The Role of 12-Die Wire Drawing Machines in Necklace Production Lines

Necklace manufacturing is a delicate and intricate process involving multiple stages, such as metal smelting, wire drawing, weaving, and polishing. Among these, metal wire drawing is one of the foundational steps, directly impacting the quality and aesthetics of the final product. The 12-die wire drawing machine, as a highly efficient metal processing device, plays a crucial role in necklace production lines. This article provides a detailed overview of the working principles, technical advantages, and specific applications of 12-die wire drawing machines in necklace manufacturing.

1. Basic Structure and Working Principle of the 12-Die Wire Drawing Machine

(1)Machine Structure

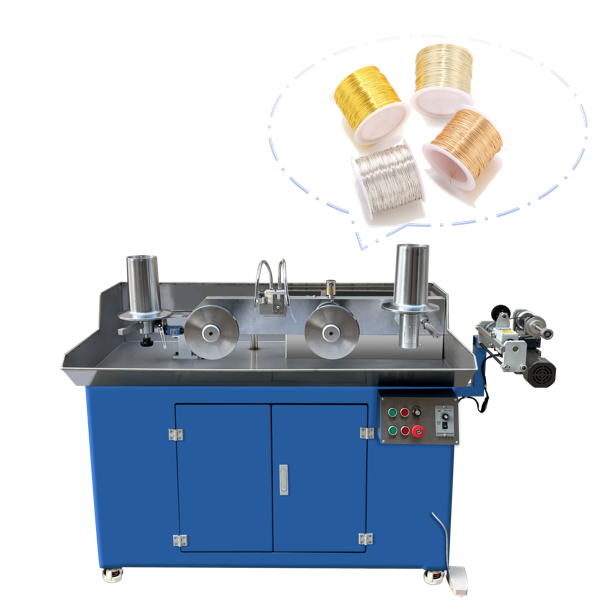

The 12-die wire drawing machine is a multi-stage wire processing device primarily composed of the following core components:

Unwinding Stand: Holds the raw metal wire (e.g., gold, silver, copper).

Wire Drawing Die Set: Contains 12 dies with progressively smaller apertures to gradually reduce the wire diameter.

Tension Control System: Ensures uniform force distribution during drawing to prevent breakage or deformation.

Rewinding Unit: Coils the finished wire neatly for subsequent processing.

(2) Working Principle

The 12-die wire drawing machine employs a multi-pass continuous drawing process. The metal wire passes sequentially through 12 dies of decreasing size, undergoing gradual diameter reduction under tensile force until the desired fineness is achieved. This method ensures high efficiency and stability, making it suitable for mass production.

2. Advantages of 12-Die Wire Drawing Machines in Necklace Manufacturing

(1)Enhanced Production Efficiency

Unlike single-die machines that require frequent die changes, the 12-die machine completes multiple drawing stages in one pass, significantly reducing processing time and improving overall production efficiency.

(2)Superior Wire Quality

The multi-stage drawing process minimizes internal metal stress, preventing surface cracks or burrs, thereby enhancing the durability and finish of necklaces.

(3)Compatibility with Various Metals

The machine supports drawing precious metals such as gold, silver, copper, and platinum, catering to diverse necklace material requirements.

(4)Energy Efficiency

Compared to single-die machines, the 12-die system reduces frequent start-stop cycles, lowering energy consumption and aligning with modern sustainable manufacturing practices.

3. Applications in Necklace Production Lines

(1) Fine Chain Link Production

Necklace chains often require ultra-thin wires for weaving. The 12-die machine can stably produce wires as fine as 0.1mm, ensuring smooth and delicate chain links.

(2)Support for Custom Designs

By adjusting die configurations, the machine produces wires of varying diameters, meeting designers' needs for customized thickness and flexibility.

(3) Integration with Downstream Equipment

The drawn wires can be directly fed into twisting machines, braiding machines, or other equipment, forming a seamless automated production line.

4. Future Development Trends

As jewelry manufacturing demands higher precision and efficiency, 12-die wire drawing machines are evolving toward smarter and more automated solutions, such as:

Intelligent Control Systems: Real-time monitoring via sensors to auto-adjust parameters.

High-Precision Dies: Nano-coating technology to extend die lifespan and improve accuracy.

Integration with 3D Printing: Enabling more flexible customization in necklace production.

Conclusion

The 12-die wire drawing machine, with its efficiency, stability, and versatility, has become an indispensable component of necklace production lines. It not only boosts productivity and product quality but also unlocks new possibilities for bespoke designs. With ongoing technological advancements, this machine will continue to drive the jewelry industry toward higher standards of excellence.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115