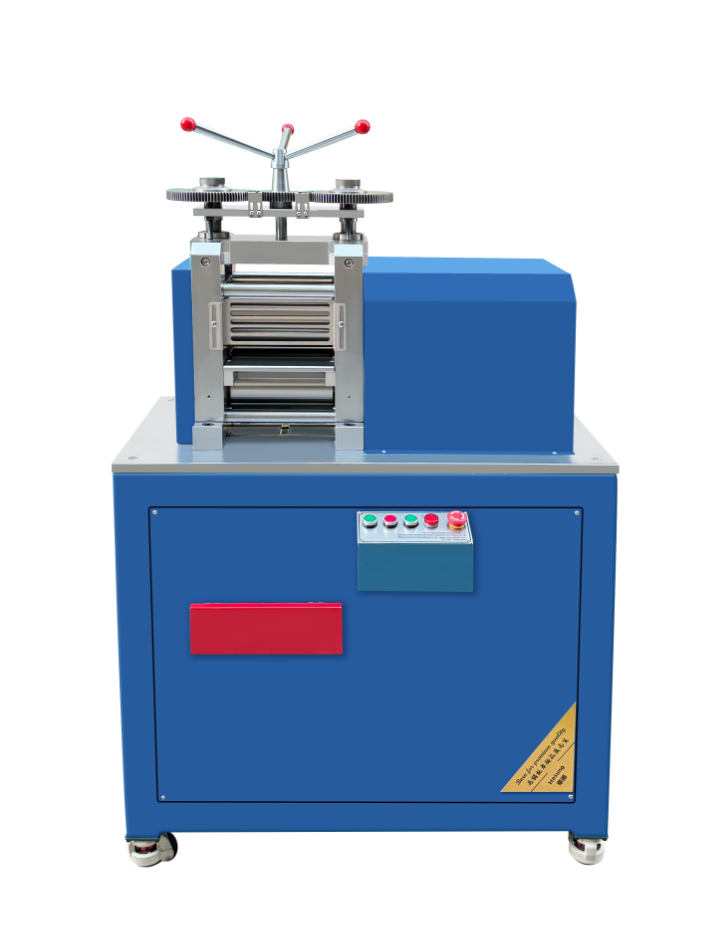

Hasung ke Moetsi oa Mechini ea ho Qhibilihisa le ho Fokotsa Tšepe ea Bohlokoa ho tloha ka 2014.

Leloala la motlakase la khauta le silevera le tla khothaletsa nts'etsopele ea indasteri joang?

1, Selelekela

Khauta, silevera le mabenyane, e le mekhabiso ea bohlokoa le thepa ea matsete, esale e le tsa bohlokoa sechabeng. Ka tsoelopele e tsoelang pele ea theknoloji, indasteri ea khauta, silevera le mabenyane le eona e lula e batla likhatelopele tse ncha tsa theknoloji ho ntlafatsa katleho ea tlhahiso, ho ntlafatsa boleng ba sehlahisoa, le ho fihlela litlhoko tse ntseng li eketseha tsa bareki. Joalo ka lisebelisoa tsa bohlokoa tsa ho lokisa, leloala la motlakase la khauta, silevera le mabenyane le bapala karolo ea bohlokoa ntlafatsong ea indasteri eohle ka boqapi ba theknoloji. Sengoliloeng sena se tla shebisisa hore na boqapi ba mahlale a mahlale a khauta, silevera, le mabenyane a ho roala motlakase o ka khothaletsa nts'etsopele ea indasteri.

