Hasung Jewellery Wire Rolling Mills Machine 8 10 HP First Class Quality

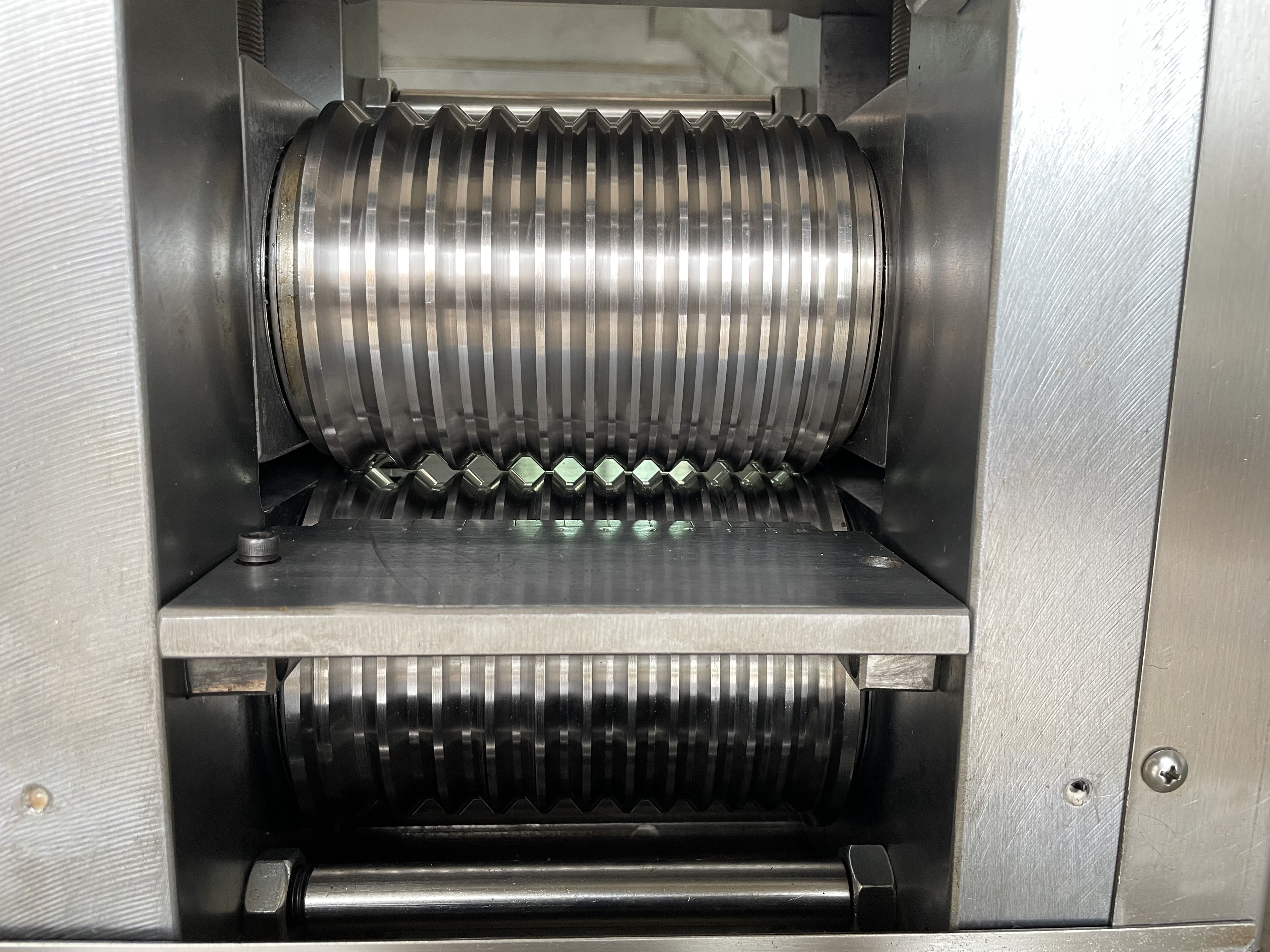

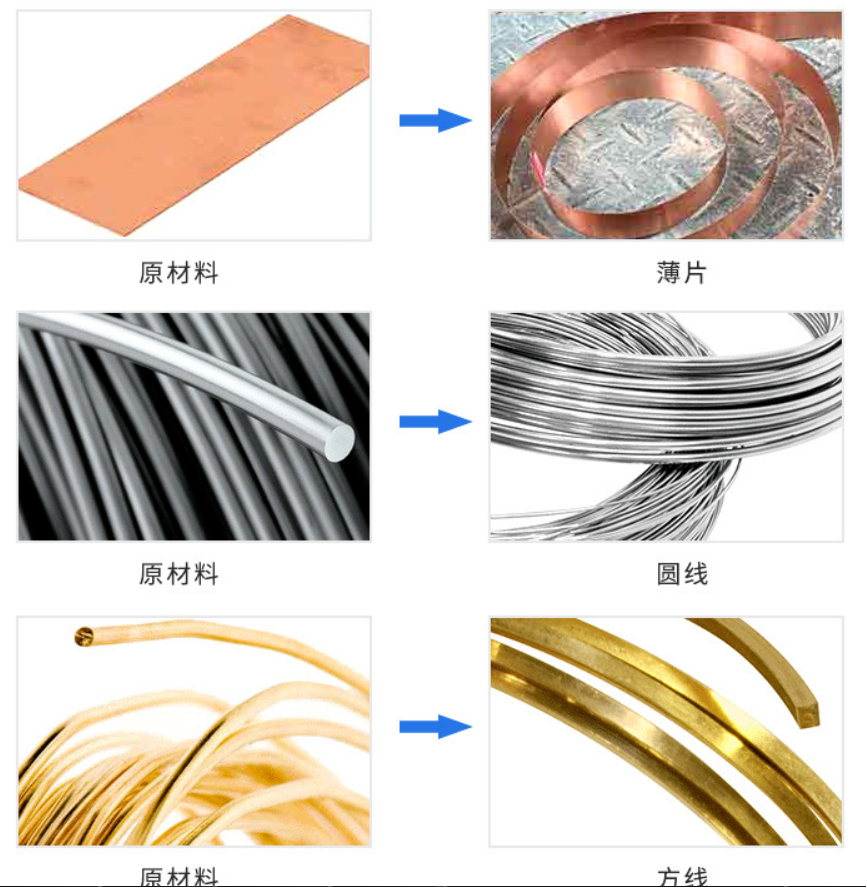

Hasung jewellery wire rolling mills machine, vailable in 8HP and 10HP models, is a top-tier solution for jewelry wire production. These wire rolling mills feature high-quality components and robust construction, ensuring durability and precision. With powerful motors, they efficiently roll metal wires to desired thicknesses, supporting various jewelry-making needs. In the field(s) of jewelry tools & equipment, our first class quality wire rolling machine in jewellery is widely used. Double head rolling mill is greater optional for users to have one side with wire rolling, one side with sheet rolling, or both sides with wire rolling, or sheets.

