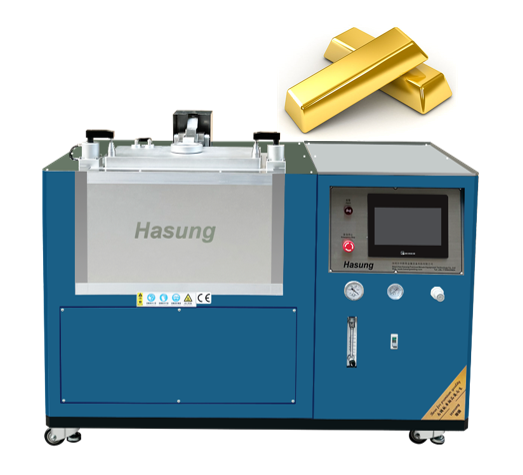

Ingaba umatshini wokugalela webha yegolide ozenzekela ngokuzeleyo unokugqobhoza njani umqobo wokusabisa wemveli?

Kwishishini elixabisekileyo lokusulungekisa isinyithi, indlela yokuphosa yemveli ayisebenzi kwaye ibe ngumqobo othintela ubungakanani bemveliso kunye nokusebenza kakuhle. Ukuvela koomatshini bokwenza ibha yegolide ngokuzenzekela ngokugqibeleleyo kuzoyise ngempumelelo ezi ntsilelo ngokusebenzisa iindlela ezahlukeneyo zobugcisa kunye nokuphucula, ukuzuza uphuculo olubalulekileyo ekusebenzeni kakuhle kunye nomgangatho.

1.Inkqubo yokuvelisa ngokuzenzekelayo

(1) Kwinkqubo yokuphosa ingot yendabuko, inani elikhulu lomsebenzi wezandla lihlala lifunwa ukusuka ekulungiseleleni izinto eziluhlaza, ukunyibilika, ukuphosa kwi-processing elandelayo, engeyiyo kuphela engasebenziyo kodwa ejongene neempazamo zabantu. Umatshini wokugalela ibha yegolide ngokuzenzekela ngokupheleleyo ufezekise inkqubo epheleleyo yokuzenzekela. Ixhotyiswe ngendlela yokutya ephucukileyo enokubeka ngokuzenzekelayo imathiriyeli yentsimbi exabisekileyo enobunzima obumiselweyo kwiikhatriji ze-inki zamatye okanye ezinye iimolds.

(2) Indlela yokuhambisa iyakuthutha ngokuchanekileyo ukungunda okunemathiriyeli ekrwada ukuya kwigumbi le-vacuum yokunyibilikisa ikristale, apho imathiriyeli ekrwada inyibilikiswa ngokuzenzekelayo, ipholiswe kwaye ikhazimliswe ukwenza imivalo yegolide. Imivalo yegolide eyenziweyo ithuthwa isiwe kwimodyuli yasemva kokulungiswa ngokusebenzisa indlela yokusika ukuze ihlolwe, ukumakisha, isitampu, ukulinganisa, kunye nemisebenzi yokupakisha. Yonke le nkqubo ayifuni ukungenelela ngesandla, ukunciphisa iindleko zabasebenzi kunye nokulibaziseka kwemveliso okubangelwa yimiba yabantu, ukuphucula kakhulu ukusebenza kwemveliso.

2.Inkqubo yokufudumala esebenzayo kunye nokupholisa

(1) Itekhnoloji yokufudumeza ngokukhawuleza: Oomatshini bokugalela ingot yegolide ezenzekelayo ngokuqhelekileyo basebenzisa itekhnoloji yokufudumeza ephezulu. Xa kuthelekiswa neendlela zokufudumeza amadangatye esintu okanye iindlela zokufudumeza ukuxhathisa, ukufudumeza kwe-induction kunokufudumeza ngokukhawuleza nangokulinganayo imathiriyeli yesinyithi exabisekileyo kwiqondo lobushushu elifunekayo lokunyibilika.

Ngokomzekelo, abanye oomatshini bokuphosa i-ingot baxhotyiswe ngeejenereyitha zokungenisa amandla aphezulu, ezinokutshisa izinto eziluhlaza ngaphezu kwendawo yokunyibilika ngexesha elifutshane, ukunciphisa kakhulu ixesha lokunyibilika. Ngaphezu koko, ukufudumeza kwe-induction kuqhutyelwa kwindawo ye-vacuum, ukuphepha i-oxidation ebangelwa ukudibanisa phakathi kwesinyithi kunye nomoya, kunye nokuphucula ukucoceka kunye nomgangatho weebha zegolide.

