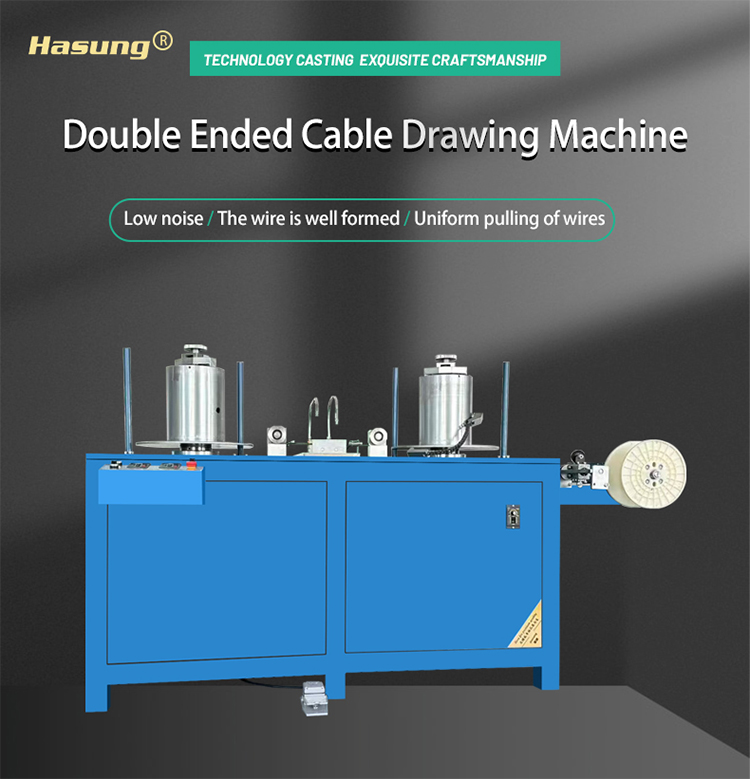

Hasung - Precious Metals Wire Drawing Machine for Gold Silver Jewellery Rolling Mills & Wire Drawing

