Hasung - 10HP Jewelry Laminate Machine Electric Jewellery Rolling Mill Machine

The Hasung 10HP Electric Jewelry Rolling Mill Machine is designed for jewelry makers, goldsmiths, and metalworking professionals. Powered by a robust 10HP motor, this machine excels in flattening, reducing, and texturing precious metals such as gold, silver, platinum, and copper. Its precision engineering and user-friendly design make it ideal for creating sheets, wires, and custom textures for jewelry, art, and industrial applications.

Hasung grasp the new market trends, insight into the actual needs of customers, relying on advanced production technology and accurate market positioning, successfully launched 10HP jewelry laminate machine electric rolling mill machine. Our jewellery rolling mill product can be tailored to suit you perfectly. Hasung always stick to the market-oriented business philosophy and regard 'honesty & sincerity' as the enterprise tenet. We are trying to establish a sound distribution network and aim to provide customers all over the world with the best services.

| Brand Name: | Hasung | Place of Origin: | Guangdong, China |

| Model Number: | HS-10HP | Jewelry Tools & Equipments Type: | MOLDS |

| Brand: | Hasung | Product name: | 10HP Sheet Jewelry Rolling Mill Machine |

| Voltage: | 380 volts; 50/60hz | power: | 7.5kw |

| Weight: | Approx. 850kg | Warranty: | 2 Years |

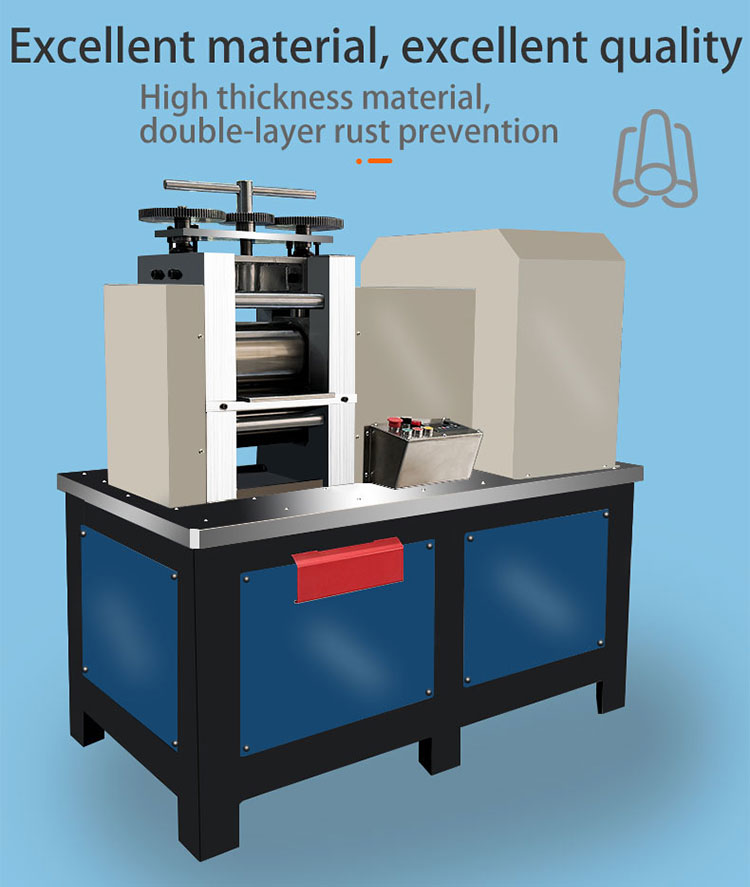

| Usage: | for precious metals sheet rolling | Dimension: | 1080x580x1480mm |

| Type: | Jewelry Making Machine | Quality: | Normal |

Structure & Components:

1.Motor & Drive System:

10HP jewellery rolling mill motor with variable frequency drive (VFD) for adjustable speed.

