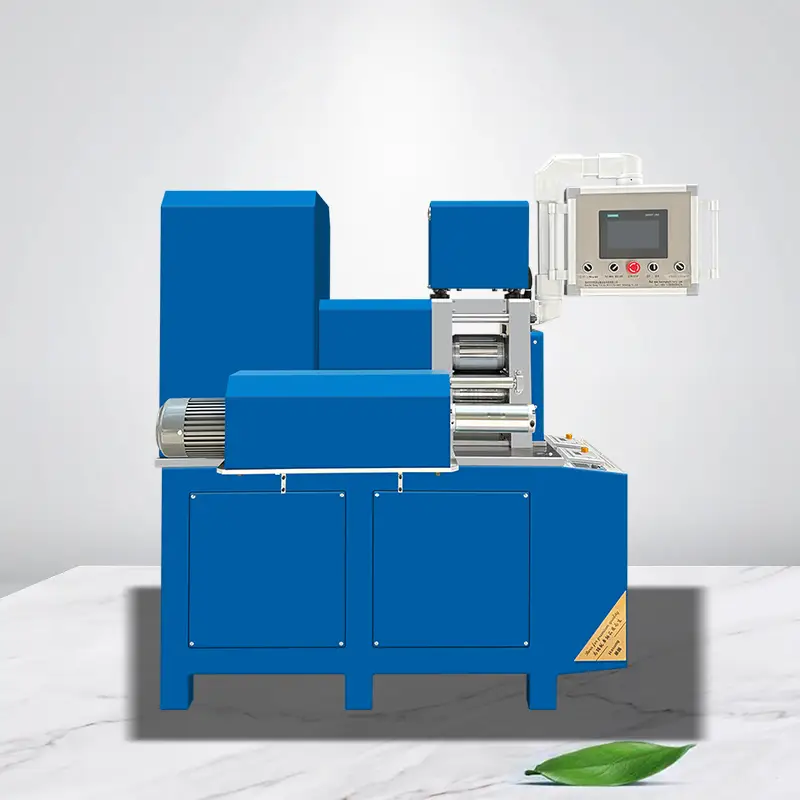

20HP Ultra-precision Numerical Control Hot Rolling Mill for gold silver alloys

20HP ultra-precision numerical control hot rolling mill, The equipment provided by the seller

is a complete and brand new set of equipment, including but not limited to:

I. Scope of supply:

1. Sheet rolling mill Body: 1 set

2. Cooling system: 1 set

3. Electronic Control System: 1 set.

4. Preheating system: 1 set

Model No.: HS-H20HP

II. Technical specifications:

(1) Material: Gold-Tin, tin bismuth and other alloys

(2) material thickness: ≤30mm

Finished product

(1) finished product thickness: ≥0.2 mm

(2) retractable drum, diameter: φ150 mm

3. Other parameters:

(1) roller temperature: ≤300 ° C

(2) roller, line speed: ≤9.5 mm/min

(3) motor power: 15KW

(4) roller downforce mode: servo numerical control

(5) roller downforce regulation mode: CNC downforce, all setting adjustable, single

adjustable,

(6) roll down adjustment accuracy: 0.001 mm

(7) Machine size (about) : 1800X 880x 1990mm

III. Equipment Specifications

1. Strip rolling system, is the strip hot rolling, after multi-pass rolling, to achieve the

required thickness. The lower roller is fixed and the upper roller is adjusted. The upper roller

adopts numerical control, adjustment, can be monotonous, also can adjust, adjustment

precision is 0.001 mm.

(1) Hot Roll: 2 rolls size: φ200x 250mm,

material: H 13,

hardness: HRC 63-65,

Roller width: 180mm,

Roller effective width: 110mm,

temperature: ≤300 ° C

(2) motor: 1 pcs

(3) reducer: 1 pcs

(4) temperature sensor: 2 pcs

(5) servomotors: 2 pcs

(6) lifting gear reducer: 2 set

2. Cooling system: for bearing sleeve and gantry, cooling

(1) piping system: 1 set

(2) Oil Cooler: 1 set

(3) water flow switch: 1 pcs

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115