Hasung - Tungsten Carbide Electrical Rolling Mill Machine for Gold Silver Copper

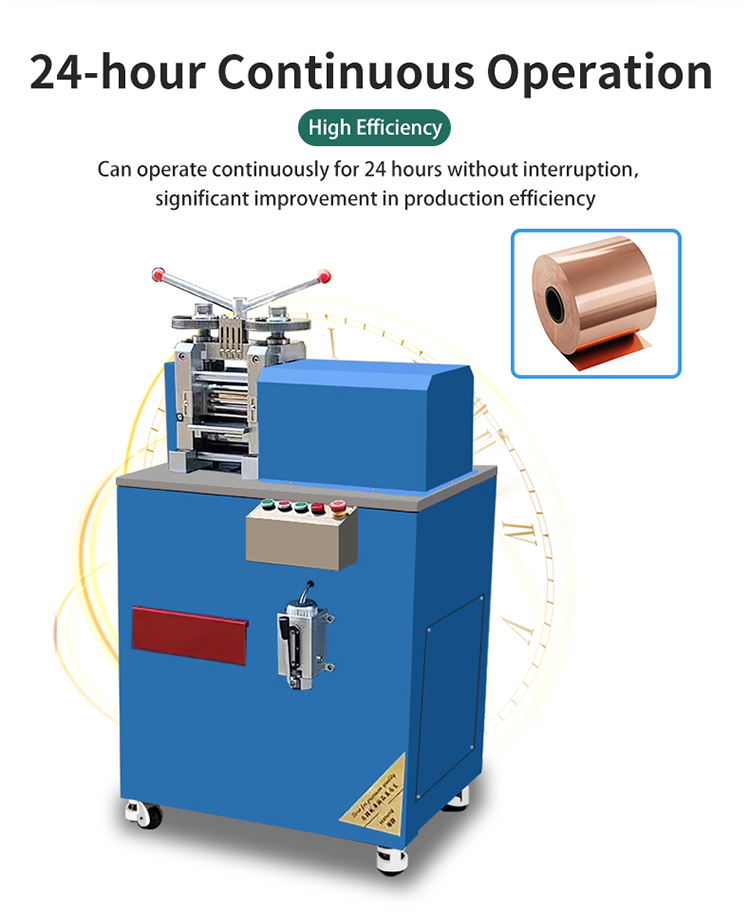

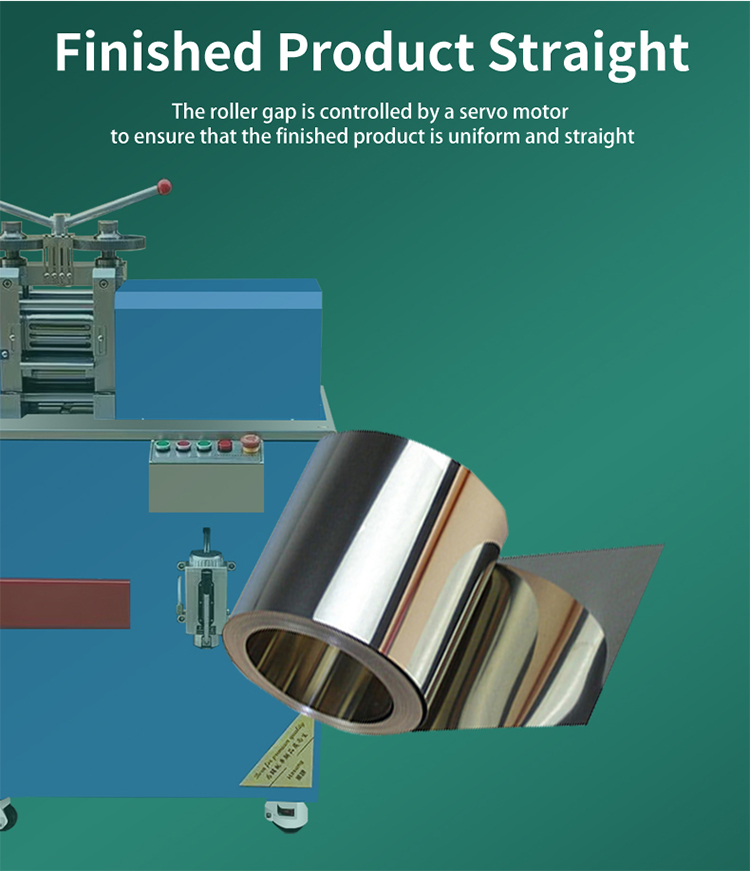

Hasung’s electrical rolling mill machine for tungsten-carbide, gold, silver and copper blends bench-top convenience with industrial force. Hardened rolls driven by a quiet servo motor reduce rod to fine wire in one continuous pass, while closed-loop cooling and PLC recipes deliver mirror finishes and micron precision for jewelry, electronics and EV conductors alike.