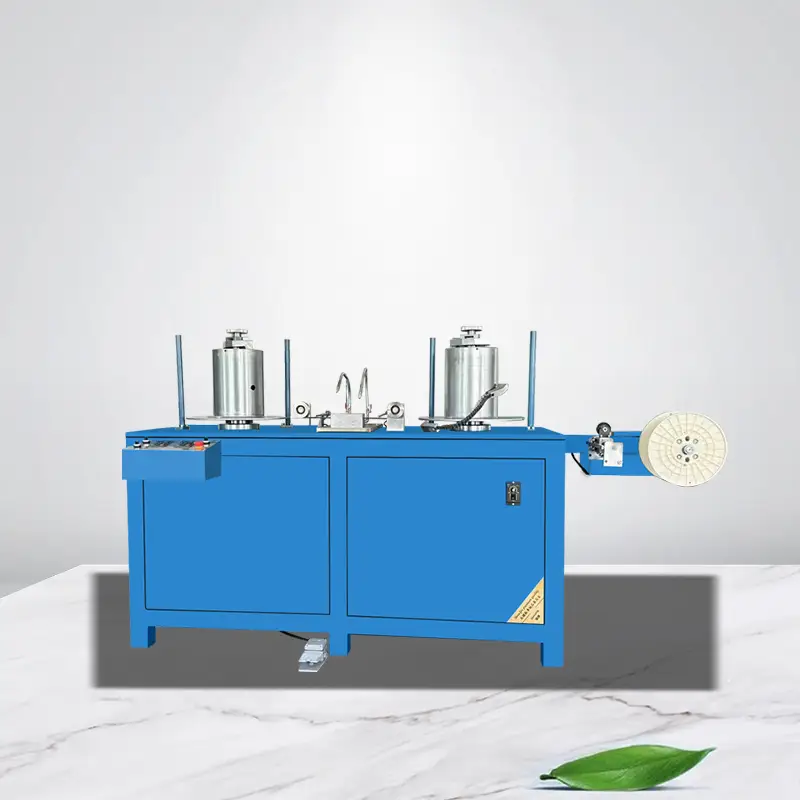

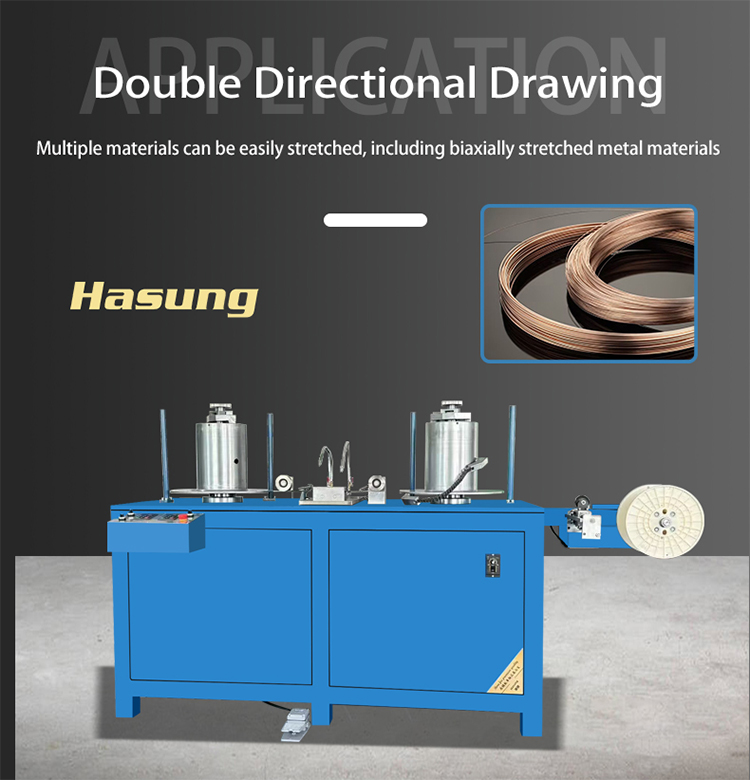

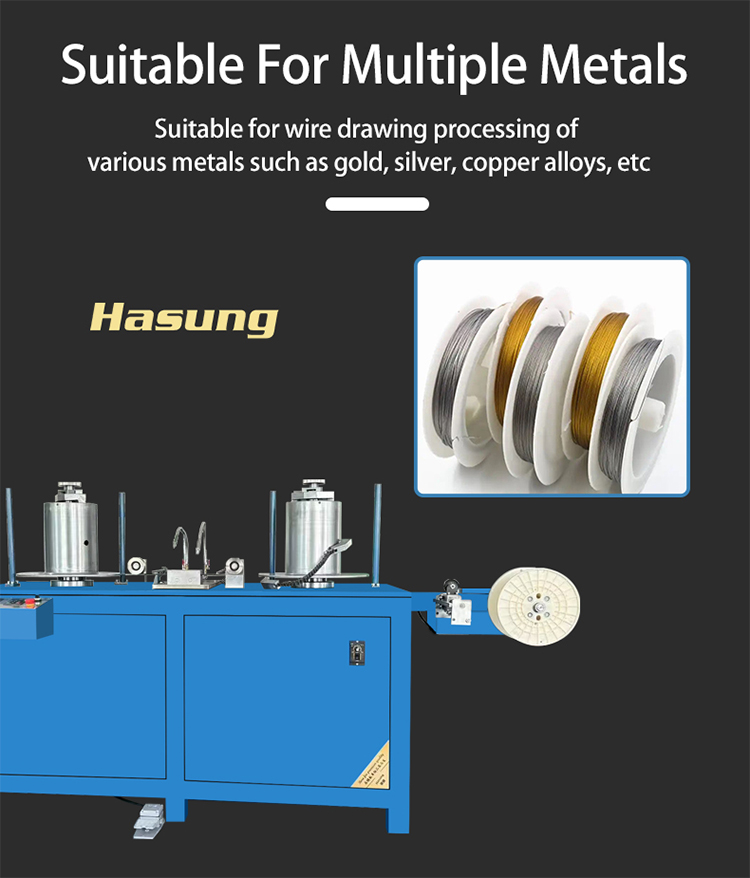

The Hasung precious metal wire drawing machine is a specialized solution designed for jewelry manufacturers, refineries, and industrial workshops that require precision wire production from gold, silver, and other precious metals. Engineered for stability, efficiency, and durability, this metal wire drawing machine supports wire diameters ranging from 0.3mm to 2mm, ensuring high-quality output for intricate jewelry designs, industrial applications, and investment products.

Gold wire drawing machine & silver wire drawing machine has passed the tests conducted by our professional QC inspectors. Using materials that are offered by reliable raw materials suppliers, precious has stable yet powerful performance. Our jewellery wire drawing machine has so many advantages which are newly and independently developed, creating plenty of benefits.

FAQ

Q1. What components make up the machine’s structure?

A1: Main Drawing Unit: Includes two-way wire passages for bidirectional drawing.

Die Set: Adjustable dies for precise wire diameter control.

Motor & Gearbox: High-torque motor with speed control (up to 70 circles/min).

Foot Pedal: For hands-free operation and safety.

