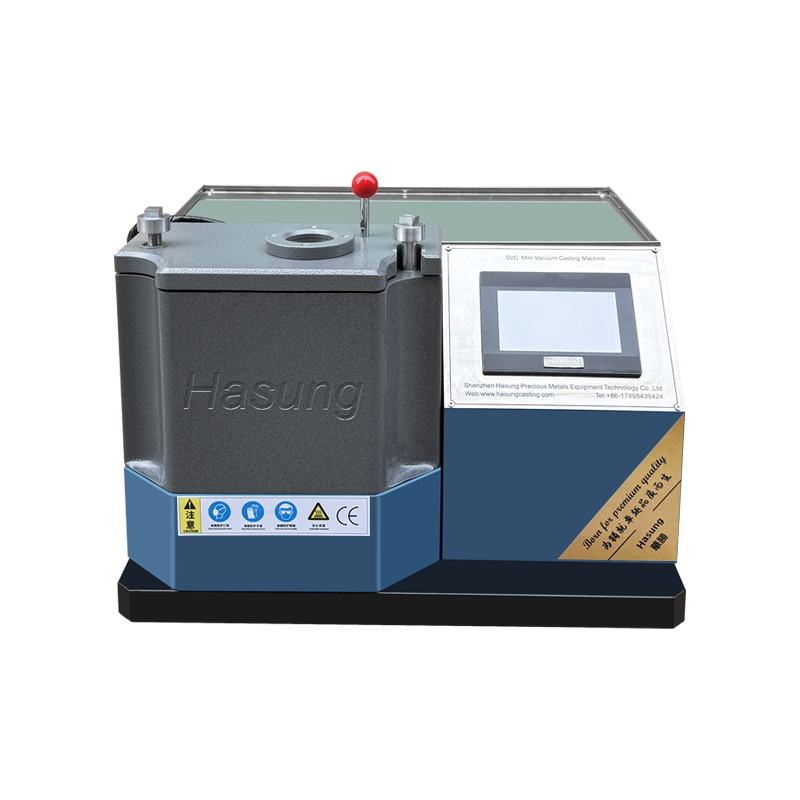

Hasung inyanzvi yekugadzira michina yekukanda nekunyungudutsa simbi dzinokosha kubvira muna 2014.

Michina midiki yekukanda zvishongo ingagadzira zvitaera zvakaomarara here?

Mumusika wemazuva ano wevatengi wezvishongo unoteedzera munhu uye dhizaini yakasarudzika, zvitaera zvakaoma uye zvakanakisa zviri kuwedzera kufarirwa. Semubatsiri ane simba kune akawanda mhizha yezvishongo uye madiki studio, kugona kwemashini madiki ekukanda zvishongo kugadzira nemazvo maitiro akaomarara kwave kutarisisa muindasitiri. Izvi hazvisi chete zvine chekuita nekuratidzwa kwakakwana kweiyo musiki dhizaini pfungwa, asi zvakare inokanganisa kukwikwidza kwechigadzirwa mumusika.

Kushanda musimboti uye tekinoroji maitiro ediki madiki ekukanda muchina

Zvishongo zvidiki zvekukanda michina inowanzo shandisa induction kupisa tekinoroji. Tichitora diki yepakati frequency yekunyungudutsa choto semuenzaniso, iyo yepakati frequency magetsi emagetsi anoburitsa epakati frequency AC simba kubva kumazana akati wandei hertz kusvika kuzviuru zvehertz. Iyo yazvino inopfuura nepakati induction coil yakagadzirwa nemhangura kana aluminium, ichigadzira alternating magnetic field. Kana iyo simbi inoiswa mucrucible iri mune ino magineti, induced yazvino inogadzirwa nekuda kweeddy yazvino maitiro. Ikozvino inoyerera mukati mesimbi uye inogadzira kupisa nekuda kwekupikisa, zvichiita kuti simbi ikurumidze kupisa kusvika yanyunguduka.

Iyi nzira yekudziya ine hunyanzvi hwepamusoro uye inogona kukurumidza kupisa simbi kusvika pakunyungudika kwayo, ichivandudza kugadzirwa kwekugadzira. Uyezve, nekunyatso gadzirisa zvigadziro zvekupisa, kupisa kweyunifomu yesimbi zvinhu zvinogona kuwanikwa, kuderedza njodzi yekupisa kwenzvimbo kana kusakwana kupisa.