2、 Theknoloji ea theknoloji ea khauta, silevera le mabenyane a ho roala leloala la motlakase

(1) Theknoloji ea machining e phahameng haholo

Lisebelisoa tsa khale tsa ho lokisa mabenyane a khauta le silevera li na le mefokolo e itseng ka ho nepahala, ho etsa hore ho be thata ho finyella litlhoko tse hlokahalang tsa lihlahisoa tsa mabenyane a phahameng bakeng sa lintlha le ho nepahala. Mofuta o mocha oa leloala la motlakase oa khauta, silevera le mabenyane o sebelisa theknoloji e tsoetseng pele ea ho laola lipalo le li-sensor tse nepahetseng, tse ka fihlelang ts'ebetso e nepahetseng haholo. Ka mohlala, ka ho laola ka nepo khatello, lebelo le mocheso oa leloala le bilikang, thepa ea khauta le silevera e ka phuthoa hore e be matlapa a masesaane a nang le botenya bo lekanang le bokaholimo bo boreleli, e leng se fanang ka motheo o molemonyana bakeng sa ho betla, ho kenya ka hare le mekhoa e meng e latelang.

(2) Sistimi ea taolo e bohlale

Mechini ea sejoale-joale ea khauta, silevera le mabenyane a roalang motlakase a na le litsamaiso tse bohlale tsa ho laola, tse ka fihlelang tlhahiso ea boiketsetso le ho beha leihlo hole. Basebelisi ba ka beha maemo a ts'ebetso habonolo le ho lekola boemo ba ts'ebetso ea nako ea nnete ea lisebelisoa ka li-touchscreens kapa software ea komporo, ba ntlafatsa haholo katleho ea tlhahiso le boiketlo ba ts'ebetso. Ntle le moo, sistimi e bohlale ea taolo e ka boela ea bokella le ho sekaseka lintlha nakong ea ts'ebetso ea machining, e fana ka motheo oa ho ntlafatsa ts'ebetso ea machining.

(3) Theknoloji ea ho boloka matla le ts'ireletso ea tikoloho

Ka ntlafatso e tsoelang pele ea tlhokomeliso ea tikoloho, indasteri ea ho lokisa mabenyane a khauta le silevera e boetse e batla ka mafolofolo litharollo tsa ho boloka matla le tikoloho. Mofuta o mocha oa leloala la motlakase oa khauta, silevera le mabenyane o sebelisa li-motor tse sebetsang hantle le mekhoa ea ho laola matla, e ka fokotsang tšebeliso ea matla. Ka nako e ts'oanang, liloala tse ling tsa motlakase li boetse li na le kalafo ea khase e tsoang le lits'ebetso tsa ho khutlisa metsi a litšila, ho fokotsa tšilafalo ea tikoloho.

(4) Theknoloji ea ho kopanya e mengata e sebetsang

E le ho finyella litlhoko tsa bareki ba fapaneng, tlhahiso ea theknoloji ea khauta le silevera ea mabenyane a ho roala leloala la motlakase e boetse e bonahala karolong ea ho kopanya mesebetsi e mengata. Mechini e meng e mecha ea motlakase e ke ke ea etsa ts'ebetso ea ho roala maqephe feela, empa hape e hlokomela mekhoa e fapaneng e kang ho taka terata, ho phunya, ho seha, joalo-joalo, ho ntlafatsa haholo bokahohle le katleho ea tlhahiso ea lisebelisoa.

3, Phello e Khothatsang ea Boqapi ba Theknoloji ho Tsoelopele ea Indasteri ea Khauta, Silevera le Mabenyane.

(1) Ntlafatsa boleng ba sehlahisoa

Theknoloji e phahameng ea ho sebetsa ka mokhoa o nepahetseng le tsamaiso e bohlale ea taolo ea khauta le silevera e roala mabenyane a motlakase e ka netefatsa ho nepahala ha sebopeho, boleng ba holim'a metsi, le ho tsitsisa ha sehlahisoa, kahoo ho ntlafatsa boleng ba sehlahisoa. Lihlahisoa tsa boleng bo holimo tsa mabenyane ha li kopane le takatso ea bareki feela ea botle, empa li boetse li ntlafatsa setšoantšo sa brand le tlholisano ea 'maraka.