(2) Inkqubo yokupholisa elungiselelwe: Isantya sokupholisa sikwabalulekile ekusebenzeni kakuhle kwe-ingot kunye nomgangatho. Indlela yokupholisa yoomatshini bokuphosa be-ingot bemveli isoloko inokusebenza okuphantsi, okukhokelela kwimijikelo emide yokuphosa ingot. Umatshini wokugalela ingot wegolide ozenzekela ngokugqibeleleyo wamkela ukupholisa kwamanzi okufanelekileyo okanye inkqubo yokupholisa umoya, kwaye ezinye zidibanisa negumbi lokucoca elipholileyo lamanzi kunye nomzila wokuhambisa amanzi opholileyo.

Ezi nkqubo zokupholisa zinokususa ngokukhawuleza ubushushu, zivumela isinyithi esityhidiweyo ukuba sipholile kwaye sikhanye ngexesha elifutshane. Oku akuphuculi nje ukusebenza kakuhle kwemveliso kodwa kwandisa ubume bangaphakathi kunye neempawu zemivalo yegolide, ukunciphisa ukwenzeka kweziphene. Ngokomzekelo, ngokulawula ngokuchanekileyo izinga lokuhamba kunye nokushisa kwamanzi okupholisa, inkqubo ye-crystallization ye-bars yegolide inokwenziwa ifanayo ngakumbi, ukuphucula ukuhambelana kwemveliso.

I-3.Inkqubo yokulawula echanekileyo ephezulu

(1) Ulawulo lobushushu: Inkqubo yolawulo yomatshini wokugalela ibha yegolide ngokuzenzekelayo inokulawula ngokuchanekileyo ubushushu ngexesha lokufudumeza kunye neenkqubo zokupholisa. Ngokufakela iqondo lokushisa kwiindawo ezibalulekileyo, utshintsho lwexesha langempela lujongwa kwaye idatha ibuyiselwa kwinkqubo yokulawula.

Inkqubo yokulawula ngokuzenzekelayo ilungelelanisa amandla okufudumeza okanye isantya sokupholisa ngokusekelwe kwiiparamitha zokushisa kwangaphambili ukuze kuqinisekiswe ukuba yonke inkqubo yokuphosa iqhutywe ngaphakathi kwinqanaba elichanekileyo lokushisa. Oku akuncedi nje kuphela ukuphucula umgangatho kunye nokuzinza kweengots, kodwa kwakhona kuthintela iingozi zemveliso okanye i-scrap yemveliso ebangelwa ukuguquguquka kweqondo lokushisa.

(2) Ulawulo lobunzima: Kwii-ingots zentsimbi ezixabisekileyo, ukuchaneka okuphezulu kakhulu kuyafuneka kubunzima beebha zegolide. Umatshini wokuphosa we-ingot ngokuzenzekelayo unokulawula ngokuchanekileyo inani legalelo lezinto eziluhlaza kunye nobunzima bemivalo yegolide egqityiweyo ngokusebenzisa ubungakanani obuphambili kunye neenkqubo zokulawula.

Ngexesha lenkqubo yokutya, isixhobo sokulinganisa siya ngokuchanekileyo ukulinganisa ubunzima bezinto eziluhlaza ukuqinisekisa ukuba ubunzima begalelo ngalinye lezinto eziluhlaza zidibana nexabiso elimiselweyo. Emva kokuba uphononongo lugqityiwe, isixhobo sokulinganisa siya kuphinda silinganise imivalo yegolide. Kwimivalo yegolide enobunzima obungahambelaniyo nomgangatho, inkqubo iya kuzicwangcisa ngokuzenzekelayo, njengokunyibilikisa okanye ukulungisa ubunzima, ukuqinisekisa ukuba ubunzima bebha yegolide nganye bungaphakathi koluhlu lwempazamo oluchaziweyo.

4.Ukuphuculwa kokungunda kunye neteknoloji yokuhambisa

(1) Iimathiriyeli zokubumba ezikumgangatho ophezulu kunye noyilo: Umatshini wokuphosa webha yegolide ozenzekela ngokugqibeleleyo wamkela izinto zokubumba ezisebenza kakhulu, ezinokumelana nobushushu obuphezulu, ukumelana nokunxiba, kunye nokuhanjiswa kwe-thermal. Ngokomzekelo, ezinye iimolds zisebenzisa i-graphite ekhethekileyo okanye izinto ze-alloy ezinokumelana nokukhukuliseka kwesinyithi esinyibilikisiweyo esiphezulu sobushushu kunye nokugcina ukuchaneka kwe-dimensional kunye nomgangatho ophezulu ngexesha lokusetyenziswa ngokuphindaphindiweyo.

Kwangaxeshanye, uyilo lokungunda luphuculwe ukuba lube nethambeka elibunjwayo elifanelekileyo kunye noburhabaxa bomphezulu, obuququzelela ukudilizwa okugudileyo kwemivalo yegolide emva kokupholisa, ukunciphisa ukuphazamiseka kwemveliso kunye nomonakalo wokungunda obangelwa kukudilizwa nzima.

