Ngaba oomatshini abancinci bokuphosa izacholo bayakwazi ukwenza ngokuchanekileyo izitayile ezintsonkothileyo?

Kwintengiso yabathengi yanamhlanje yobucwebe obujonge ubuwena kunye noyilo olulodwa, izitayile ezintsonkothileyo nezigqwesileyo ziya zithandwa. Njengomncedisi onamandla kwiingcibi ezininzi zobucwebe kunye nezitudiyo ezincinci, ukukwazi koomatshini abancinci bokuphosa ubucwebe ukwenza ngokuchanekileyo izitayela ezintsonkothileyo ziye zaba ingqwalasela kwishishini. Oku akuhambelani kuphela nomboniso ogqibeleleyo wengqikelelo yoyilo lomdali, kodwa ikwachaphazela ukukhuphisana kwemveliso kwimarike.

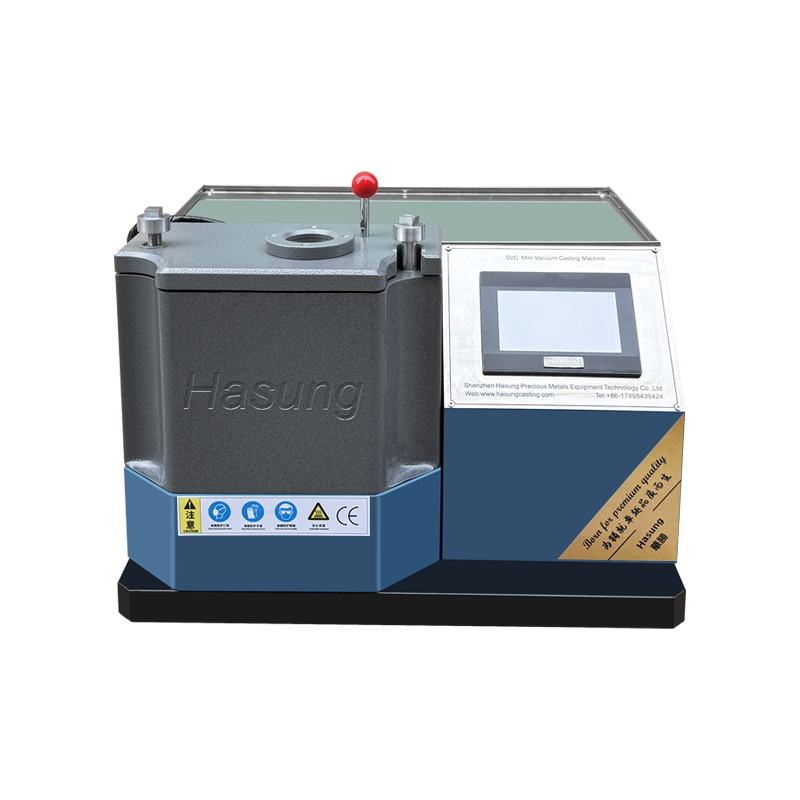

Umgaqo osebenzayo kunye neempawu zobugcisa zomatshini omncinci wokuphosa ubucwebe

Oomatshini abancinci bokuphosa izacholo bahlala besebenzisa itekhnoloji yokufudumeza induction. Ukuthatha iziko elincinci lokunyibilikisa eliphakathi njengomzekelo, unikezelo lwamandla ombane ophakathi lukhupha amandla aphakathi amaza e-AC ukusuka kumakhulu aliqela ehertz ukuya kumawaka aliqela ehertz. Ikhoyo ngoku idlula kwikhoyili ye-induction eyenziwe ngobhedu okanye i-aluminium, ivelisa indawo yamagnetic eguqukayo. Xa izinto zetsimbi ezibekwe kwi-crucible kule ntsimi yamagnetic, i-current induced iya kuveliswa ngenxa yesiphumo se-eddy yangoku. Ikhoyo ngoku iqukuqela ngaphakathi kwesinyithi kwaye ivelise ubushushu ngenxa yokuchasana, okubangela ukuba isinyithi sishushu ngokukhawuleza de sinyibilike.

Le ndlela yokufudumala inokusebenza okuphezulu kwaye inokukhawuleza ukutshisa isinyithi kwindawo yayo yokunyibilika, ukuphucula ukusebenza kakuhle kwemveliso. Ngaphezu koko, ngokulungelelanisa ngokuchanekileyo iiparamitha zokufudumeza, ukufudumeza okufanayo kwezinto zetsimbi kunokufezekiswa, ukunciphisa umngcipheko wokushisa kwendawo okanye ukufudumeza okwaneleyo.

