Hasung ƙwararren masani ne kan sarrafa injinan siminti da narke ƙarfe masu daraja tun daga shekarar 2014.

Menene kayan aikin hako zinare?

Yadda za a cire zinariya daga allon kewayawa?

Hadakar kayan aiki don hakar zinariya: babban electroplating cikakken kayan aiki / zinariya da azurfa electrolysis dawo da inji, samun iska majalisar, ruwa zuba inji, gilashin dauki kwalban, aqua regia tacewa mota, Ph atomatik dosing tsarin, raguwa da tacewa hadedde inji, soso zinariya tace ganga, PP rage dauki tanki, neutralization tank, biyu Layer dauki tanki ga narkakken zinariya, sharar gida magani da dai sauransu.

Farashin na'urorin tace zinare na allunan da'ira suna da girma sosai, daga dubun dubatar zuwa ɗaruruwan dubbai. Farashin yana tasiri da abubuwa kamar girman samfurin kayan aiki, kayan masana'anta, inganci, ƙirar tsari, da girman fitarwa, kuma yana iya canzawa sama da ƙasa. Yana da wuya a ƙayyade ƙayyadadden farashi, kuma masana'antun za su iya ba da ƙayyadaddun ƙididdiga kawai bayan ƙayyade bukatun ku da takamaiman yanayin aiki.

An fi amfani da kayan aikin gyaran ƙarfe masu daraja don fitar da karafa masu daraja kamar zinariya, azurfa, platinum, palladium, da dai sauransu. A halin yanzu, Fuxin Environmental Refining yana amfani da hanyoyin kamar tsarkakewar chlorination, tsarkakewar ruwa regia, tsarkakewa na electrolysis, tsarkakewar chloramine, da dai sauransu.

Kayan aiki da aka saba amfani da su sun haɗa da: babban na'ura mai amfani da wutar lantarki cikakke / zinariya da na'urar lantarki ta lantarki, na'ura mai ba da iska, injin ruwa, na'ura mai ɗaukar gilashin ruwa, motar aqua regia tace, tsarin dosing na atomatik, ragewa da tace haɗaɗɗen injin, soso gwal tace ganga, PP rage dauki tanki, neutralization tank, biyu Layer dauki kwalban ga narkewa zinariya, da kuma sharar gida magani kayan aiki.

Menene hanyoyin hako karafa masu daraja daga zinari?

Zinariya samfuri ne na halitta wanda ba za a iya haɗa shi ta hanyar wucin gadi ba, kuma an raba shi zuwa ɗanyen zinariya da dafaffen zinariya. Zinare da ya kai tsaftar inganci bayan tsarkakewa ana kiransa gwal zalla, yawanci yana nufin zinari tare da tarar sama da 99.6%. Zinare da aka tsarkake gabaɗaya yana da tsafta, kuma wasu ana iya amfani da su kai tsaye don samar da masana'antu.

1. Yadda Ake Tace Zinare

Guda guda ɗaya ya dace don sarrafa taman ƙarfe na gwal na gwal da matsakaici. Ana ciyar da takin da aka niƙa a cikin injin niƙa, a niƙa shi cikin slurry, sannan ya shiga cikin iyo. Haɗe-haɗewar ruwan mercury ya dace don sarrafa gwal na halitta tare da ƙaƙƙarfan nau'in ƙwayar ƙwayar cuta, an adana shi a cikin pyrite da sauran nau'ikan sulfide. Ba kamar tuwo guda ɗaya ba, ƙara farantin mercury bayan niƙa don dawo da gwal na iya samun saurin dawowa na 30-45%. Mai ɗaukar bel a cikin farfajiyar wutsiya; Yashi mai yashi wanda bai fi girman ramin sieve ba ana ciyar da shi cikin injin jigging madauwari mataki na 1-3 ta hanyar mahaɗar jama'a, kuma mai da hankali yana gudana cikin tebur mai girgiza ta na'urar jigin mataki 3 don ƙaƙƙarfan, mai kyau, da zaɓe don samar da tama mai kyau. Ana amfani da wannan hanyar sau da yawa don ma'adinan yashi, kuma ana iya shafa tama mai kyau da aka niƙa.