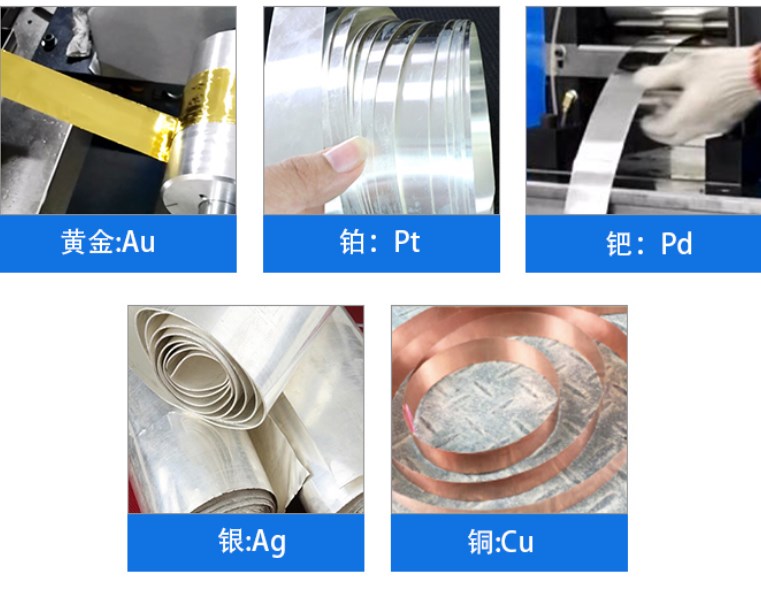

The Hasung jewelery wire rolling machines offer powerful performance, high-quality construction, adjustable rollers, and user-friendly design. They provide the precision and durability needed to produce high-quality jewelry components, ensuring every wire rolled meets the highest standards. This double head wire rolling mills series includes gold wire rolling machine, copper wire rolling machine, silver rolling machine and so on.

PRODUCT SPECIFICATIONS:

MODEL NO. | HS-D10HP | |

Optional for roller | both sides for all square wire or one side for sheet rolling, one side for wire rolling. (According to your request) | |

Brand Name | HASUNG | |

Voltage | 380V; 50Hz, 3 phases | |

Power | 7.5KW | |

Roller size | Diameter 120 × width 220mm | |

| Plain width | 65mm | |

| Wire size | 14mm-1mm | |

| Roller material | Cr12MoV, (DC53 is optional) | |

hardness | 60-61 ° | |

More function | automatic lubrication; gear drive | |

Dimensions | 1200*600*1450mm | |

Weight | approx. 900kg | |

Advantage | Rolling 14-1mm square wire; variable speed | |

After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service | |

Our confidence | Customers could compare our machine to other suppliers then you will see our machine will be your best choice. | |

Features At A Glance

1.Powerful Performance: Equipped with robust 8HP or 10HP motors, these rolling mills deliver high efficiency and reliability. The 8HP model operates at 1440 RPM, while the 10HP model runs at 1470 RPM, providing enhanced power for larger-scale operations.

2.High-Quality Construction: Built with durable materials like Cr12MoV rollers, these machines ensure long-lasting performance. The rollers are designed to withstand continuous use without wear or deformation, maintaining precision over time.

3.Adjustable Rollers: The jewelery wire rolling machine features adjustable rollers that allow users to set desired wire thicknesses and shapes easily. They can handle wire diameters ranging from 0.1mm to 5mm, making them versatile for various jewelry applications.

4.User-Friendly Design: Intuitive control panels enable quick and easy adjustments. The sturdy frame and compact design make these wire rolling machines suitable for both small workshops and larger production facilities.

5.Versatility: Compatible with a variety of metals used in jewelry making, including gold, silver, copper, and their alloys. This ensures the double head wire rolling mills can produce a wide range of jewelry components, from delicate chains to thicker wire forms.

Application:

1.Jewelry Production: Ideal for creating a wide range of jewelry components, including chains, rings, and bracelets. The adjustable rollers allow for precise wire thickness adjustments, enabling the production of delicate and intricate pieces.

2.Metalworking: Suitable for rolling various metals like gold, silver, copper, and their alloys. The wire rolling machine's versatility supports different wire diameters, from 0.1mm to 5mm, making it a valuable tool for diverse metalworking needs.

3.Custom Jewelry Design: Enables artisans to create custom wire designs for unique jewelry pieces. The ability to adjust wire thickness and shape allows for the production of bespoke components that meet specific design requirements.

4.Industrial Use: The robust construction and powerful motors make it suitable for industrial-scale jewelry production. The 8HP and 10HP models offer high efficiency and reliability, ideal for continuous operation in large workshops.

casting equipment, especially for high tech vacuum and high vacuum casting machines.

A: Two years warranty.

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115