Abanye oomatshini bokuphosa ubucwebe abancinci abaphambili nabo baxhotyiswe ngeenkqubo zokulawula ezikrelekrele, ezinjengeesistim zokulawula ze-Siemens PLC, ezingagcini nje ukwenza umsebenzi ukhuseleke kwaye ulunge ngakumbi, kodwa ulawule ngokuchanekileyo ukufundwa kobushushu ngokuchaneka kwe ± 2 ° C. Kwinkqubo yokuphosa, abanye oomatshini banomsebenzi woxinzelelo lwevacuum, ofaka igesi engasebenziyo ngexesha lokunyibilika, ukuthintela, ukuhlukanisa i-oxing ye-oxygen kumphezulu we-oxygen, ukuthintela, kunye nokulawula i-oxidi yentsimbi. ii-castings ezingenayo i-pores kunye ne-shrinkage, kunye nokuxinana okuphezulu.

Izinto eziphambili ezichaphazela ukuchaneka koomatshini abancinci bokuphosa ubucwebe

(1) Umgangatho wokungunda kunye nokuziqhelanisa

Umngundo ngumba obalulekileyo ekuqinisekiseni ukuchaneka kwezimbo zokuphosa. Kwizitayela ezintsonkothileyo, uyilo kunye nokuveliswa kwesikhunta kufuneka kuchaneke kakhulu. Ukuchaneka okuphezulu kokubumba kwe-3D yokushicilela okanye i-wax elahlekileyo yokubumba i-molds inokuphindaphinda iinkcukacha ezinzima, kodwa i-coefficient yokwandisa i-thermal ye-mold material idinga ukuhambelana nentsimbi yokuphosa. Ukuba umahluko kwi-coefficient yokwandisa i-thermal inkulu kakhulu, ngexesha lokufudumeza kunye nenkqubo yokupholisa, ukucutha okanye ukwandiswa kwesikhunta kunye nokuphosa kuya kuhambelana, okuya kubangela ukuphambuka kwe-dimensional kunye neenkcukacha eziphazamisayo zokuphosa. Umzekelo, xa uphosa ubucwebe obuneepateni ezintsonkothileyo, kwanokonakala okuncinci ekubumbeni kunokubangela ukuba imiphetho yeepateni ingacaci okanye iphuke.

(2) Iimpawu zeMathiriyeli yesinyithi

Ukuhamba, izinga lokuncipha, kunye nezinye iimpawu zezixhobo zetsimbi ezahlukeneyo zinempembelelo enkulu ekuphoseni ukuchaneka. Iintsimbi ezixabisekileyo ezifana negolide kunye nesilivere zinomanzi kwaye zinokuzalisa imingxuma entsonkothileyo kubumba kakuhle, kodwa izinga lokushwabana kwazo liphezulu. Ngethuba lokupholisa kunye nenkqubo yokuqinisa, umthamo wensimbi uyancipha. Ukuba ixabiso eliqikelelweyo lokucutheka alichanekanga, liya kubangela ukuba ubungakanani bokuphosa bube buncinci kunokuba bulindelwe. Ezinye izinto ze-alloy, kunye nokungafani okuncinci ekubunjweni, kunokutshintsha iimpawu zabo zomzimba kwaye kuchaphazele umphumo wokuphosa. Umzekelo, umlinganiselo othile we-alloy ye-zinc yobhedu isetyenziselwa ukuphosa ubucwebe obuqingqiweyo besitayile sakudala. Ukuba umxholo we-zinc kwi-alloy iyaguquguquka, inokubangela utshintsho kwizinto eziphathekayo, okukhokelela ekuzalisweni okungaphelelanga kweendawo eziqingqiweyo.

(3) Ukulawulwa kweeParamitha zeNkqubo yokuCasa

Ulawulo oluchanekileyo lweeparamitha zenkqubo yokuphosa ezifana nobushushu, isantya sokuphosa, kunye nexesha lokupholisa libalulekile. Ukuba iqondo lokushisa liphezulu kakhulu, i-metal liquid inokuthi i-oxidize ngokugqithiseleyo kwaye ibe ne-fluidity enamandla, enokuthi ihlambe ubuso besikhunta, yonakalise iinkcukacha ze-mold, kwaye ivelise uxinzelelo olubalulekileyo ngexesha lokupholisa ukuphosa, okukhokelela kwi-deformation okanye ukuqhekeka; Ukuba iqondo lokushisa liphantsi kakhulu, ukuhamba kolwelo lwetsimbi kubi kwaye akukwazi ukuzalisa ngokupheleleyo umgodi wokungunda.

Ukuba isantya sokuphosa sikhawuleza kakhulu, umoya kwi-mold cavity awukwazi ukukhutshwa ngexesha, elinokuthi lenze kalula iipores ngaphakathi kwe-casting; Isantya esicothayo sokuphosa kunye nokupholisa kwangaphambili kwesinyithi esinyibilikisiweyo ngexesha lenkqubo yokuhamba kunokubangela ukuzaliswa okunganeleyo. Ukuba ixesha lokupholisa alilawulwa ngokufanelekileyo, isakhiwo sangaphakathi sokuphosa siya kungalingani, okuya kuchaphazela ukuchaneka kwe-dimensional kunye nomgangatho ophezulu.

