Best VIM vacuum induction casting machine Palladium Platinum vacuum induction melting furnace Company - Hasung

VIM vacuum induction casting machine Palladium Platinum vacuum induction melting furnace compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Hasung summarizes the defects of past products, and continuously improves them. The specifications of VIM vacuum induction casting machine Palladium Platinum vacuum induction melting furnace can be customized according to your needs.

With strong ability of product research and development, Shenzhen Hasung Precious Metals Equipment Co., Ltd ensures new products are launched on a regular basis. Our new product Hasung VIM vacuum induction casting machine palladium vacuum induction melting furnace for sale is a totally new series and has different features. Gold Bar Vacuum Casting Equipment In order to be able to successfully meet the challenges,Shenzhen Hasung Precious Metals Equipment Co., Ltd will continue to forge ahead on the road of technological innovation. In addition, it will also work hard to analyze the changing needs of the market and create better products for customers according to their needs.

The First-Class Quality and Technology for Precious Metals Equipment Manufacturer in China.

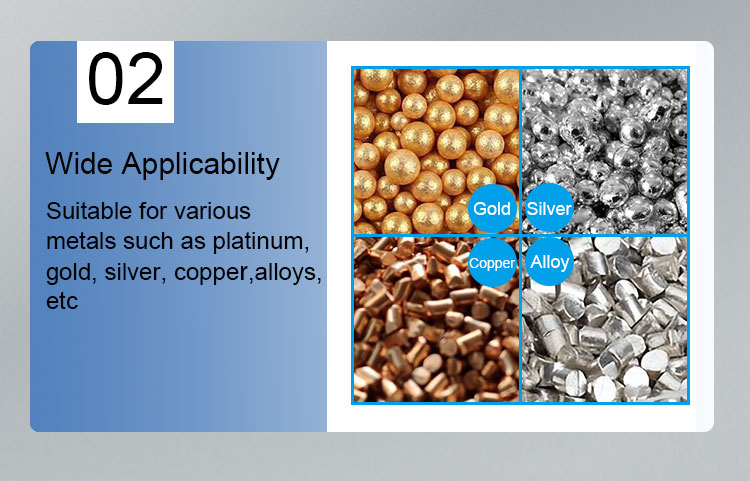

Application:

With our vacuum melting system, you'll get very fast and beautiful melting and casting job. This melting system is applied for melting gold, platinum, palladium, silver, copper with high vacuum condition.

Description

1. Adopting medium frequency induction, the melting time is short and the work efficiency is high.

2. The use of a high vacuum water-cooled casting chamber can prevent the oxidation of metal materials and the mixing of impurities, making it suitable for melting high-purity metal materials or those containing easily oxidizable elements.

3. Adopting mechanical stirring function under high vacuum state, the color is free of segregation.

4. The graphite crucible is melted under high-purity inert gas protection, so the oxidation loss is minimal.

5. Adopting automatic pouring and pouring, the operation is simpler.

6. During the pouring process, the mold adopts automatic heating to better ensure the pouring quality.

7. Equipped with a secondary feeding function, it can effectively control the time for adding low-temperature metals.

Technical Specification

Model No. | HS-HVQ1 | HS-HVQ2 |

Power | 15KW | 30KW |

Voltage | 380V ; 50/60Hz | |

Max Temp | 2200°C | |

Melting Time | 2-3 min. | 4-6 min. |

Temp Accuracy | ±1°C | |

PID temp control | Yes | |

Capacity | 1kg (Au/Pt) | 4kg (Au/Pt) |

Application | Platinum, Palladium, Gold, silver, copper and other alloys | |

Cooling type | Water chiller(sold separately) | |

Vacuum Degree | vacuum level degree 10-2 Pa, 10-3 Pa, 10-5 Pa,6.7x10-3Pa, 6.67x10-4 Pa (Optional) | |

Shielding Gas | Nitrogen/Argon | |

Operation Method | One-key operation to complete the entire process, POKA YOKE foolproof system | |

Control System | Mitsubishi PLC+Human-machine interface intelligent control system (optional) | |

Dimensions | 1776x1665x1960mm | |

Weight | approx. 480kg | |

Other capacities could be customzied.

Title: Exploring the Advantages of Metal Vacuum Induction Melting Furnaces

Metal vacuum induction melting (VIM) furnaces are key components in the production of high-quality metal alloys. These advanced furnaces utilize the principles of induction heating and vacuum technology to melt and refine metals, resulting in superior material properties. In this blog, we’ll take a closer look at the inner workings of VIM furnaces, their applications, and the many advantages they offer in metal manufacturing.

Learn about metal vacuum induction melting furnaces

Metal vacuum induction melting furnace is a special equipment for melting and refining metal under vacuum conditions. The working principle of this furnace is electromagnetic induction. High-frequency alternating current passes through the coil to generate a strong magnetic field. When a conductive metal is placed within this field, eddy currents are induced, causing the metal to heat up quickly and evenly.