(2) Eketsa katleho ea tlhahiso

Tlhahiso ea othomathike le theknoloji ea ho kopanya mesebetsi e mengata e tlisoang ke boqapi ba theknoloji e ka khutsufatsa haholo potoloho ea ts'ebetso le ho ntlafatsa ts'ebetso ea tlhahiso. Sena se bohlokoa haholo bakeng sa ho fihlela tlhoko ea 'maraka le ho fokotsa litšenyehelo tsa tlhahiso. Ho sa le joalo, tlhahiso e sebetsang e boetse e thusa likhoebo ho holisa sekhahla sa tsona sa tlhahiso le ho eketsa karolo ea mmaraka.

(3) Khothaletsa ntlafatso ea lihlahisoa

Mokhoa o mocha oa theknoloji oa leloala la motlakase oa khauta le mabenyane a silevera o fa baqapi sebaka sa boqapi le menyetla e mengata. Theknoloji e phahameng ea ho sebetsa ka mokhoa o nepahetseng e ka finyella meralo e rarahaneng haholoanyane, litsamaiso tse bohlale tsa ho laola li ka finyella motho ka mong, 'me mahlale a bolokang matla le a tikoloho a tsamaisana le sepheo sa bareki ba morao-rao sa nts'etsopele ea moshoelella. Tsena tsohle li tla tsamaisa boqapi ba lihlahisoa tsa khauta, silevera le mabenyane, ho fihlela litlhoko tse ntseng li eketseha tsa bareki.

(4) Ntlafatsa tlholisano ea indasteri

Boqapi ba theknoloji ke ntlha ea bohlokoa ho ntlafatseng tlholisano ea indasteri. Likhoebo tse nang le theknoloji e tsoetseng pele li ka hlahella 'marakeng 'me tsa hohela bareki le litaelo tse ngata. Ho sa le joalo, boqapi ba theknoloji bo ka boela ba khothaletsa tlholisano e phetseng hantle ka har'a indasteri le ho tsamaisa nts'etsopele ea indasteri eohle.

(5) Khothaletsa ntlafatso ea indasteri

Popontshwa ya thekenoloji ya leloala la motlakase le kolobisang mabenyane a khauta le silevera e tla tsamaisa tsoelopele ea theknoloji le ntlafatso ea indasteri ea indasteri eohle ea ho lokisa mabenyane a khauta le silevera. Phetoho ho tloha ho ts'ebetso ea matsoho ea setso ho ea ho tlhahiso e ikemetseng le e bohlale e ke ke ea ntlafatsa feela katleho ea tlhahiso le boleng ba sehlahisoa, empa hape e fokotsa matla a mosebetsi le ho ntlafatsa tikoloho ea ho sebetsa. Sena se tla thusa ho hohela talenta e ngata indastering le ho khothaletsa nts'etsopele ea eona ea moshoelella.

4, Mathata le Maano a Karabelo a Tobaneng le Boqapi ba Theknoloji

(1) Phephetso

Matsete a mangata a lipatlisiso le nts'etsopele ea theknoloji: Ho nchafatsoa ha theknoloji ea tshilo ea khauta, silevera le mabenyane a ho roala motlakase ho hloka chelete e ngata ea chelete le matsete a basebetsi, e leng se ka bakang bothata ba chelete e sa lekaneng bakeng sa likhoebo tse nyane le tse mahareng.

Khaello ea litalenta tsa tekheniki: Boqapi ba thekenoloji bo hloka tšehetso ea litsebi tse nang le tsebo le litsebo tsa profeshenale, 'me hajoale ho na le khaello e itseng ea litalenta tsa tekheniki indastering ea khauta, silevera le mabenyane, e leng ho etsang hore ho be thata ho fihlela litlhoko tsa boqapi ba theknoloji.

