Ziziphi iingenelo zokusebenzisa i-vacuum induction yokunyibilikisa iziko kwiialloys zesinyithi ezixabisekileyo?

Isihloko: Izinto ezilungileyo zokusebenzisa i-vacuum induction yokunyibilikisa iziko lokunyibilikisa ialloys zentsimbi exabisekileyo

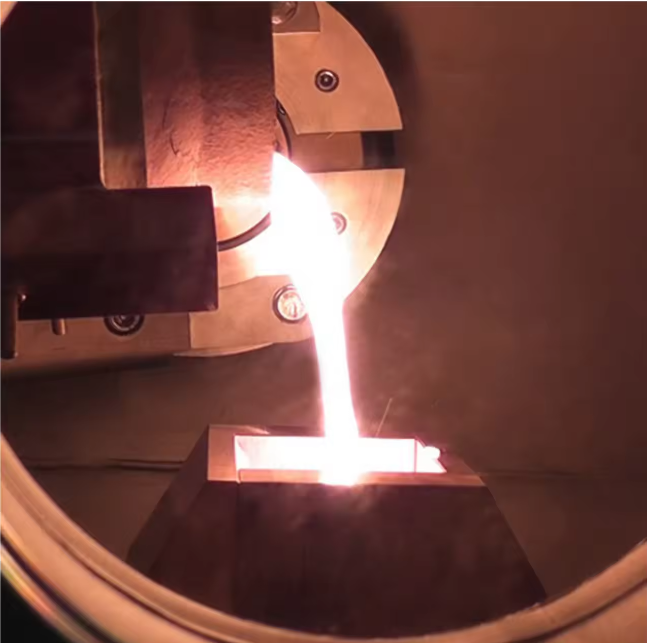

Zininzi iingenelo zokusebenzisa iziko lokunyibilikisa ivacuum induction melting (VIM) xa uvelisa ialloys zentsimbi exabisekileyo. Ubuchwephesha obuphezulu bubonelela ngendawo elawulwayo yokunyibilika kunye nokusulungekiswa kweentsimbi ezixabisekileyo, ukuvelisa i-alloys yeprimiyamu eneempawu eziphuculweyo. Kule bhlog, siza kuphonononga iingenelo zokusebenzisa i-vacuum induction melting furnace ukuvelisa ialloys zentsimbi exabisekileyo kunye nendlela enokunceda ngayo ukuvelisa izinto zokusebenza eziphezulu.

Enye yeenzuzo eziphambili zokusebenzisa i-vacuum induction melting ye-alloys yentsimbi exabisekileyo kukukwazi ukufezekisa ubunyulu obuphezulu. Ubume be-vacuum buthintela ukungcoliswa kweegesi kunye nokungcola, okukhokelela ekucocekeni okugqwesileyo kweekhemikhali ze-alloy. Olu coceko lubalulekile kwizicelo kumashishini afana ne-aerospace, unyango kunye nobucwebe, apho umgangatho kunye nokunyaniseka kwe-alloys yensimbi exabisekileyo kubaluleke kakhulu. Ukongezelela, umoya olawulwayo wesithando somlilo we-VIM uvumela ukubunjwa kwe-alloy echanekileyo, ukuqinisekisa ukuhambelana kwemveliso yokugqibela kunye nokuthembeka.

Ukongeza, ukusetyenziswa kwe-vacuum induction melting furnaces ivumela ukuveliswa kwee-alloys ezifanayo kunye nezihlakazekileyo. Ukuhanjiswa okulinganayo kwezinto ezixutywayo kuyo yonke isinyithi esinyibilikisiweyo kubalulekile ekufezekiseni izinto ezifunekayo zomatshini kunye neekhemikhali zemveliso yokugqibela. Inkqubo ye-VIM iququzelela ukuxuba ngokucokisekileyo kwamacandelo e-alloy, okubangela ukuba i-microstructure ingabikho ukuhlukana kunye neziphene. Olu lawulo lokubunjwa kwe-alloy kunye ne-microstructure inceda ukuvelisa amandla aphezulu, i-corrosion-resistant kunye ne-thermal stable metal exabisekileyo.