2. Gabatarwa Hanyar Cire Zinariya ta hanyar hada Mercury da Tsarkake Zinare

Wannan hakika tsohuwar hanyar tsarkakewa ce ta zinare, idan dai kuna da haƙuri, zaku iya ambaton babban tsarki. Takamammen hanyoyin sune kamar haka:

Ruwan Zinari+Mercury+, yana ci gaba da niƙa har sai babu ɓangarorin gwal, kuma zinare da mercury suna zama mahadi na tsaka-tsaki. A nika a hada sulfur foda da zinariya da aka yi kama da mercury, da zafi da kuma ƙone shi a cikin iska. A wannan lokacin, ragowar mercury ya ƙafe, kuma ƙananan karafa sun fara samar da sulfide na karfe, wanda daga baya ya zama karfe oxides. Maimaita aikin da ke sama sau da yawa kuma ƙara borax don narke cikin gwal. Tushen ƙarfe oxides suna amsawa tare da borax don samar da ƙananan abubuwa masu narkewa, waɗanda ke iyo akan saman saman ruwan. Zinariya mai tsabta za ta yi amfani da wannan hanya a ƙasa don hana gubar tururin mercury.

3. Gabatarwa Tsarin Tsabtace Zinare Rigar don Cire Zinare

Tsarin tsarkakewar zinari mai jika yana ɗaukar hanyar narkar da gwal a cikin aqua regia da ƙara wakili mai ragewa don rage gwal, ko kuma idan ana amfani da wakili mai rufe fuska zuwa hadaddun abubuwa masu shiga tsakani, sannan a cire shi tare da ainihin wakili ko cirewa. Wannan ƙirƙira ta karya ta hanyoyin gargajiya kamar narke mai zafi da sauran matakai masu sauƙi don samun zinari mai inganci. Idan aka kwatanta da fasahohin da ake da su, abin da aka ƙirƙira na yanzu yana da halaye na tsabtataccen samfurin, rage farashin samarwa, da sauƙi da matakai masu amfani. Wata hanyar kuma ita ce dakakken aikin gwal, wanda ya hada da sanya danyen zinare a cikin akwati, sannan a zuba shi a cikin sabuwar aqua regia da aka shirya don nutsar da danyen gwal, sannan a dumama shi ya narke na tsawon mintuna 15-25. Idan danyen zinaren bai narkar da shi gaba daya ba, za a iya kara aqua regia don narkar da shi akai-akai har sai ya narke gaba daya.

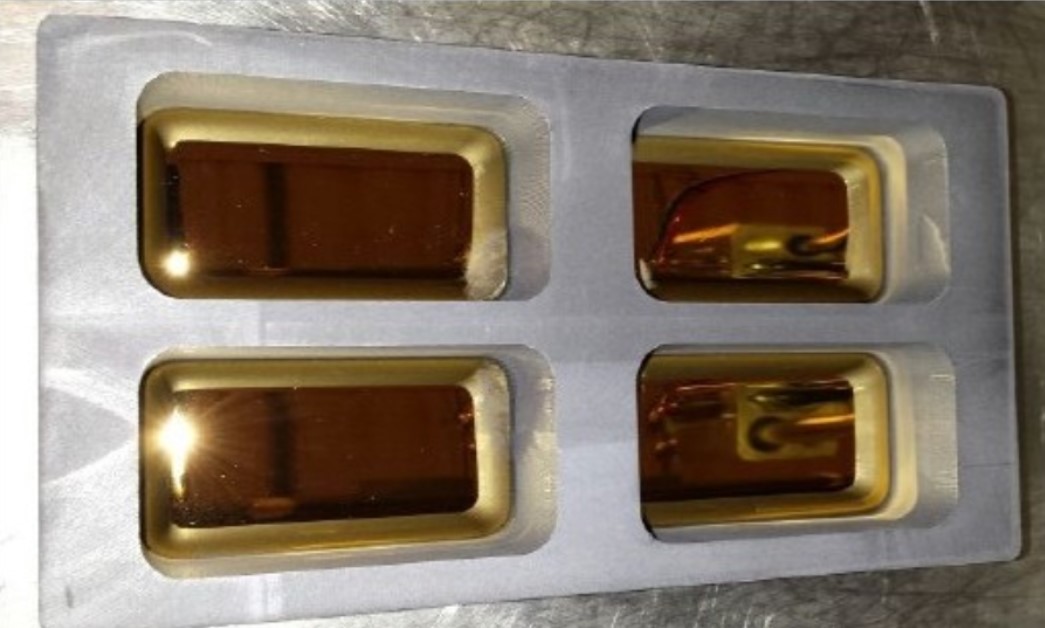

A ƙarshe, yi amfani da injunan simintin ƙarfe na Hasung masu daraja don kera sandunan zinare masu ƙyalƙyali, na'ura ce ta granulating

Lambar waya: +86 17898439424

Imel: sales@hasungmachinery.comda

WhatsApp: 0086 17898439424

Adireshi: No.11, Titin 1st Jinyuan, Al'ummar Heao, Titin Yuanshan, Gundumar Longgang, ShenZhen, China 518115