Ho hloka bonnete ba tlhokeho ea 'maraka: Liphihlello tsa ntlafatso ea theknoloji li hloka ho ananeloa le ho amoheloa ke' maraka, 'me tlhoko ea 'maraka ha e na bonnete, e leng se ka lebisang likotsing tse ntseng li eketseha tsa boqapi ba theknoloji.

(2) Leano la karabelo

Ho matlafatsa tšebelisano-'moho le puisano: Likhoebo li ka matlafatsa tšebelisano 'moho le liunivesithi le litsi tsa lipatlisiso, tsa etsa lipatlisiso le nts'etsopele ea theknoloji ka kopanelo, le ho fokotsa litšenyehelo tsa lipatlisiso le nts'etsopele. Ho sa le joalo, lik'hamphani tse ka har'a indasteri le tsona li ka matlafatsa puisano le tšebelisano-'moho, tsa arolelana liphihlelo le katleho ea ntlafatso ea theknoloji.

Ho hlaolela le ho hlahisa litalenta: Likhoebo li ka holisa sehlopha sa litalenta tsa tekheniki tse nang le tsebo le boiphihlelo ka tšebelisano 'moho le liunivesithi le koetliso ea kahare. Ka nako e ts'oanang, hoa khoneha ho ntlafatsa bokhoni ba boqapi ba theknoloji ba likhoebo ka ho hlahisa litalenta tsa maemo a holimo.

(3) Ela hloko tlhoko ea 'maraka: Ha likhoebo li kenya letsoho ntlafatsong ea theknoloji, li lokela ho ela hloko tlhoko ea 'maraka ka botlalo, li utloisise litlhoko le likhetho tsa bareki,' me li netefatse hore liphetho tsa ntlafatso ea theknoloji li ka ananeloa le ho amoheloa ke 'maraka.

5, Qetello

Tlhahiso ea theknoloji ea leloala la motlakase la khauta le silevera e bapala karolo ea bohlokoa ho nts'etsopele ea indasteri eohle. Ka tšebeliso ea theknoloji e phahameng ea ho sebetsa ka mokhoa o nepahetseng, tsamaiso e bohlale ea ho laola, ho boloka matla le theknoloji ea ho sireletsa tikoloho, le theknoloji ea ho kopanya mesebetsi e mengata, boleng ba lihlahisoa bo ka ntlafatsoa, katleho ea tlhahiso ea eketseha, tlhahiso ea lihlahisoa e ka khothaletsoa, tlhōlisano ea indasteri e ka ntlafatsoa, 'me ntlafatso ea indasteri e ka khothaletsoa. Leha ho le joalo, boqapi ba mahlale bo boetse bo tobane le mathata a mang, a hlokang hore likhoebo li matlafatse tšebelisano-'moho le puisano, ho hlaolela le ho hlahisa litalenta, le ho ela hloko tlhoko ea 'maraka ho tobana le liphephetso le ho fihlela nts'etsopele ea moshoelella. Ke lumela hore ka khothaletso ea boqapi ba theknoloji, indasteri ea ho lokisa mabenyane a khauta le silevera e tla tlisa bokamoso bo betere.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ke khamphani ea boenjiniere ba mechini e fumanehang ka boroa ho Chaena, motseng o motle le o holang ka potlako ka ho fetisisa moruong, Shenzhen. Khamphani ke moetapele oa theknoloji lefapheng la lisebelisoa tsa ho futhumatsa le ho lahla tšepe ea bohlokoa le indasteri ea thepa e ncha.

Tsebo ea rona e matla ea theknoloji ea ho lahla ka vacuum e re nolofalletsa ho sebeletsa bareki ba indasteri ho lahla tšepe e kopantsoeng ka bongata, motsoako oa platinum-rhodium o hlokahalang ka vacuum e ngata, khauta le silevera, jj.

Mohala: +86 17898439424

E-mail: sales@hasungmachinery.com.

WhatsApp: 0086 17898439424

Aterese: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115