Mimwe michina midiki yekukanda zvishongo zvepamberi inoshongedzerwa nehungwaru kudzora masisitimu, akadai seSiemens PLC control masisitimu, ayo asingangoita kuti oparesheni ive yakachengeteka uye nyore, asi zvakare kudzora nemazvo tembiricha kuverenga nekurongeka kwe ± 2 ° C. Mukukanda, mimwe michina ine vacuum pressurization basa, iyo inopinza inert gasi panguva yekunyunguduka, inodzivirira, inoparadzanisa oxijeni pamusoro pesimbi inonyunguduka, inodzivirira uye inoparadzanisa oxing pamusoro pesimbi inonyungudika. castings isina pores uye shrinkage, ine high density.

Zvinhu zvakakosha zvinokanganisa kurongeka kwemashini madiki ekukanda zvishongo

(1) Mold mhando uye kuchinjika

Mould chinhu chakakosha pakuona kurongeka kwemasitaera ekukanda. Kune masitayipi akaomarara, dhizaini uye kugadzirwa kwe molds kunofanirwa kunge kwakanyatso kurongeka. Yakanyanya kurongeka 3D yekudhinda mold kana wakisi yakarasika yekukanda mold inogona kudzokorora zvinhu zvakaomarara, asi iyo yekupisa yekuwedzera coefficient ye mold zvinhu inoda kuenderana nesimbi yekukanda. Kana mutsauko mukupisa kwekuwedzera kweiyo coefficient yakakura kwazvo, panguva yekudziya uye kutonhora maitiro, iyo shrinkage kana kuwedzera kwe mold uye kukanda kunenge kusingaenderane, izvo zvinozotungamira kune dimensional kutsauka uye kudzima ruzivo rwekukanda. Semuyenzaniso, kana uchikanda zvishongo zvine makomba makomba mapatani, kunyangwe kushomeka kushoma mu mold kunogona kuita kuti mipendero yemapateni isave pachena kana kutyoka.

(2) Hunhu hweSimbi Zvishandiso

The flowability, shrinkage rate, uye humwe hunhu hwemhando dzakasiyana dzesimbi zvine chekuita kwakakura pakukanda chaiko. Simbi dzakakosha dzakaita segoridhe nesirivheri dzine mvura yakanaka uye dzinogona kuzadza mhango dzakaomarara mu molds zvakanaka, asi shrinkage yavo yakakwira zvakare. Munguva yekutonhodza uye kusimba, huwandu hwesimbi hunoderera. Kana iyo inofungidzirwa huwandu hwe shrinkage isiri iyo chaiyo, ichaita kuti saizi yekukanda ive diki pane inotarisirwa. Zvimwe zviwanikwa zvealloy, kunyangwe misiyano mishoma mukuumbwa, inogona kushandura zvimiro zvavo zvemuviri uye kukanganisa maitiro ekukanda. Semuenzaniso, chikamu chakati chemhangura zinc alloy chinoshandiswa kukanda yakaoma yekare maitiro akavezwa zvishongo. Kana iyo zinc yemukati mune alloy ichichinja, inogona kukonzera shanduko mukuyerera kwezvinhu, zvichikonzera kuzadzwa kusina kukwana kwezvikamu zvakavezwa.

(3) Kudzora kweCasting process Parameters

Kudzora kwakaringana kwekukanda maparamendi akadai setembiricha, kumhanya kwekukanda, uye nguva yekutonhora kwakakosha. Kana tembiricha yakakwira zvakanyanya, iyo simbi yesimbi inogona kuwedzera oxidize uye ine yakasimba fluidity, iyo inogona kugeza pamusoro pe mold, kukuvadza ruzivo rwe mold, uye kuunza kushushikana kukuru panguva yekutonhora kwekukanda, zvichiita kuti deformation kana kuputika; Kana tembiricha yakadzikira, kuyerera kwesimbi yemvura kwakashata uye haigone kuzadza zvachose mold.

