UHasung ungumkhiqizi womshini wokubumba nokuncibilikisa izinsimbi eziyigugu ochwepheshe kusukela ngo-2014.

Uyini Umgomo Womshini Wokuncibilikisa Wokungeniswa?

Kulezi zinsuku, izinkampani sezishintshe ngokuphelele ukuthi izinsimbi zicutshungulwa kanjani ngenxa yemishini yokuncibilika yokungeniswa ehlinzeka ngokuhlolwa okunembe nangempumelelo ukuze kuncibilike futhi kucwengisiswe izinsimbi. Le mishini ibamba iqhaza ezimbonini ezihlanganisa ukwenziwa kwensimbi, ukulingisa ezimbonini, kanye nokukhiqizwa kobucwebe. Iziko lokuncibilika lokungeniswa kwe-induction lisebenzisa izimiso ezinamandla kazibuthe ukuze zibambe izinhlobonhlobo eziningi zezinsimbi, kusukela kuma-alloys ebanga lezimboni kuya esiliva negolide, kalula. Ukuzivumelanisa nezimo nokubaluleka okubalulekile emkhakheni wokusebenza kwensimbi kungabonakala ngokusetshenziswa kwazo, okusukela ekudalweni kobucwebe obuyinkimbinkimbi kuya ekusebenzeni okubanzi kwe-Foundry.

Isayensi Engemuva Kokushisa Okungeniswayo

Umqondo wokungeniswa kwe-electromagnetic, owatholwa nguMichael Faraday ngekhulu le-19, uwumqondo oyisisekelo wokuncibilika kokungeniswa. Inkambu kazibuthe eguquguqukayo ikhula lapho i-alternating current (AC) idlula ku-conductor eboshiwe. Izinkambu ze-Eddy zizungeza amaza kagesi athuthukayo njengoba le nkundla kazibuthe ihlangana namagama ayisisekelo e-conductive, insimbi enjalo efakwa ngaphakathi kwekhoyili. Umthelela we-Joule inqubo lapho la maza kagesi abangela ukushisa njengomphumela wokuvinjwa kukagesi kwensimbi.

Ukushisa kwe-induction kukhiqiza ukushisa ngokushesha ngaphakathi kwensimbi, okuyenza iphumelele kakhulu kunezindlela zokushisisa zendabuko ezincike emithonjeni yokushisa yangaphandle. Lokhu kuyenza ifaneleke ekuncibilikiseni izinsimbi ngokumosha amandla okuncane njengoba iqinisekisa ukufudumeza okusheshayo ngisho nokushiswa. Ngaphezu kwalokho, izingozi zokungcola ziye zancishiswa ngenxa yokuntuleka kokuxhumana okusheshayo phakathi kwensimbi nomthombo wokushisa, okuqinisekisa isimo esihlanzekile sezinto ezincibilikisiwe.

Izingxenye Eziyinhloko Zemishini Yokuncibilikisa Yokungeniswa

Izingxenye ezibalulekile ezahlukahlukene ezakha imishini yokuncibilikisa yokungeniswa, kodwa ngayinye ibalulekile enqubweni yokuncibilika:

● Ikhoyili Yokungeniswa: Ingxenye eyinhloko ephethe ukukhiqiza amandla kazibuthe ikhoyili yokungeniswa, ngokuvamile ehlanganisa ithusi uma kubhekwa ukuqhutshwa kwayo okuphawulekayo kukagesi. Ngenhloso yokuqinisekisa ukudluliswa kokushisa okuphumelelayo, uhlaka lwekhoyili kanye nesakhiwo kuyalungiswa ukuze kulingane osayizi bensimbi namafomu ahlukahlukene.

● Isistimu Yokunikezela Ngamandla: Isimanje esishintshayo esidingekayo ukuze kufakwe ugesi kagesi sinikezwa amandla kagesi. Ngenhloso yokuthuthukisa inqubo yokungeniswa kwezinsimbi ezahlukene nezinhlelo zokusebenza, iziguquli zesivinini zivame ukusetshenziswa ukuze kulungiswe imvamisa yamanje.

● Ama-crucibles: Kuyo yonke inqubo yokuncibilika, insimbi encibilikisiwe igcinwa ezitsheni. Zenziwe ngezinto ezifana ne-ceramic noma i-graphite ehambisana nensimbi encibilikisiwe ukuze imelane namazinga okushisa aphezulu futhi ivimbele ukusabela kwamakhemikhali.

● Amasistimu Okupholisa: Ngenxa yokuthi ukuncibilika kokungeniswa kukhiqiza ukushisa okuningi, ukusebenza okuthembekile kudinga amasistimu okupholisa aqinile. Amasistimu okushintshanisa ukushisa namakhoyili apholile amanzi avame ukusetshenziselwa ukuhlakaza ukushisa okudlulele futhi andise impilo yezinto zokusebenza.

Isimiso Sokusebenza

Incazelo ebanzi yokuthi isithando somlilo sokuncibilika sisebenza kanjani singanikezwa lapha:

▶ Ukubekwa Kwensimbi: Ngaphakathi kwekhoyili yokungeniswa, impahla edinga ukuncibilika ifakwa ku-crucible.