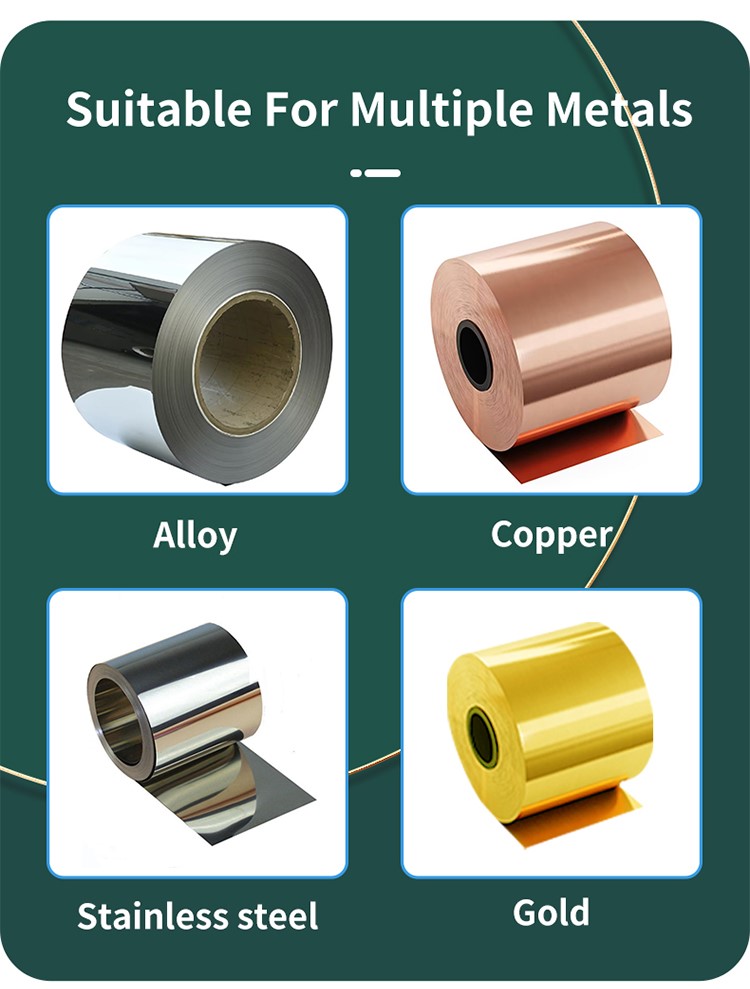

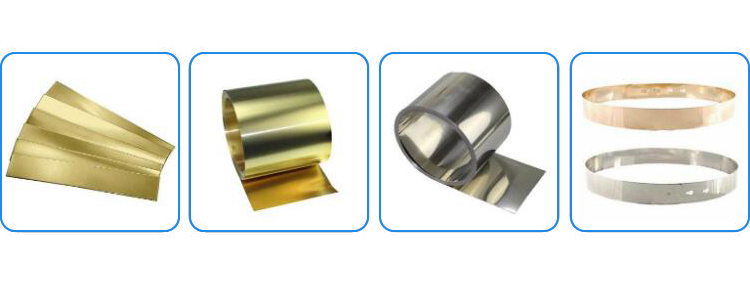

Driven by the competitive market, we have improved our technologies and been skilled at utilizing technology to manufacture the product. It has been proved that the product can be used in the application field(s) of jewelry tools & equipment and has an extensive application prospect. This tungsten carbide electric rolling mill is used for making mirror surface sheets for gold, silver, copper.

