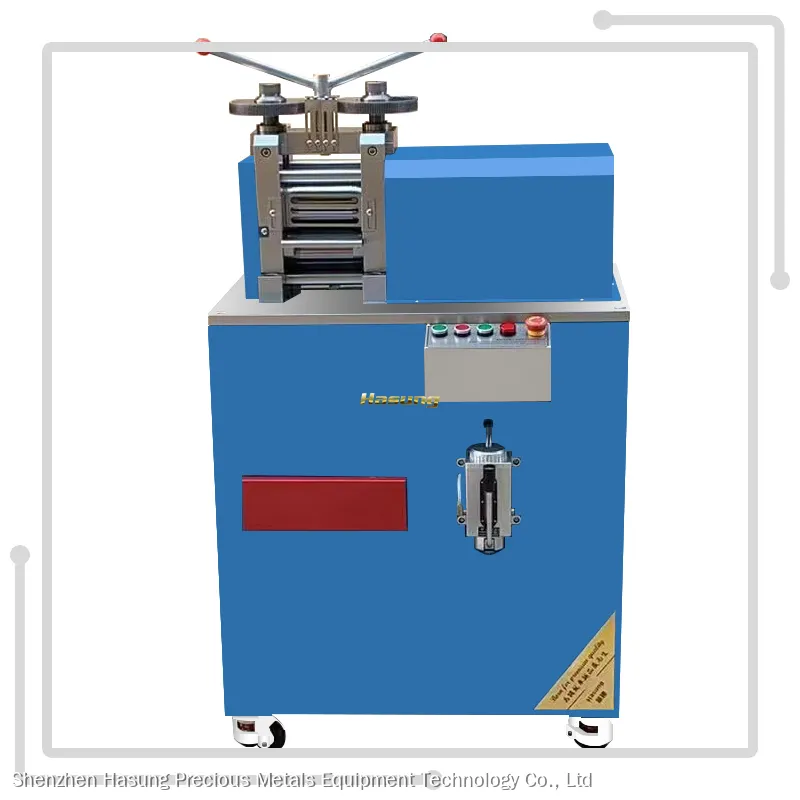

High-Tech Jewelry Rolling Mill - Customizable & Reliable

Product features

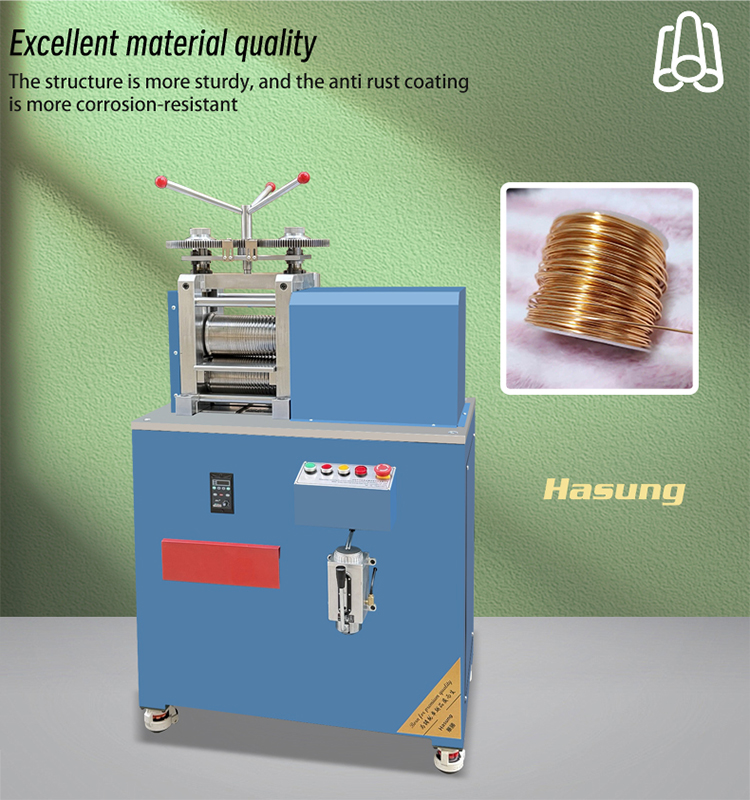

The High-Tech Jewelry Rolling Mill by Hasung offers customizable and reliable features for the wire drawing machine. With a roller diameter of 120 x width 210mm, D2 roller material, and a maximum opening of 30mm, this machine ensures smooth surface wire with accurate sizing and minimal loss. Additionally, the automatic lubrication, gear transmission, and optional automatic take-up feature provide convenience and efficiency in jewelry making processes.

