Hasung - Factory Supply Platinum Induction Melting Machine with 2Kg-8kg for Melting Gold Silver Platinum Palladium

As soon as Factory Supply jewellery machinery 2kg 3kg 4kg 5kg 6kg platinum induction melting machine gold smelting equipment was launched on the market, it received positive feedback from many customers, who said that this type of product can effectively solve their needs.Moreover,the product is widely used in Industrial Furnaces.

Shenzhen Hasung Precious Metals Equipment Co., Ltd has become a recognized leader in the Industrial Furnaces industry with its high-quality product and excellent service. The product is widely used to tackle the problems arising in the field(s) of Industrial Furnaces. Driven by the corporate vision of 'being the most professional manufacturer and the most reliable exporter in the international market', Shenzhen Hasung Precious Metals Equipment Co., Ltd will pay more attention to enhancing R&D strength, continually upgrade technologies, and optimize organization structure. We encourage all the staff to unite together in this process for creating a better future for the company.

Advantages:

3. Self-maufacturered controller board.

Technical Specification

| Model No. | HS-MU1 | HS-MU2 | HS-MU3 | HS-MU4 | HS-MU5 | HS-MU6 | HS-MU8 | HS-MU10 |

| Voltage | 380V 50/60Hz, 3 P | 380V 50/60Hz, 3 phase | 380V 50/60Hz, 3 phase | |||||

| Power | 10KW | 15KW | 15KW | 15KW/20KW | ||||

| Capacity (Gold) | 1kg | 2kg | 3kg | 4kg | 5kg | 6kg | 8kg | 10kg |

| Max Temp | 1600°C/2100°C | |||||||

| Melting Time | 1-2 min. | 1-2 min. | 2-3 min. | 2-3 min. | 3-5 min. | 2-3 min. | 3-5 min. | 5-8 min. |

| Temp Accuracy | ±1°C | |||||||

| PID temp control | Optional | |||||||

| Application | Platinum, Palladium, Stainless steel, Gold, K gold, silver, copper and other alloys | |||||||

| Cooling type | Water chiller(sold separately) or Running water (water pump sold separately) | |||||||

| Dimensions | 560x480x880mm | |||||||

| Net Weight | approx.60kg | approx. 62kg | approx. 65kg | approx. 66kg | approx. 68kg | approx. 70kg | approx. 75kg | approx. 80kg |

| Shipping weight | approx. 92kg | approx. 95kg | approx. 96kg | approx. 98kg | approx. 105kg | approx. 110kg | approx. 120kg | approx. 130kg |

P.S.:

Please contact us for your request of metals you need to melt.

Packing details:

Water chiller (water cooling system) sold separately if needed.

Description

Product Description"

Application:

Introducing the Induction Melting Furnace: Revolutionizing Metal Melting

Do you need a reliable and efficient metal melting solution? Our state-of-the-art induction melting furnaces are your answer. With its high quality, fine workmanship and fast melting capabilities, this furnace is designed to meet the diverse needs of metal melting operations. Whether you are processing small quantities or large quantities of metal, our induction melting furnaces are available in different capacities to meet your specific requirements.

Made with precision and advanced technology, our induction melting furnaces are perfect for industries such as foundries, metalworking and manufacturing. Its innovative design and superior performance make it a valuable asset for businesses looking to streamline their metal melting processes and increase productivity.

Main features and benefits:

1. High Quality: Our induction melting furnaces are manufactured to the highest standards, ensuring durability and reliability in the most demanding industrial environments. The use of high-quality materials and exquisite craftsmanship guarantee a long service life and consistent performance.

2. Fine workmanship: Every detail of our induction melting furnace is carefully designed to provide excellent results. From the design of the heating elements to the construction of the crucible, every component is precision crafted to ensure optimal efficiency and effectiveness.

3. Fast melting: With advanced induction heating technology, our furnace is able to quickly melt various types of metals, including steel, iron, copper, and aluminum. This speed and efficiency not only saves time but also reduces energy consumption, making it a cost-effective solution for metal melting operations.