The vacuum environment within a furnace serves a variety of purposes. First, it prevents oxidation and contamination of molten metal, ensuring the production of high-purity alloys. Additionally, since there is no air pressure, volatile impurities and gases can be removed from the molten metal, further improving its quality.

Application of metal vacuum induction melting furnace

Metal vacuum induction melting furnaces are widely used in the production of special alloys, high-temperature alloys and high-performance metals. These materials are critical in industries such as aerospace, automotive, energy and medical, which require superior mechanical properties, corrosion resistance and high temperature performance.

Especially high-temperature alloys are the focus of VIM furnace applications. Typically based on nickel, cobalt or iron, these advanced alloys have exceptional strength, heat resistance and creep properties, making them indispensable in the manufacture of turbine blades, aerospace components and industrial gas turbines.

Advantages of metal vacuum induction melting furnace

1. Excellent material quality: The vacuum environment and precise control of the smelting process result in alloys with excellent purity, extremely low gas content and uniform composition, resulting in improved mechanical and metallurgical properties.

2. Enhanced alloy uniformity: The rapid and efficient mixing of molten metal within the VIM furnace promotes uniform distribution of alloying elements, ensuring consistent material properties throughout the final product.

3. Reduced Inclusions and Defects: The absence of atmospheric contaminants and the ability to remove impurities during the melting process helps significantly reduce inclusions and defects, thereby enhancing the overall integrity of the metal.

4. Custom alloy development: VIM furnaces are capable of producing custom alloys tailored to specific industrial requirements, allowing the creation of innovative materials with customized properties.

5. Energy efficiency: The induction heating process coupled with a vacuum environment can effectively utilize energy and reduce heat loss, thereby saving costs and environmental benefits.

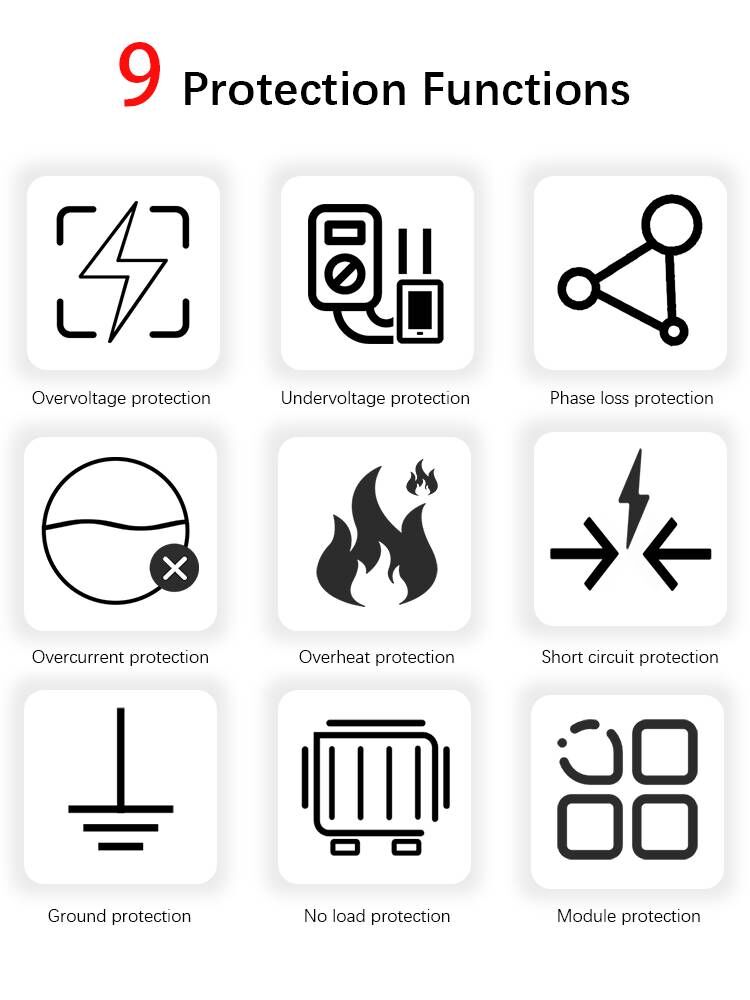

6. Process control and automation: VIM furnaces are equipped with advanced control systems that can precisely adjust temperature, alloy composition and other parameters to obtain consistent and repeatable results.

In summary, metal vacuum induction melting furnaces play a key role in the production of high-quality metal alloys for a variety of industrial applications. Their ability to create high-quality materials with exceptional properties, coupled with the advantages of precise process control and energy efficiency, makes them indispensable in modern metal manufacturing. As technology continues to advance, VIM furnaces are expected to further revolutionize the development of advanced materials, driving innovation and progress across industries.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115