Ukongeza kumgangatho ophezulu wee-alloys eziveliswayo, ukusebenzisa i-vacuum induction melting furnace yenza inkqubo yokuvelisa isebenze ngakumbi kwaye ingabizi. Ulawulo oluchanekileyo lweemeko zokunyibilika kunye nokusulungekiswa kunciphisa inkcitho yezinto eziphathekayo kunye nokusetyenziswa kwamandla. Itekhnoloji ye-VIM ikwavumela ukunyibilika ngokukhawuleza kunye namazinga okuqinisa, okwandisa imveliso kunye nokunciphisa ixesha lokucubungula. Ngenxa yoko, abavelisi banokwandisa iinkqubo zabo zokuvelisa kunye nokunciphisa iindleko zokusebenza ngelixa behambisa i-alloys yentsimbi exabisekileyo esebenza kakhulu ukuhlangabezana neemfuno zamashishini ahlukeneyo.

Enye inzuzo yokusebenzisa i-vacuum induction melting ye-alloys yentsimbi exabisekileyo kukukwazi ukuhlalisa uluhlu olubanzi lweengxube ze-alloy kunye nobushushu obunyibilikayo. Nokuba yigolide, isilivere, iplatinam okanye ezinye iintsimbi ezixabisekileyo, itekhnoloji ye-VIM inokusingatha izinto ezahlukeneyo ze-alloying kwaye ifezekise ngokuchanekileyo indawo yokunyibilika efunekayo. Oku kuguquguquka kuvumela ukuveliswa kwee-alloys zesiko ezilungiselelwe izicelo ezithile, ukubonelela abavelisi ngeendlela ezahlukeneyo zokuhlangabezana neemfuno zeemarike ezahlukeneyo. Nokuba zizityalo zonyango, izixhobo ze-elektroniki okanye ubucwebe obunqabileyo, i-VIM Furnaces inokubonelela ngee-alloys ezineempawu ezilungiselelwe ukuhlangabezana neemfuno ezingqongqo zamashishini ahlukeneyo.

Ukongeza, ukusetyenziswa kwe-vacuum induction melting furnaces kunegalelo ekuzinzeni kwendalo ngokunciphisa ukukhutshwa kunye nokuveliswa kwenkunkuma. Inkqubo yeteknoloji ye-VIM evaliweyo inqanda iigesi ezinobungozi kunye ne-particle ukuba ikhutshwe emoyeni ngexesha lokunyibilika kunye nokucocwa. Ukongeza, ukusetyenziswa ngokufanelekileyo kwamandla kunye nezinto ezikrwada kwiziko le-VIM kuyahambelana neendlela ezizinzileyo zokwenziwa kunye nokunciphisa indawo engqongileyo yemveliso yentsimbi exabisekileyo. Njengoko ingqwalasela yehlabathi ekuzinzeni kunye nezenzo zokuvelisa ezinoxanduva ziqhubeka zikhula, iteknoloji ye-VIM inikezela ngesisombululo esisebenzayo esihlangabezana neemfuno zeshishini ngelixa sinciphisa impembelelo yokusingqongileyo.

Isishwankathelo, izibonelelo zokusebenzisa i-vacuum induction melting furnace ukunyibilikisa ialloys zentsimbi exabisekileyo ayinakuphikiswa. Ukususela ekufezekiseni ukucoceka okuphezulu kunye nokufana nokuphucula ukusebenza kakuhle kunye nokuzinza, iteknoloji ye-VIM idlala indima ebalulekileyo ekuveliseni i-alloys ephezulu yokusebenza kwizicelo ezahlukeneyo. Njengoko amashishini aqhubeka efuna umgangatho ophezulu kunye neepropati ezenziwe ngokwezifiso kwii-alloys zetsimbi ezixabisekileyo, ii-VIM furnaces zisisombululo esithembekileyo nesiphezulu sokuhlangabezana nezi mfuno. Itekhnoloji ye-VIM ihlala ilitye lembombo lokuqamba izinto ezintsha kwimveliso yealloy yentsimbi exabisekileyo ngenxa yokukwazi ukuhambisa iialloyi ezikumgangatho ophezulu ngokuqhubekayo ngelixa kuncitshiswa impembelelo yokusingqongileyo.

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjineli boomatshini ekwimazantsi eTshayina, kwisixeko esihle nesikhula ngokukhawuleza kwezoqoqosho, iShenzhen. Le nkampani yinkokheli kwezobuchwepheshe kwicandelo lezixhobo zokufudumeza nokuthunga izixhobo zesinyithi esixabisekileyo kunye neshishini lezinto ezintsha.

Ulwazi lwethu olomeleleyo kubuchwepheshe bokuphosa i-vacuum lusenza sikwazi ukunceda abathengi bemizi-mveliso ukuphosa intsimbi exutywe kakhulu, i-platinum-rhodium alloy efunekayo kakhulu, igolide nesilivere, njl.

Umnxeba: +86 17898439424

I-imeyile:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Idilesi: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115