(2) Isixhobo sokuhambisa ngokufanelekileyo: Indlela yokuhambisa yenye yezinto eziphambili zokuqinisekisa ukusebenza okuqhubekayo kunye nokusebenza kakuhle komatshini wokuphosa ingot. Isixhobo sokuhambisa somatshini wokujula we-ingot webhanti wegolide sisebenzisa ikhonkco eliphambili okanye itekhnoloji yokuhambisa ibhanti, eneempawu zokuchaneka okuphezulu, isantya esiphezulu kunye nokuthembeka okuphezulu.

Isixhobo sokuhambisa sinokuhambisa ngokuchanekileyo ukubumba phakathi kweendawo zokusebenza ezahlukeneyo kunye nokugcina uzinzo ngexesha lenkqubo yokuhambisa, ukuphepha ukugungqa okanye ukungqubana kwesikhunta kunye nokuqinisekisa ukubunjwa komgangatho wemivalo yegolide. Ukongeza, abanye oomatshini bokuphosa i-ingot baxhotyiswe ngokufumanisa ngokuzenzekelayo kunye nezixhobo zohlengahlengiso, ezinokubeka iliso kwimeko yokusebenza kwesixhobo sokuhambisa ngexesha langempela, ukufumanisa nokusombulula iingxaki ezinokwenzeka ngexesha elifanelekileyo, kunye nokuqinisekisa ukuqhubeka kwemveliso.

5.Ukubona kwi-intanethi kunye nokulawula umgangatho

Umatshini wokuphosa we-ingot wegolide ozenzekelayo ozenzekelayo udibanisa inkqubo yokukhangela kwi-intanethi, enokwenza ukukhangela kwexesha langempela lokubonakala, ubungakanani, ubunzima, njl njl. Imivalo yegolide ngexesha lenkqubo yokuvelisa. Ngokomzekelo, ngokusebenzisa inkqubo yokuhlola okubonakalayo, kunokwenzeka ukufumanisa ukuba kukho iziphene, imikrwelo, okanye amaqamza kumphezulu webhari yegolide; Ngenkqubo yokulinganisa i-laser, ukuchaneka kobukhulu beentsimbi zegolide kunokulinganiswa ngokuchanekileyo.

Emva kokuba iimveliso ezingahambelaniyo zifunyenwe, inkqubo iya kuzisusa ngokuzenzekelayo kwaye irekhode idatha efanelekileyo yokuhlalutya kunye nokuphuculwa kwenkqubo yokuvelisa. Lo mgangatho wokulawula umgangatho wangempela unceda ukufumanisa iingxaki kwimveliso ngexesha elifanelekileyo, ukuphepha ukuveliswa kwenani elikhulu leemveliso ezingafanelekanga, kunye nokuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso.

Isishwankathelo, umatshini wokuphosa we-ingot wegolide ozenzekelayo uye waqhekeza ngempumelelo ibhotile ye-ingot yendabuko ngokusebenzisa izinto ezintsha ezahlukeneyo kunye nokulungiswa okufana neenkqubo zokuvelisa ngokuzenzekelayo, ukufudumeza okusebenzayo kunye neenkqubo zokupholisa, iinkqubo zokulawula ezichanekileyo, ukuphuculwa kokubumba kunye nokuhambisa iteknoloji, kunye nokufunyanwa kwe-intanethi kunye nokulawula umgangatho. Iphumelele ukusebenza kakuhle, umgangatho ophezulu, kunye ne-automation ekuveliseni i-ingots zetsimbi ezixabisekileyo, ukubonelela ngenkxaso eqinile yobugcisa kuphuhliso lwamashishini afana nokusulungekiswa kwegolide.

Ungaqhagamshelana nathi ngezi ndlela zilandelayo:

Whatsapp: 008617898439424

I-imeyile:sales@hasungmachinery.com

IWebhu: www.hasungmachinery.com www.hasungcasting.com

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjineli boomatshini ekwimazantsi eTshayina, kwisixeko esihle nesikhula ngokukhawuleza kwezoqoqosho, iShenzhen. Le nkampani yinkokheli kwezobuchwepheshe kwicandelo lezixhobo zokufudumeza nokuthunga izixhobo zesinyithi esixabisekileyo kunye neshishini lezinto ezintsha.

Ulwazi lwethu olomeleleyo kubuchwepheshe bokuphosa i-vacuum lusenza sikwazi ukunceda abathengi bemizi-mveliso ukuphosa intsimbi exutywe kakhulu, i-platinum-rhodium alloy efunekayo kakhulu, igolide nesilivere, njl.

Umnxeba: +86 17898439424

I-imeyile:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Idilesi: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115