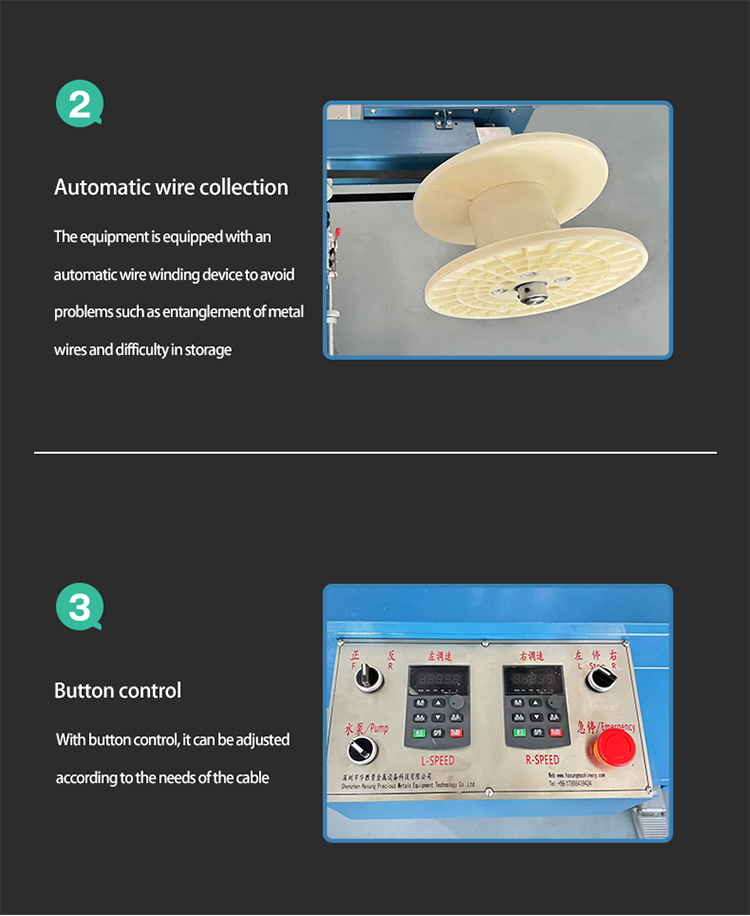

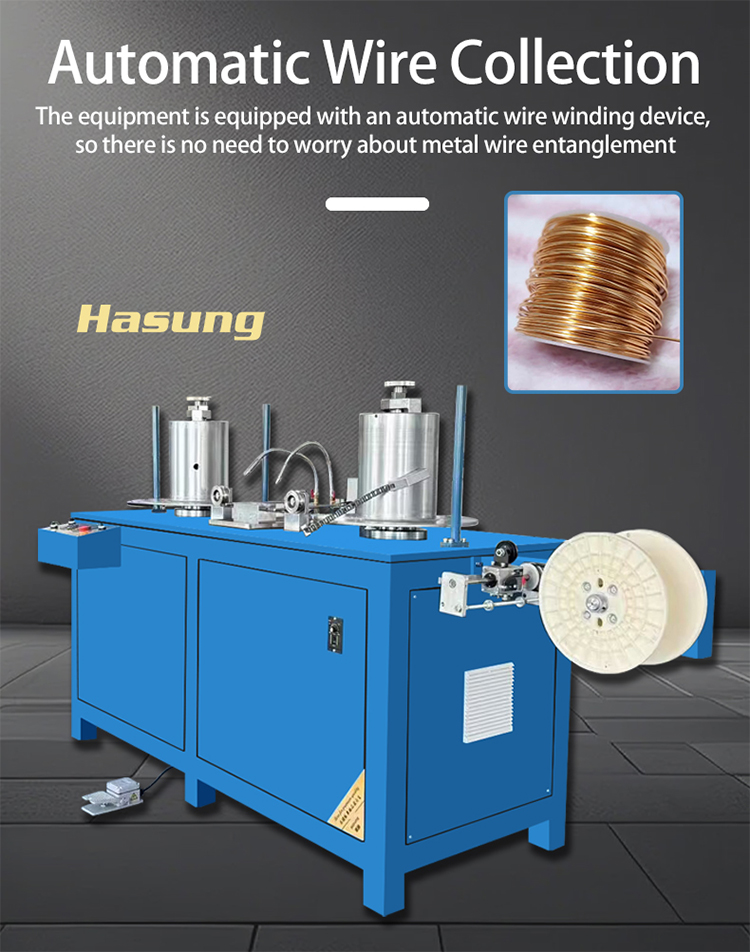

Spooling System: Left-side spool for automatic winding after drawing.

Control Panel: Adjusts speed, tension, and direction.

Q2. What advantages does the machine offer over traditional wire drawing methods?

A2: 200–300% Faster Production: Eliminates rethreading (unlike single-head machines).

Cost-Effective: Reduces labor and material waste.

Consistent Quality: Minimizes human error in wire thickness/shape.

Energy Savings: Lower power consumption vs. competitors.

Durable Design: Hardness rating of 62° for long-lasting performance.

Q3. How does the machine ensure precision and durability?

A3: Adjustable Speed Control: Optimizes drawing for different wire diameters.

High-Hardness Dies (62°): Reduces wear and ensures consistent wire shape.

Premium Components: Uses Mitsubishi, Siemens, SMC, and Omron parts for reliability.

Rigorous Testing: 100% QC inspection before shipment.

Q4. Can the machine be customized for specific needs?

A4: Die Customization: Adjust wire diameter range (e.g., 0.1–8mm).

Voltage Adjustment: 220V/380V/440V options for global use.

Brand Integration: Logo/label printing (minimum order: 1 unit).

Safety Upgrades: Emergency stop buttons, protective covers.

Q5: What can we do if we have problems with your machine while using?

A5: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance.

If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you.

Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115