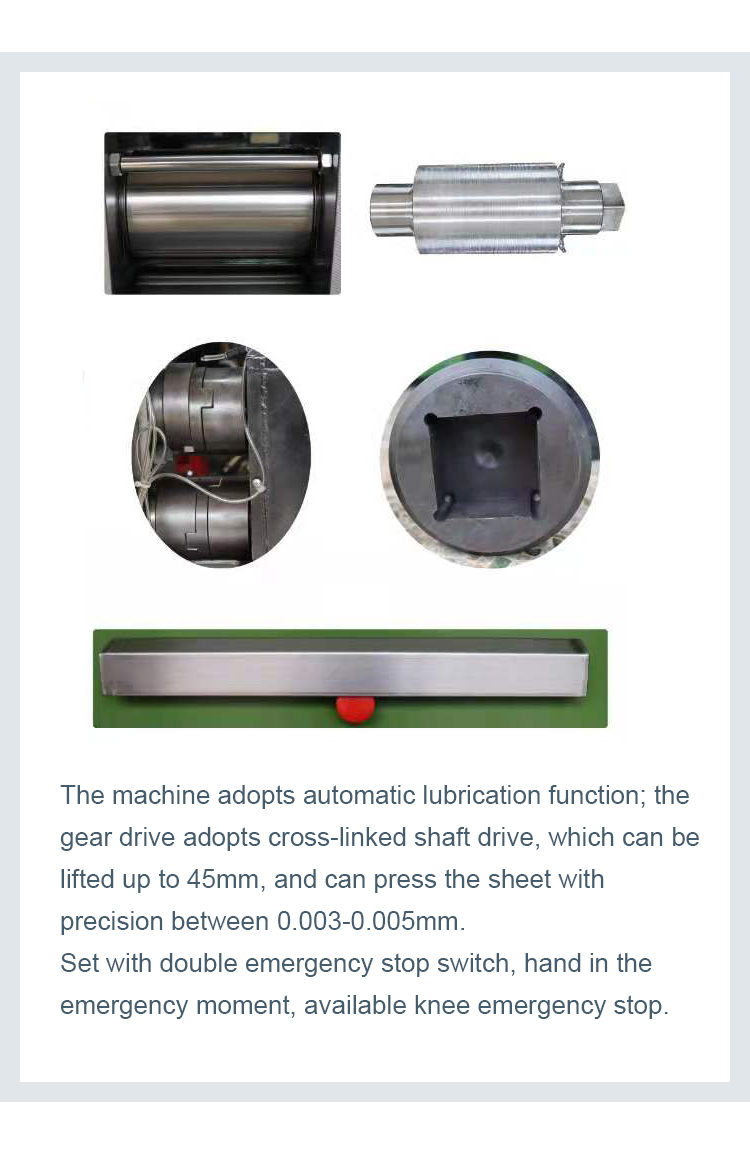

2.Rollers:

Hardened steel rollers (pair) with a diameter of 150mm and a width of 80mm.

Adjustable gap from 0.1mm to 6mm for different thicknesses.

3.Frame:

Heavy-duty steel construction with anti-vibration feet.

4.Safety Features:

Emergency stop button, overload protection, and safety guards.

5.Control Panel:

Digital display for speed, direction, and operational status.

Advantages:

▶High Efficiency: Reduces manual labor and speeds up production.

▶Precision Control: Ideal for creating intricate designs and thin sheets.

▶Versatility: Supports multiple metals and textures (flat, patterned, wire).

▶Durability: Built to withstand heavy use in professional workshops.

PRODUCT SPECIFICATIONS

MODEL NO. | HS-10HP 10HP Electric Jewellery Rolling Mill | |

Brand Name | HASUNG | |

Voltage | 380V, 50/60Hz 3 phases | |

Power | 7.5KW | |

Roller | diameter 150 × width 220mm | |

| Roller material | D2 (DC53 is optional) | |

hardness | 60-61 ° | |

Dimensions | 1100×700×1500mm | |

Weight | approx. 850kg | |

Advantage | The maximum thickness of the tablet is 30mm, the frame is electrostatically dusted, the body is plated with decorative hard chrome, and the stainless steel cover is beautiful and practical without rust. Two speed. | |

After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service | |

Our confidence | Customers could compare our machine to other suppliers then you will see our machine will be your best choice. | |

1.Powerful 10HP Motor:

High torque output for effortless rolling of thick metals.

Variable speed control for versatility in different applications.

2.Precision Rolling:

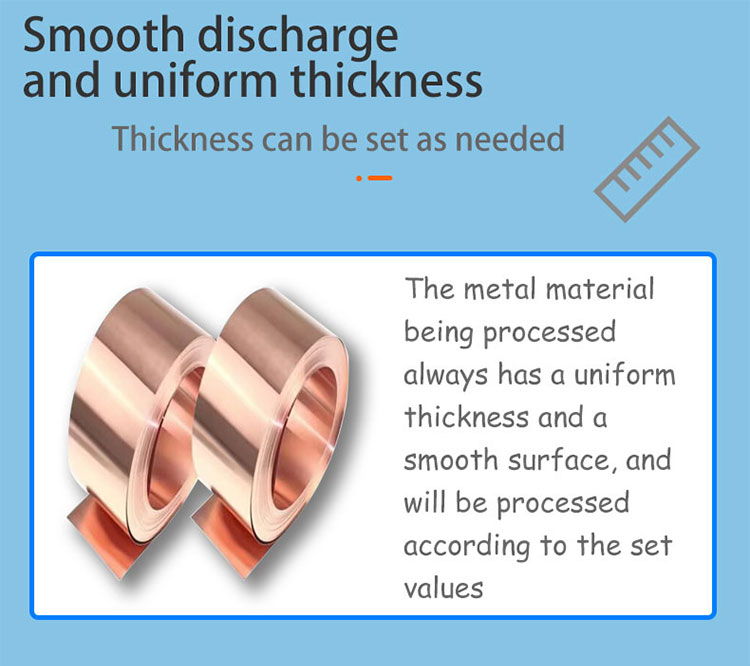

Adjustable rollers with a minimum gap of 0.1mm for ultra-thin sheets.

Uniform pressure distribution ensures consistent thickness.

3.Durable Construction:

Hardened steel rollers for long-lasting performance.

Heavy-duty frame minimizes vibration during operation.