In order to better adapt to the diversified needs of customers, Hasung has been working hard to develop products. Technological innovation is the fundamental reason for us to achieve sustainable development. In order to be able to successfully meet the challenges, Hasung will continue to forge ahead on the road of technological innovation.

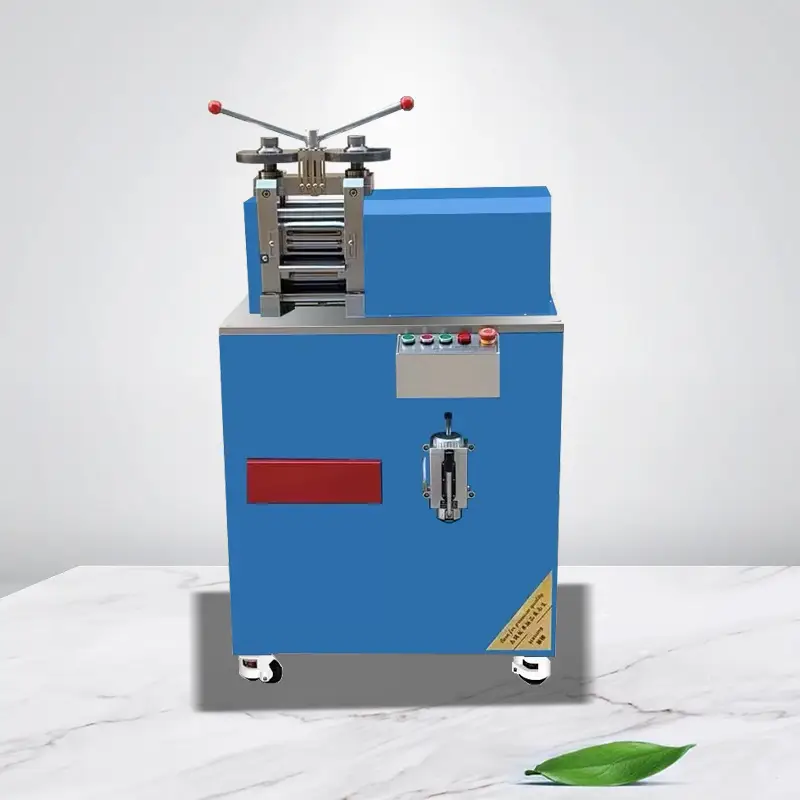

The electric jewellery rolling mill machine is a compact yet powerful bench-top system engineered to cold-roll tungsten-carbide, gold, silver and copper wire with laboratory precision. A quiet servo motor drives mirror-polished, tungsten-carbide rollers through a continuously variable speed range, allowing a single uninterrupted pass from rod to ultra-fine wire without intermediate annealing. The operator selects material and target profile on the color touchscreen; the PLC stores and recalls recipes for each alloy, automatically adjusting roll gap, tension and coolant flow to maintain micron-level tolerance and a bright, oxide-free finish.

| Brand Name: | Hasung | Place of Origin: | Guangdong, China |

| Model Number: | HS-M5HP | Jewelry Tools & Equipments Type: | Wire Drawing and Rolling Mills |

| Voltage: | 380V | Power: | 4KW |

| Roller Diameter: | 90x60mm; 90x90mm; 100x100mm; 120x100mm; 120x120mm | Thinnest size: | 0.1mm |

| Usage: | Jewelry Wire Rolling | Machine Dimensions: | 880*580*1400mm |

| CONDITION: | New | Certification: | CE ISO |

| Weight: | 450kg | Warranty: | 2 Years |

Jewelry rolling mill is mainly composed of up and down roller, roller support bearing and shaft sleeve, compaction and adjusting device, digital display system and drive components.