Company profile

With a strong focus on innovation and quality craftsmanship, our company prides itself on offering high-tech jewelry rolling mills that are customizable and reliable. Our products are designed to meet the unique needs of jewelry makers, providing them with the tools they need to bring their creative vision to life. We are committed to providing exceptional customer service and support, ensuring that our clients have a seamless experience from purchase to usage. Trust in our brand for superior technology, personalized solutions, and a commitment to excellence in the jewelry making industry.

Why choose us

Our company is a leading manufacturer of high-tech jewelry rolling mills, offering a customizable and reliable solution for jewelry makers. With a focus on innovation and quality, we pride ourselves on providing top-of-the-line equipment that meets the needs of our customers. Our rolling mills are designed to ensure precision and efficiency in the jewelry making process, allowing craftsmen to create intricate and beautiful pieces with ease. Trust in our company for all your jewelry making needs, and experience the difference that our high-tech equipment can make in your creations.

Hasung’s gold silver jewelry wire rolling machine is a compact and bench-top system engineered for continuous, precision reduction of precious-metal wire. Driven by a quiet servo motor and controlled through an intuitive HMI, it produces mirror-finished round, half-round or square profiles from raw rod to fine wire in a single, uninterrupted pass. Quick-release roll cassettes can be swapped in under a minute, minimizing downtime between gauges or shapes. The electric wire rolling machine’s small footprint and standard single-phase plug make it ideal for jewelry factory, repair shops and small refineries seeking lab-grade precision without industrial noise or floor space.

Company Advantages

Frequently Asked Questions about melting equipment

With experienced, professional, and well-educated employees, Hasung Precious is efficient and excellent in developing products, one of which is jewelry electric wire rolling machine. It has some unique features. Technology is usually adopted for the design and manufacturing of the product.With regard to its serviceability and practicality, automatic wire rolling machine can be commonly seen in the field(s) of Wire Drawing Machines. Whether you are looking for gold wire rolling machines or High quality wire rolling machine manufacturers, Hasung is a solution for all your buying needs. We can offer you the prices that you need and quality that is good for you.