4. Different production capacities: We understand that different companies have different production needs. That’s why our induction melting furnaces are available in different capacities, allowing you to choose the size that best suits your specific melting requirements. Whether you need a small, medium or large capacity furnace, we have the perfect solution for you.

5. User-friendly operation: Our induction melting furnaces are designed to be easy to use, with intuitive controls and user-friendly interface. This ensures operators can effectively manage the melting process with minimal training, resulting in increased productivity and reduced downtime.

6. Versatility: From melting and alloying to refining and casting, our induction melting furnaces are capable of performing a variety of metalworking tasks. Its versatility makes it a valuable asset to businesses involved in a variety of metalworking applications.

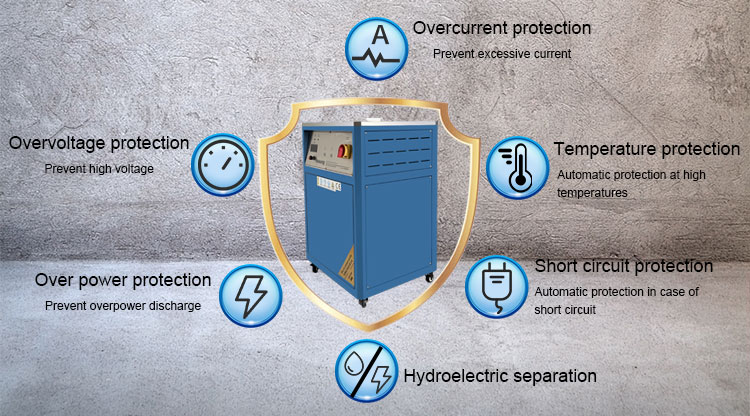

7. Safety Features: Safety is crucial in any industrial environment, and our induction melting furnaces are equipped with advanced safety features to protect the operator and the surrounding environment. From temperature monitoring to emergency shutdown systems, we prioritize the well-being of our users.

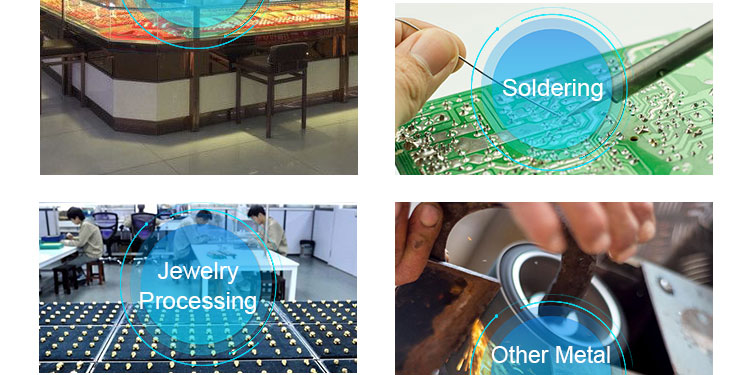

Application:

The versatility and efficiency of our induction melting furnaces make them suitable for a wide range of applications, including but not limited to:

- foundry

- Metal casting and forming

- Metal manufacturing

- Automotive and aerospace industry

- Electrical and electronic component manufacturing

- Jewelry and precious metal processing

All in all, our induction melting furnaces are a game-changer for businesses looking for reliable, high-performance metal melting solutions. Its combination of high quality, fine workmanship, fast melting capabilities and varying capacities make it a versatile and cost-effective choice for a variety of industrial applications. With our induction melting furnaces, you can take the efficiency and productivity of your metal melting process to new levels. Experience the difference with our advanced induction melting furnaces and take your metalworking operation to the next level.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. is a mechanical engineering company located in the south of China, in the beautiful and the most fastest economic growing city, Shenzhen. The company is a technological leader in the area of heating and casting equipment for the precious metals and new materials industry.

Our strong knowledge in vacuum casting technology further enables us to serve industrial customers to cast high-alloyed steel, high vacuum required platinum-rhodium alloy, gold and silver, etc.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115