4.User-Friendly Design:

Intuitive control panel with emergency stop and speed adjustment.

Easy-to-access rollers for quick maintenance and cleaning.

5.Customization Options:

Custom logos, packaging, and graphic designs available (Min. Order: 1 unit).

How It Works:

1.Material Preparation:Metal (ingot, wire, or scrap) is heated (if needed) for easier rolling.

3.Rolling Process:Metal is fed between the rollers, which compress and flatten it.Adjustable gap allows for gradual thickness reduction.

4.Annealing (Optional):For gold and silver, periodic annealing may be required to prevent cracking.

5.Final Product:Produces sheets, wires, or textured metal for jewelry, sculptures, or industrial use.

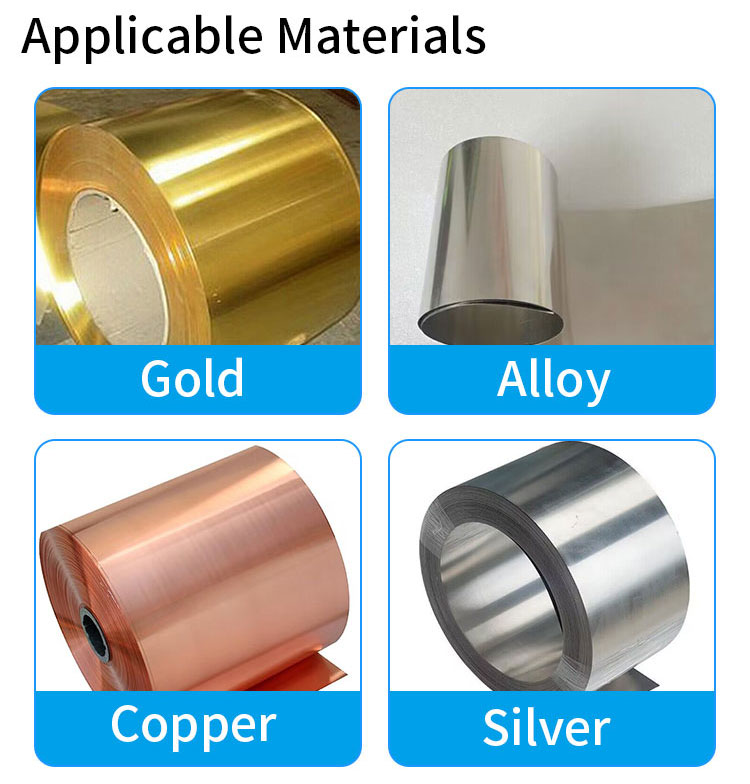

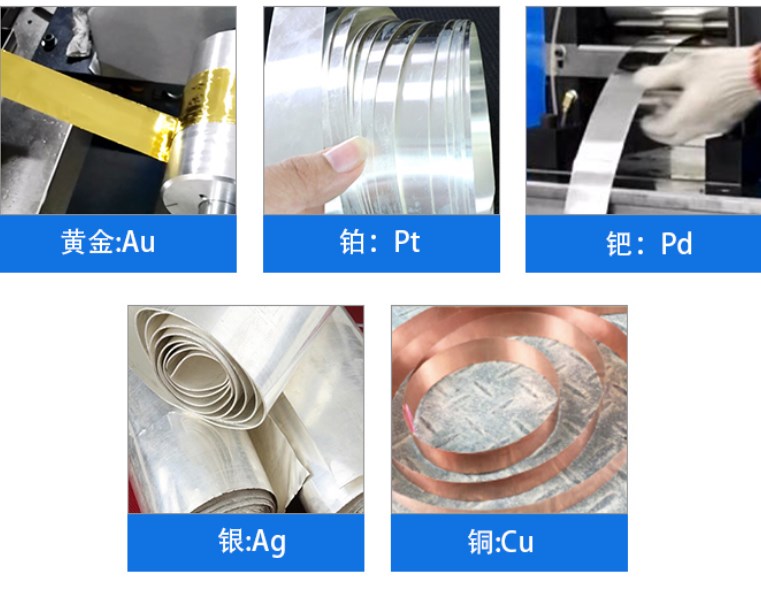

Processable Metal Materials:

Gold: 24K, 22K, 18K, and gold alloys

Silver: Sterling silver, fine silver, and silver alloys

Platinum & Palladium: For high-end jewelry

Copper & Brass: For decorative and industrial applications

Aluminum & Nickel Silver: For lightweight or corrosion-resistant needs

Electric Rolling Mill Machine Applications:

1.Jewelry Making:Flattening gold and silver for rings, bracelets, and pendants.Creating custom textures (hammered, wire-brushed, etc.).

2.Art & Sculpture:Producing metal sheets for metalworking and art installations.

3.Industrial Use:Manufacturing electrical contacts, connectors, and microcomponents.

4.Dental & Medical:Rolling precious metals for dental crowns and implants.

FAQ

Q: Are you manufacturer?

A: Yes, we are the original manufacturer of the highest quality products for precious metals smelting and casting equipment, especially for high tech vacuum and high vacuum casting machines. Welcome to visit our factory in Shenzhen, China.

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115