▶ Isicelo samandla: Intambo yamandla eshintshanayo ekhiqizwa imithombo yamandla idlula ikhoyili yokungeniswa ukuze ikhiqize indawo kazibuthe eshintshayo.

▶ I-Eddy Current Induction: Ngokukhiqiza ukumelana nogesi, inkambu kazibuthe ibangela imisinga ebizwa ngokuthi ama-eddy currents ukuthi igeleze kuyo yonke insimbi, ikhiqize ukushisa.

▶ Inqubo Yokuncibilika: Insimbi iphenduka inyibilike njengomphumela wokushisa okukhiqizwayo kukhuphula izinga lokushisa layo lifinyelele lapho lincibilika khona.

▶ Ukulawula Ukushisa: Ukuqinisekisa ukunemba nokugwema ukushisa ngokweqile, izinzwa eziyinkimbinkimbi kakhulu namasistimu ekhompuyutha ahlala elandelela futhi elawula izinga lokushisa.

Ngokulungiswa kobuningi namandla kazibuthe ukuze kulingane into ethile ephathwayo, le ndlela isebenza kahle kuzo zombili izinsimbi eziyinsimbi nezingezona ayoni. Ukwenza lula inqubo yokuncibilika kuqinisekisa imiphumela efanayo, kwandisa ukukhiqiza, futhi kunciphisa amaphutha abantu.

Izinzuzo Zemishini Yokuncibilikisa Yokungeniswa

Uma kuqhathaniswa nezindlela zendabuko zokuncibilika, imishini yokukhipha induction inezinzuzo eziningi.

◆ Ukusebenza Kwamandla Kahle: Ukuncibilika kwe-induction kudlula iziko elisekelwe kuphethiloli uma kubhekwa ukuthi kusebenzisa izinkambu zikazibuthe ukukhiqiza ukushisa khona manjalo ngaphakathi kwensimbi. Isistimu yayo yokushisa egxilile iqeda kakhulu ukuchithwa kwamandla, ihlinzeka ngokusebenza kahle kokushisa okungavamile. Ngaphezu kwalokho, inqubo esusiwe inciphisa ukusetshenziswa kwamandla, ikwenze kube enye indlela engabizi futhi evumelana nemvelo kunezinhlelo ezikhona zezimboni.

◆ Ukulawula Izinga lokushisa Okunembile: Ubuchwepheshe besimanje bokuzenzakalela ezakhiweni zesimanje bunikeza opharetha ukulawulwa kwezinga lokushisa okunembe ngokwedlulele nokuqapha ngesikhathi sangempela. Leli zinga lokunemba aliqinisekisi kuphela izimo ezingcono kakhulu zokuncibilika, kodwa futhi lithuthukisa izici ze-metallurgical, okuholela emiphumeleni ehlala njalo evelele. Ukuba namandla okulungisa ngokunembile izilungiselelo zezinga lokushisa kunciphisa ukungahambisani kwezinto ngenkathi kuthuthukisa ikhwalithi yomkhiqizo iyonke.

◆ Izinzuzo Zemvelo: Ukuncibilika kokungeniswa kuyintuthuko ebalulekile emayelana nezinqubo zezimboni eziqaphela imvelo. Naphezu kwezithando zomlilo ezivamile, ezidla izinto zokubasa ezimbiwa phansi futhi zikhiphe amagesi ayingozi, le ndlela yokusebenza ayikhiphi intuthu enobuthi, eyehlisa kakhulu izinga layo lekhabhoni. Ngaphezu kwalokho, ukuntuleka kwezinto ezikhishwayo ezihlobene nokusha kuhambisana nezinjongo zokusimama komhlaba wonke, okwenza kube yingxenye ebalulekile yezinqubo zokukhiqiza eziluhlaza.

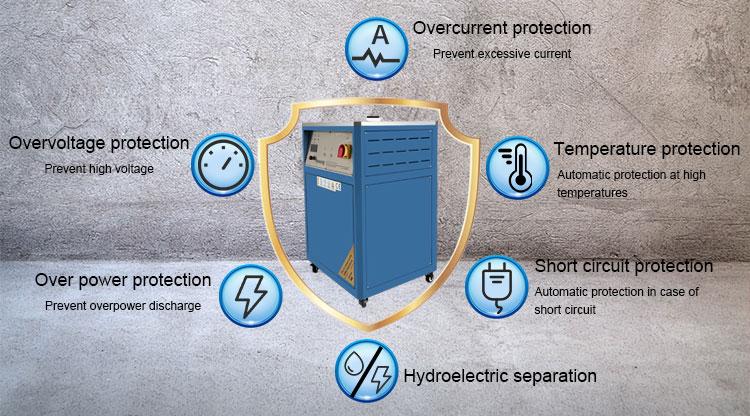

◆ Ukuphepha nokuhlanzeka: Ukungabikho kukaphethiloli namalangabi avele obala kunciphisa kakhulu izinsongo zomlilo, okuholela endaweni yokusebenza ephephile. Futhi, amasistimu wokungeniswa asebenza ngomsindo omncane kanye nezinhlayiyana, okuholela endaweni yokusebenza ehlanzekile nenempilo. Lokho akugcini nje ngokuvikela abasebenzi, kodwa futhi kuthuthukisa ukusebenza kahle ngokunciphisa amathuba ezingozi noma ukungcola.