Product Description

Features

1.Servo-driven rolls for smooth, stepless speed control

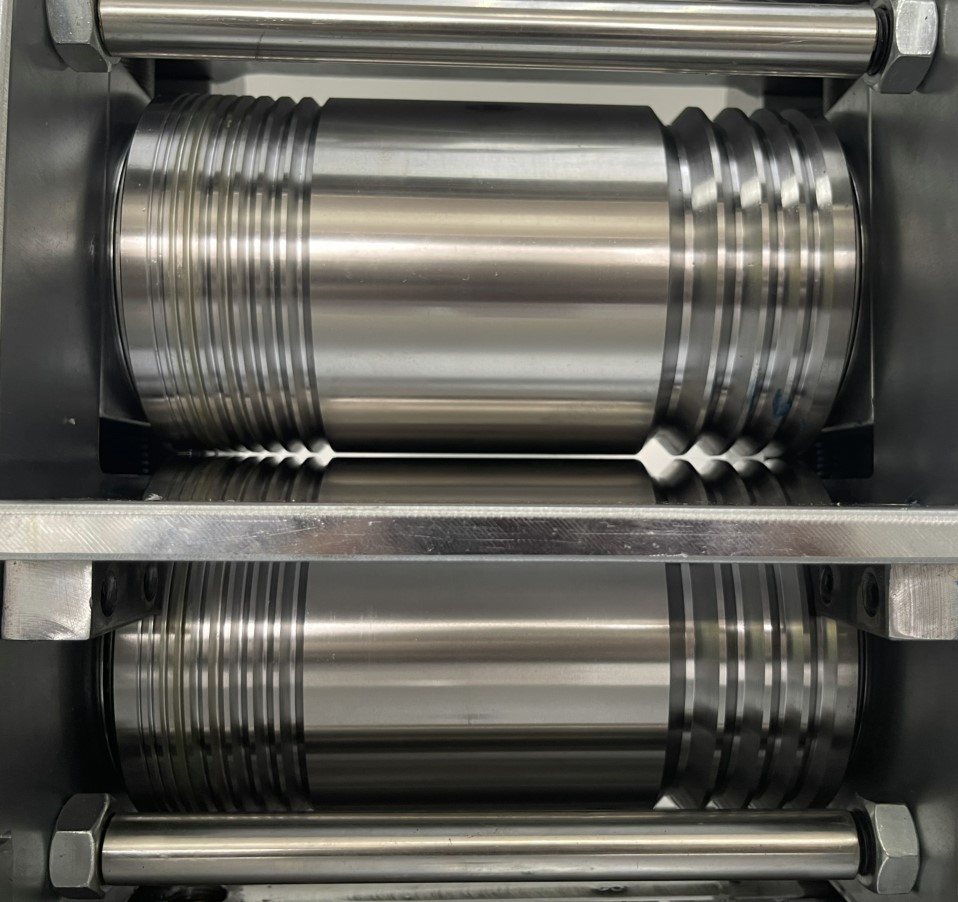

2.Water-cooled, mirror-polished tungsten rollers prevent overheating and deliver a bright finish

3.PLC touchscreen with recipe storage for gold, silver, platinum alloys—recall any profile in seconds

4.Quick-release roll cassettes swap tool-free in moments, cutting changeover downtime

5.Closed-loop coolant filtration keeps the bench clean and extends roller life

6.Bench-top footprint and quiet operation fit any jewelry factory or repair shop

Applications

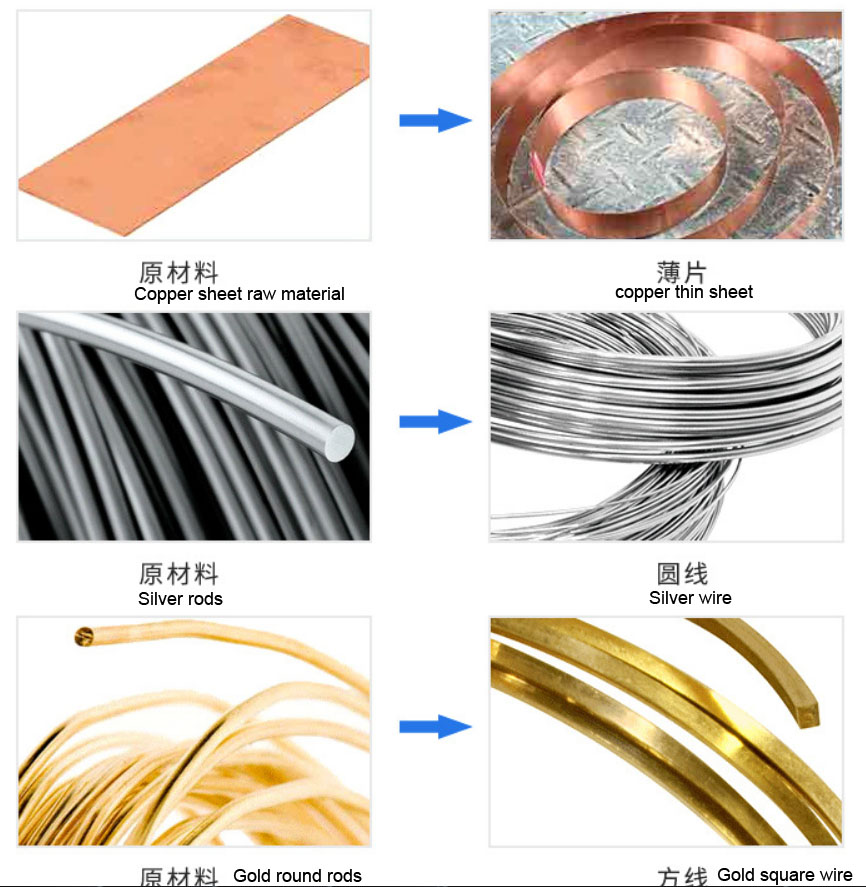

For gold, silver, copper, aluminum, Tin, etc

1.Produces ultra-fine round, half-round and square gold wire for delicate chain and filigree work.

