungudika mamiriro, asi zvakare inovandudza metallurgical features, zvichikonzera mhedzisiro inogara yakamira. Kuve nekukwanisa kunyatsogadzirisa marongero etembiricha kunoderedza kusawirirana kwezvinhu uku uchiwedzera kunaka kwechigadzirwa.

◆ Environmental Benefits: Induction kunyunguduka chinhu chakakosha chekusimudzira kune zvakatipoteredza inoziva maindasitiri maitiro. Zvisinei nemavira akajairika, anopedza mafuta ezvicherwa uye anoburitsa magasi ane njodzi, nzira iyi yekushandisa haibudisi utsi hune chepfu, ichidzikisa zvakanyanya kabhoni yayo. Pamusoro pezvo, kushaikwa kwehutsi hune chekuita nekupisa hunoenderana nezvinangwa zvekusimudzira pasi rose, zvichiita kuti ive chikamu chakakosha chemaitiro ekugadzira girini.

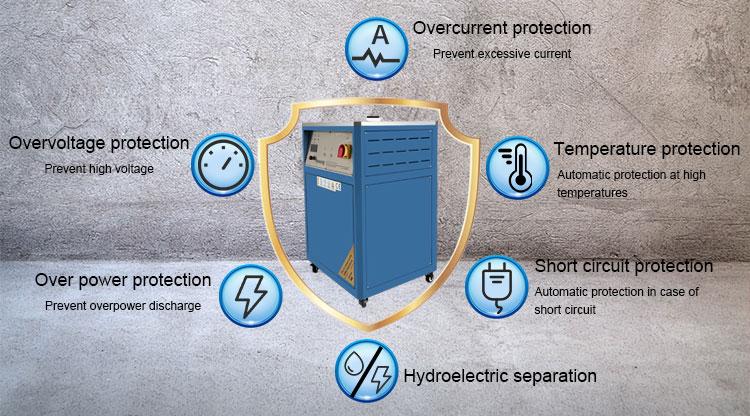

◆ Kuchengeteka uye kushambidzika: Kusavapo kwehuni nemirazvo yakafumurwa inoderedza zvakanyanya kutyisidzira kwemoto, zvichiita kuti pave nemamiriro ekushanda akachengeteka. Zvakare, induction masisitimu anoshanda ane kashoma ruzha uye chidimbu chinhu, chinotungamira kune yakachena uye ine hutano nzvimbo yebasa. Izvo hazvingochengetedze vashandi chete, asi zvakare zvinowedzera kushanda zvakanaka nekudzikisa mukana wetsaona kana kusvibiswa.

Zvishandiso zveInduction Melting Technology

Nekuda kwekusiyana-siyana kwayo, induction kunyunguduka nzira yakakura kushandiswa zvakanyanya mumaindasitiri mazhinji akasiyana:

● Jewelry Indasitiri: Pakugadzirwa kwemaitiro akaomarara uye alloys akachena, induction kunyunguduka kunowanzoshandiswa kunyungudutsa simbi dzakakosha segoridhe, sirivha, kunyange platinum.

● Zvishandiso muIndasitiri: Iyo nzira inoshandiswa kunyungudutsa-yakachena-alloys nesimbi inoshandiswa mumagetsi, emotokari, uye aerospace sectors.

● Foundry Operations: Kuti tive nechokwadi chekufanana uye kunyatsoita mukugadzirwa kwesimbi yakakura, induction simbi yekunyunguduka yakakosha pakukanda nekugadzirisa mabasa.

Kuenzanisa neMaitiro Echinyakare Melting Techniques

Kuenzaniswa neyakajairwa mafuta-based kunyunguduka nzira, induction yekunyungudutsa michina inopa akawanda mabhenefiti.

■ Kunyatsogona: Kunyunguduka kunoderedza mari yekushandisa nekuti inokurumidza uye inoshandisa simba shoma.

■ Kukanganisa Kwezvakatipoteredza: Kunyunguduka kwemukati iimwe nzira inogadzika kupfuura mavira echinyakare anoshandisa mafuta emafuta uye anoburitsa kabhoni yakawanda.

■ Kurongeka: Zvinogona kunetsa kuwana mhando yemhando yepamusoro uye kuenderana nemaitiro echinyakare, asi kuve nekwaniso yekudzora tembiricha nemazvo kunovimbisa zvese.

Technological Innovations uye Trends

Iko kugona kwemakina ekukanda ma induction kwakakwidziridzwa zvakanyanya kuburikidza nezvichangobva kuitika:

● Zvirinani Coil Dhizaini: Kunatsiridzwa kwemakoiri magadzirirwo uye zvinhu zvakawedzera kushanda zvakanaka pakushandisa simba shoma.

● Automation Integration: Munguva chaiyo yekutarisa, yakarongwa kuchengetedza, uye optimization yekufamba kwebasa zvinopihwa zvinogoneka neakangwara otomatiki masisitimu uye Internet yeZvinhu kubatanidzwa.

● Green Manufacturing: Indasitiri yemetallurgy iri kushandisa nzira dzinoenderana nemhoteredzo nekuda kwekufambira mberi kwezvinhu zvinochengetedza zvakatipoteredza uye ruzivo rwekuchengetedza simba.

Aya magadzirirwo anoratidza kuzvipira kweindasitiri mukusimudzira goho, kudzikisira kukanganiswa kwezvakatipoteredza, nekupa zvinodiwa zvekugadzirwa kwemazuva ano.

Mhedziso

Chinhu chakakosha chemazuva ano kugadzira simbi, induction kunyunguduka mavira anopa nzira chaiyo, inoshanda, uye yezvakatipoteredza yekunyungudutsa nekuchenesa simbi. Zvishandiso izvi zvakashandura zvikamu zvakasiyana-siyana, kubva pakuwanda kwemabasa ekutanga kusvika pakugadzira zvishongo, kuburikidza nekushandisa misimboti yemagetsi. Michina yekunyungudutsa induction inotarisirwa kuve nemhedzisiro yakakura pagwara rekushanda uye kushamwaridzana kwesimbi kugadziridzwa mumakore anouya sezvo hunyanzvi hwekuvandudza mashandiro avo uye dhizaini. Tsvaga ruzivo nezve induction inonyungudika choto paHasung!

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ikambani yeinjiniya yemakanika iri kumaodzanyemba kweChina, muguta rakanaka uye riri kukura nekukurumidza muhupfumi, Shenzhen. Kambani iyi inotungamira muhunyanzvi hwetekinoroji munharaunda yemidziyo yekudziyisa nekukanda simbi dzinokosha neindasitiri yezvinhu zvitsva.

Ruzivo rwedu rwakasimba muhunyanzvi hwekukanda vacuum runotigonesawo kushandira vatengi vemaindasitiri kugadzira simbi ine musanganiswa wakawanda, platinum-rhodium alloy inodiwa ne musanganiswa wakawanda, goridhe nesirivha, nezvimwewo.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Kero: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115