Add metal through extrusion, the metal thickness thinning, the surface is smooth.Pressure wheel surface is smooth, the product surface is smooth. Pressure roller surface is mirror effect, and then, the product surface is also a mirror effect.

Electric rolling mill for wire, it grinds groove corresponding to the circular, square shape in the upper and down pressure wheel surface , extrusion with different shape and size of the metal lines. It can also be in the upper and lower pressure wheel processing of the corresponding text and trademark patterns and other patterns, to get the desired effect.

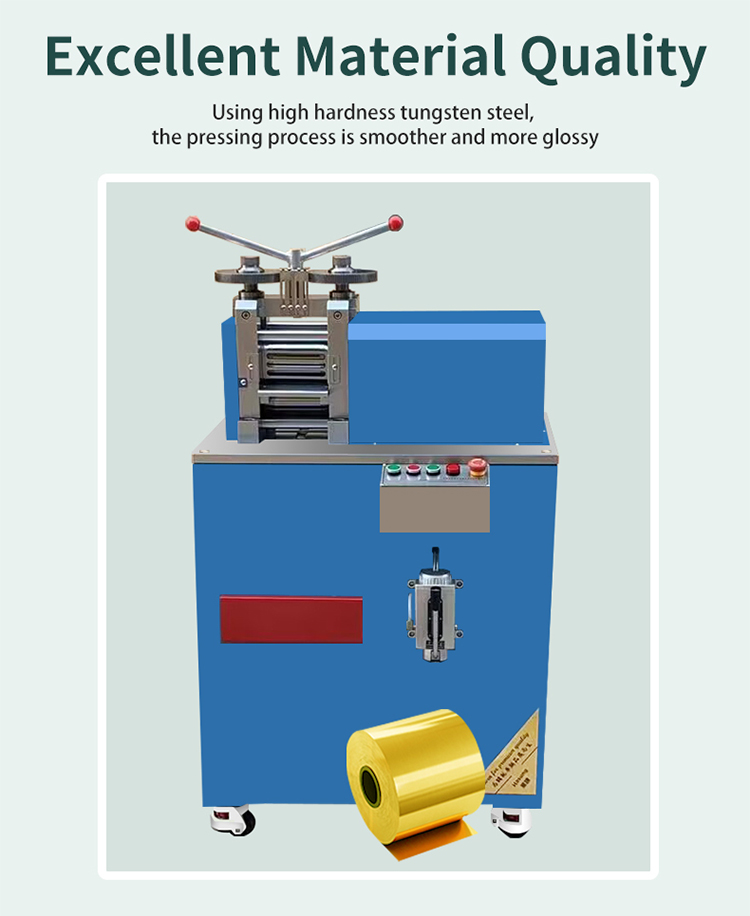

1. Electric jewellery rolling mill machine uses the high hardness of the rollers to produce material, simple and firm structure, small occupied space, low noise, convenient operation.

2. The moving roller adopts the linkage mechanism, the same as the same as the same as the above, to ensure that the thickness of the processed metal is uniform, and the precision of the finished product is guaranteed.

3. Multi - stage transmission, a variety of transmission structure, the combination of moderate speed, anti - Card dead.

4. Heavy machine body so that increase the stability of the equipment working.

5. Strictly control of the manufacturing precision of the equipment parts, machinery parts and components according to the precision of the drawing processing, the same types of interchangeable, convenient maintenance and time-saving.

6. The mirror reels rolling machine can roll sheet metal surface with a mirror effect.

Voltage: 380v; Power: 3.7kw; 50hz; Roller: diameter 100 × width 60mm; imported tungsten steel billet; tungsten steel hardness: 92-95 °; Dimensions: 880×580× 1400mm; weight: about 450kg; Automatic lubricating; universal transmission of gear box, pressing sheet thickness 10mm, thinnest 0.1mm; extruded sheet metal surface mirror effect; static powder spraying on the frame, decorative hard chrome plating, stainless steel cover, beautiful and practical Does not rust.

Q: Are you jewellery rolling machine manufacturer?

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and

casting equipment, especially for high tech vacuum and high vacuum casting machines.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

We are a reliable company and a supplier on .

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115