2.Rolls sterling and Argentium silver stock for jump rings, clasps and earring posts.

3.Creates consistent platinum wire for high-end engagement ring shanks and prongs.

4.Supplies repair shops with custom gauge wire for sizing, retipping and stone setting.

5.Enables small refineries to redraw scrap into fresh, saleable wire in a single pass.

Specification of Sheet Rolling

Model No. | HS-5.5HP |

Voltage | 380V, 50/60Hz |

Power | 4KW |

Roller | diameter 120 x width 210mm |

Roller hardness | 60-61 ° |

Roller material | D2 (DC53 is optional) |

Maximum Opening | 30mm |

Speed | 30rpm/min. |

Dimensions | 780×580× 1400mm |

Weight | about 300kg |

Additional function | automatic lubrication; gear transmission |

Features | The maximum thickness of the film is 25mm when it's sheet rolling;smooth surface of the wire, accurate size, no low front loss; automatic take-up (optional); electrostatic dusting of the frame, decorative hard chromium |

Specification of Wire Rolling

Model No. | HS-5.5HP |

Voltage | 380V, 50/60Hz |

Power | 4KW |

Roller | diameter 120 x width 210mm |

Roller hardness | 60-61 ° |

Roller material | D2 (DC53 is optional) |

Square wire size | 12, 9.5, 7.5, 6, 5.5, 5.1, 4.7, 4.35, 4, 3.7, 3.45, 3.2, 3, 2.8, 2.65, 2.5, 2.35, 2.2, 2.05, 1.92, 1.8, 1.68, 1.58, 1.49, 1.43, 1.37, 1.31, 1.25, 1.19, 1.14, 1.1, 1.06, 1.03, 1mm |

Maximum input wire | 16mm |

Speed | 30rpm/min. |

Dimensions | 780×580× 1400mm |

Weight | about 300kg |

Additional function | automatic lubrication; gear transmission |

Features | The maximum thickness of the film is 25mm when it's sheet rolling;smooth surface of the wire, accurate size, no low front loss; automatic take-up (optional); electrostatic dusting of the frame, decorative hard chromium |

Combination Sheet & Wire Rolling is available

About Hasung

Shenzhen Hasung Precious Metals Equipment Co., Ltd. is a mechanical engineering company located in the south of China, in the beautiful and the most fastest economic growing city, Shenzhen. The company is a technological leader in the area of heating and casting equipment for the precious metals and new materials industry. Our strong knowledge in vacuum casting technology further enables us to serve industrial customers to cast high-alloyed steel, high vacuum required platinum-rhodium alloy, gold and silver, etc. Our mission is to build the most innovative heating and casting equipment for precious metal manufacturing and gold jewellery industry, providing customers with the highest reliability in your daily operations and the best quality. We are acknowledged in the industry as a technology leader. What we're deserved to be proud is our vacuum and high vacuum technology is the best in China. Our equipment, manufactured in China, is made of highest-quality components, apply worldwide famous brands components such as Mitsubishi, Panasonic, SMC, Simens, Schneider, Omron, etc. Hasung has proudly served the precious metal casting & forming industry with vacuum pressure casting equipment, continuous casting machine, high vacuum continuous casting equipment, vacuum granulating equipment, induction melting furnaces, gold silver bullion vacuum casting machine, metal powder atomizing equipment, etc. Our R & D department is always working on developing casting and melting technologies to suit our ever changing industry for the New Materials industry, Aerospace, Gold Mining, Metal Minting Industry, Research laboratories, Rapid Prototyping, Jewellery, and Artistic Sculpture. We do provide precious metals solutions for customers. We uphold the principle of "integrity, quality,cooperation, win-win" business philosophy,committed to creating first-class products and services. We always believe that technology changes the future. We specialize in designing and developing custom finishing solutions. Committed to provide precious metal casting solutions, coin minting solution, platinum, gold and silver jewellery casting solution, bonding wire making solution, etc. Hasung is looking for partners and investors for precious metals to develop technological innovation bringing outstanding return on investment. We are a company who only makes high end quality equipment, we don't take price as priority, we take value for customers.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115