Izicelo ze-Induction Melting Technology

Ngenxa yokuguquguquka kwayo, indlela yokuncibilikisa induction isikhule kakhulu ezimbonini eziningi ezahlukene:

● Imboni yobucwebe: Ukuze kukhiqizwe amaphethini ayinkimbinkimbi kanye nama-alloys ahlanzekile, ukuncibilika kwe-induction kuvame ukusetshenziselwa ukuncibilikisa izinsimbi ezibalulekile njengegolide, isiliva, ngisho neplatinamu.

● Izicelo Embonini: Indlela isetshenziselwa ukuncibilikisa ama-alloy nezinsimbi ezisetshenziswa emkhakheni wezogesi, wezimoto, kanye ne-aerospace.

● I-Foundry Operations: Ukuqinisekisa ukufana nokunemba ekukhiqizweni kwensimbi okukhulu, iziko elincibilikisayo elingeniswayo libalulekile emsebenzini wokulingisa nowokulungisa.

Ukuqhathanisa Nezindlela Zomdabu Zokuncibilika

Uma kuqhathaniswa nezindlela ezijwayelekile zokuncibilikisa ezisekelwe kuphethiloli, imishini yokuncibilikisa induction induction inikeza izinzuzo eziningi.

■ Ukusebenza kahle: Ukuncibilika kwe-induction kunciphisa izindleko zokusebenza ngoba kuyashesha futhi kusebenzisa amandla amancane.

■ Umthelela Wendawo Ezungezile: Ukuncibilika kokungeniswa kungenye indlela esimeme kakhulu kuneziko elivamile ezisebenzisa izinto zokubasa ezimbiwa phansi futhi zikhiqize ukukhishwa kwekhabhoni ephezulu.

■ Ukunemba: Kungaba inselele ukuthola ikhwalithi ephezulu nokuvumelana nezindlela ezivamile, kodwa ukuba namandla okulawula amazinga okushisa ngokunembile kuqinisekisa kokubili.

Ukuqanjwa Kwezobuchwepheshe kanye Nezitayela

Amakhono emishini yokufaka induction athuthukiswe kakhulu ngentuthuko yakamuva:

● Imiklamo Engcono Yekhoyili: Ukuthuthukiswa kwemiklamo yamakhoyili nezinto zokwakha kuthuthukise ukusebenza kahle kuyilapho kusetshenziswa amandla amancane.

● Ukuhlanganiswa Okuzenzakalelayo: Ukuqapha ngesikhathi sangempela, ukugcinwa okuhleliwe, nokuthuthukiswa kokugeleza komsebenzi kwenziwa ngendlela engenzeka amasistimu e-automation ahlakaniphile kanye nokuhlanganiswa kwe-inthanethi Yezinto.

● I-Green Manufacturing: Imboni ye-metallurgy isebenzisa amasu angavumelani nemvelo ngenxa yenqubekela phambili ezintweni eziphathelene nemvelo kanye nobuchwepheshe bokonga ugesi.

Lezi zindlela ezintsha zigqamisa ukuzinikela kwemboni ekukhuliseni umkhiqizo, ukunciphisa umthelela omubi endaweni ezungezile, nokuhlinzeka ngezidingo zokukhiqiza kwesimanje.

Isiphetho

Isici esibalulekile sokusebenza kwensimbi yesimanje, izithando zokuncibilika zokungeniswa zinikeza indlela enembile, ephumelelayo, kanye nemvelo yokuncibilikisa nokuhlanza izinsimbi. Lawa mathuluzi aguqule imikhakha eyahlukene, kusukela emalini eningi eya ekukhiqizeni ubucwebe, ngokusebenzisa imigomo kazibuthe kagesi. Imishini yokuncibilikisa i-induction kulindeleke ukuthi ibe nomthelela omkhulu ekuqondisweni kokucubungula kwensimbi okusebenzayo nokunobungani kwemvelo eminyakeni ezayo njengoba intuthuko yezobuchwepheshe iqhubeka nokuthuthukisa ukusebenza nokuklama kwayo. Thola imininingwane mayelana nesithando somlilo esincibilikisa induction ku-Hasung!

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjiniyela bemishini etholakala eningizimu yeShayina, edolobheni elihle nelikhula ngokushesha kwezomnotho, iShenzhen. Le nkampani ingumholi kwezobuchwepheshe emkhakheni wemishini yokushisa nokukhipha izinsimbi eziyigugu kanye nemboni yezinto ezintsha.

Ulwazi lwethu oluqinile kubuchwepheshe bokuphonswa kwe-vacuum lusenza sikwazi ukukhonza amakhasimende ezimboni ukuze afake insimbi exutshwe kakhulu, i-platinum-rhodium alloy edingekayo nge-vacuum ephezulu, igolide nesiliva, njll.

Ucingo: +86 17898439424

I-imeyili: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Ikheli: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115