Ityala elisebenzayo lomatshini omncinci wokuphosa ubucwebe kwindalo yesitayile esintsonkothileyo

Kwezinye izitudiyo ezincinci zobucwebe, itekhnoloji ephezulu exhotyiswe ngoomatshini abancinci bokuphosa ubucwebe basetyenziswa ngempumelelo ukwenza izitayile ezintsonkothileyo zobucwebe. Umzekelo, ipendant yesilivere ephefumlelwe ngamaqhina amandulo eCeltic, enemigca ephothiweyo kunye neepateni ezintsonkothileyo ezivezwa ngokuchanekileyo ngomatshini omncinci wokuphosa uxinzelelo. Imeko ye-vacuum yomatshini wokuphosa ithintela ngokufanelekileyo i-oxidation yolwelo lwesilivere, kwaye ulawulo oluchanekileyo lweqondo lokushisa luqinisekisa ukuba ulwelo lwesilivere luhamba ngokufanelekileyo, luzalise ngokulinganayo zonke iinkcukacha zokubumba. Imveliso yokugqibela inemizila egudileyo kunye neepatheni ezicacileyo, eziphantse zifane noyilo loyilo.

Nangona kunjalo, kukwakho iimeko zemingeni kunye neentsilelo. Umdali uzame ukwenza isacholo segolide enamaleko amaninzi anamalungu ajikelezayo. Nangona usebenzisa ii-molds ezichanekileyo, imveliso yokugqibela ibonise ukuguqulwa okuncinci ngenxa yezinga eliphezulu lokunciphisa igolide kunye neenguqu ezixinzelelekileyo zoxinzelelo lwesakhiwo se-multi-layered ngexesha lokupholisa. Ukulungelelaniswa kwamacandelo ajikelezayo kwakungachanekanga ngokwaneleyo, okuchaphazela umphumo jikelele. Oku kubonisa ukuba oomatshini abancinci bokuphosa ubucwebe basafuna ukuqhubeka nokuphonononga ukuphuculwa kwenkqubo kunye nokuphuculwa kwetekhnoloji xa bejongene nezitayile ezintsonkothileyo ezifuna ukuchaneka kolwakhiwo oluphezulu.

Oomatshini abancinci bokuphosa ubucwebe banobuchule obuthile ekudaleni ngokuchanekileyo izitayela ezinzima, kwaye ukusebenza kwabo kuyaqhubeka nokuphucula kunye nokuqhubela phambili kwezobuchwepheshe. Ngokubumba okukumgangatho ophezulu, izixhobo ezihambelanayo, kunye nolawulo oluchanekileyo lweparamitha yenkqubo, kunokwenzeka ukufezekisa ukuphoswa komgangatho ophezulu woyilo oluninzi olunzima. Nangona kunjalo, ayinakuphikiswa ukuba kusekho imida xa kujongwa izitayile ezifuna izakhiwo ezintsonkothileyo kunye nokuchaneka okuphezulu.

Kwixesha elizayo, ngophuhliso olulungelelanisiweyo lwenzululwazi yemathiriyeli, itekhnoloji yokwenziwa komngundo, kunye neenkqubo zokuphosa, oomatshini abancinci bokuphosa izacholo kulindeleke ukuba bafezekise impumelelo enkulu kwinkalo yokudala isitayile esintsonkothileyo, ukuzisa amathuba angakumbi okudala ubucwebe kunye nokunceda ishishini lifikelele kwiindawo eziphakamileyo.

Ungaqhagamshelana nathi ngezi ndlela zilandelayo:

Whatsapp: 008617898439424

I-imeyile:sales@hasungmachinery.com

IWebhu: www.hasungmachinery.com www.hasungcasting.com

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjineli boomatshini ekwimazantsi eTshayina, kwisixeko esihle nesikhula ngokukhawuleza kwezoqoqosho, iShenzhen. Le nkampani yinkokheli kwezobuchwepheshe kwicandelo lezixhobo zokufudumeza nokuthunga izixhobo zesinyithi esixabisekileyo kunye neshishini lezinto ezintsha.

Ulwazi lwethu olomeleleyo kubuchwepheshe bokuphosa i-vacuum lusenza sikwazi ukunceda abathengi bemizi-mveliso ukuphosa intsimbi exutywe kakhulu, i-platinum-rhodium alloy efunekayo kakhulu, igolide nesilivere, njl.

Umnxeba: +86 17898439424

I-imeyile:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Idilesi: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115