Kana iyo yekukanda kumhanya ichimhanya zvakanyanya, mhepo iri mu mold cavity haigone kuburitswa nenguva, iyo inogona nyore kugadzira pores mukati mekukanda; Kunonoka kukanda kumhanya uye kutonhora kusati kwasvika kwesimbi yakanyungudutswa panguva yekuyerera kunogona kukonzera kusakwana kuzadza. Kana nguva yekutonhora isina kunyatsodzorwa, chimiro chemukati chekukanda chinenge chisina kuenzana, icho chinozokanganisawo kurongeka kwedimensional uye kunaka kwepamusoro.

Inoshanda kesi kesi yemuchina diki wekukanda zvishongo mune yakaoma maitiro ekugadzira

Mune mamwe masitudiyo madiki ezvishongo, tekinoroji yepamberi ine michina midiki yekukanda zvishongo inoshandiswa zvinobudirira kugadzira zvinoshamisa zvitaera zvakaomarara zvezvishongo. Semuyenzaniso, pendant yesirivha yakafemerwa nemapfundo ekare eCeltic, ane mitsetse yakarukwa uye mapatani akaomarara anoratidzwa nemazvo kuburikidza nediki diki rekumanikidza kukanda muchina. Iyo vacuum nharaunda yemuchina wekukanda inonyatso kudzivirira oxidation yesirivheri yemvura, uye chaiyo tembiricha yekudzora inova nechokwadi chekuti sirivheri mvura inoyerera nemazvo, ichizadza zvakaenzana zvese zve mold. Chigadzirwa chekupedzisira chine mitsetse yakatsetseka uye mapatani akajeka, anenge akafanana nedhizaini yekugadzira.

Zvisinei, kunewo zviitiko zvezvinetso uye kukanganisa. Musiki akaedza kukanda zvishongo zvegoridhe zvine machira akawanda zvine zvikamu zvinotenderera. Pasinei nekushandisa yakakwirira-chaiyo molds, chigadzirwa chekupedzisira chakaratidza kuderera kuduku nekuda kwepamusoro shrinkage rate yegoridhe uye kuoma kwekunetseka kwekuchinja kwemaitiro akawanda-layered panguva yekutonhora. Kukodzera kwezvikamu zvinotenderera kwakanga kusina kunyatsokwana, izvo zvakakanganisa maitiro ose. Izvi zvinoratidza kuti michina midiki yekukanda zvishongo ichiri kuda kuenderera mberi nekuongorora optimization uye tekinoroji kuvandudza kana yakatarisana nemaitiro akaomarara anoda kurongeka kwepamusoro.

Zvishongo zvidiki zvekukanda michina ine humwe hunyanzvi mukugadzira zvitaera zvakaomarara, uye kuita kwavo kunoramba kuchivandudzika nekufambira mberi kwetekinoroji. Kuburikidza nemhando yepamusoro mold, zvinhu zvinowirirana, uye chaiyo process parameter control, zvinokwanisika kuwana emhando yepamusoro kukanda kweakawanda akaomarara dhizaini. Nekudaro, hazvigone kurambwa kuti pachine zvipimo kana uchibata nezvitaera zvinoda zvakanyanya kuomarara zvimiro uye kunyatso hunyanzvi.

Mune ramangwana, nekuvandudzwa kwakarongeka kwesainzi yemidziyo, tekinoroji yekugadzira mold, uye maitiro ekukanda, michina midiki yekukanda zvishongo inotarisirwa kuwana budiriro yakakura mumunda wekugadzira maitiro akaomarara, ichiunza mikana yakawanda yekugadzira zvishongo uye kubatsira indasitiri kusvika pakakwirira.

Unogona kutibata nesu nenzira dzinotevera:

Whatsapp: 008617898439424

Email:sales@hasungmachinery.com

Webhu: www.hasungmachinery.com www.hasungcasting.com

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ikambani yeinjiniya yemakanika iri kumaodzanyemba kweChina, muguta rakanaka uye riri kukura nekukurumidza muhupfumi, Shenzhen. Kambani iyi inotungamira muhunyanzvi hwetekinoroji munharaunda yemidziyo yekudziyisa nekukanda simbi dzinokosha neindasitiri yezvinhu zvitsva.

Ruzivo rwedu rwakasimba muhunyanzvi hwekukanda vacuum runotigonesawo kushandira vatengi vemaindasitiri kugadzira simbi ine musanganiswa wakawanda, platinum-rhodium alloy inodiwa ne musanganiswa wakawanda, goridhe nesirivha, nezvimwewo.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Kero: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115