Yuav ua li cas lub tag nrho tsis siv neeg kub bar casting tshuab tawg los ntawm lub efficiency bottleneck ntawm tsoos casting?

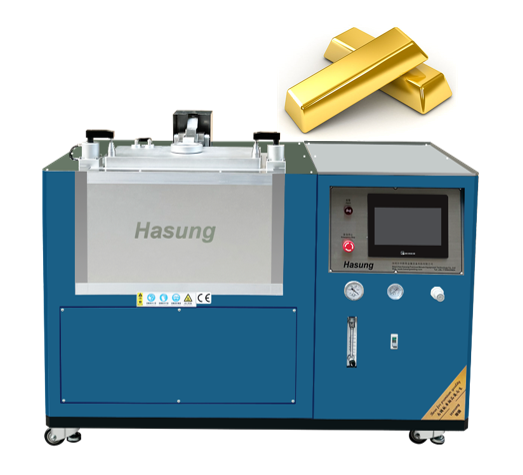

Hauv kev lag luam muaj txiaj ntsig zoo ntawm cov hlau ua kom zoo, cov txheej txheem casting ib txwm tsis muaj txiaj ntsig thiab tau dhau los ua ib qho kev txwv tsis pub ntau lawm thiab kev ua haujlwm. Qhov tshwm sim ntawm tag nrho tsis siv neeg kub bar casting tshuab tau ntse kov yeej cov bottlenecks los ntawm ntau yam technological innovations thiab optimizations, ua kom tiav cov kev txhim kho tseem ceeb hauv casting efficiency thiab zoo.

1. Automated ntau lawm txheej txheem

(1) Nyob rau hauv cov txheej txheem ingot casting txheej txheem, ib tug loj npaum li cas ntawm phau ntawv ua hauj lwm yog feem ntau yuav tsum tau los ntawm raw khoom npaj, melting, casting mus rau tom ntej ua, uas tsis yog tsuas yog inefficient tab sis kuj ua rau tib neeg yuam kev. Lub siab tsis siv neeg kub bar casting tshuab tau tiav tag nrho cov txheej txheem automation. Nws yog txawm peem rau nrog ib tug advanced feeding mechanism uas yuav cia li tso precious hlau raw cov ntaub ntawv ntawm ib tug teem luj rau hauv pob zeb number case cartridges los yog lwm yam pwm.

(2) Lub tshuab conveying yuav raug thauj cov pwm uas muaj cov ntaub ntawv raw mus rau lub tshuab nqus tsev melting crystallization chamber, qhov twg cov ntaub ntawv raw tau cia li melted, txias thiab crystallized los ua kub tuav. Cov khoom kub tsim tau raug thauj mus rau tom qab kev ua haujlwm los ntawm kev txiav cov txheej txheem rau kev tshuaj xyuas, kos npe, stamping, hnyav, thiab kev ua haujlwm stacking. Tag nrho cov txheej txheem tsis tas yuav muaj kev cuam tshuam los ntawm phau ntawv, txo cov nqi zog thiab kev ua haujlwm qeeb vim yog tib neeg, kev txhim kho ntau lawm.

2.Efficient cua sov thiab txias system

(1) Cov tshuab cua kub ceev: Tsis siv neeg kub ingot casting tshuab feem ntau siv cov tshuab cua sov siab heev. Piv rau cov nplaim hluav taws kub cua sov los yog cov cua kub tsis kam, induction cua sov tuaj yeem ua kom sov thiab sib npaug ntawm cov khoom siv hlau zoo nkauj rau qhov xav tau melting kub.

Piv txwv li, qee lub tshuab ingot casting yog nruab nrog lub tshuab hluav taws xob siab induction, uas tuaj yeem ua kom sov cov ntaub ntawv raw saum lub melting point nyob rau lub sij hawm luv luv, zoo heev txo lub sij hawm melting. Ntxiv mus, induction cua sov yog ua nyob rau hauv ib qho chaw nqus tsev vacuum, tsis txhob oxidation tshwm sim los ntawm kev sib cuag ntawm hlau thiab huab cua, thiab txhim kho lub purity thiab zoo ntawm kub tuav.

(2) Kev ua kom txias txias: txias ceev kuj tseem ceeb heev rau ingot efficiency thiab zoo. Cov txheej txheem txias ntawm cov tsoos ingot casting tshuab feem ntau muaj kev ua haujlwm tsawg, ua rau ntev ingot casting cycles. Lub tshuab ua haujlwm kub tsis siv neeg lub tshuab ua kom zoo siv lub tshuab ua kom txias lossis cua txias, thiab qee qhov kuj muab cov dej txias hauv lub tshuab nqus tsev thiab cov dej txias conveyor.

Cov tshuab cua txias no tuaj yeem tshem tawm cov cua sov sai sai, cia cov hlau molten txias thiab crystallize nyob rau lub sijhawm luv luv. Qhov no tsis tsuas yog txhim kho kev tsim khoom, tab sis kuj txhim kho cov qauv sab hauv thiab cov khoom ntawm cov khoom kub, txo qhov tshwm sim ntawm qhov tsis xws luag. Piv txwv li, los ntawm kev tswj hwm tus nqi ntws thiab qhov kub thiab txias ntawm cov dej txias, cov txheej txheem crystallization ntawm cov khoom kub tuaj yeem ua kom zoo dua qub, txhim kho cov khoom sib xws.

3.High precision tswj qhov system

(1) Kev tswj qhov kub thiab txias: Cov kev tswj hwm ntawm lub tshuab kub kub tsis siv neeg tuaj yeem tswj tau qhov kub thiab txias thaum lub sijhawm cua sov thiab cua txias. Los ntawm kev txhim kho qhov ntsuas kub ntawm qhov chaw tseem ceeb, lub sijhawm hloov pauv kub ntawm lub sijhawm raug saib xyuas thiab cov ntaub ntawv raug xa rov qab mus rau qhov system tswj.

Lub kaw lus tswj tau hloov kho lub zog cua sov lossis cua txias ceev raws li qhov ntsuas kub ntawm qhov ntsuas kub ua ntej kom ntseeg tau tias tag nrho cov txheej txheem casting yog ua tiav nyob rau hauv qhov kub thiab txias. Qhov no tsis tsuas yog pab txhim kho qhov zoo thiab ruaj khov ntawm ingots, tab sis kuj zam kev tsim khoom raug mob lossis cov khoom seem los ntawm qhov kub thiab txias.

(2) Kev tswj qhov hnyav: Hauv cov khoom siv hlau muaj nuj nqis, qhov siab tshaj plaws yog qhov yuav tsum tau muaj rau qhov hnyav ntawm cov khoom kub. Lub tshuab tsis siv neeg puv ingot casting tuaj yeem tswj xyuas cov khoom nkag ntawm cov ntaub ntawv raw thiab qhov hnyav ntawm cov khoom kub tiav los ntawm kev hnyav hnyav thiab tswj cov tshuab.

Thaum lub sij hawm pub mis, cov khoom hnyav yuav ntsuas qhov hnyav ntawm cov khoom siv raw kom paub tseeb tias qhov hnyav ntawm txhua qhov kev tawm tswv yim ntawm cov khoom siv raw khoom ua tau raws li tus nqi teev. Tom qab qhov kev ua tiav tiav, cov cuab yeej ntsuas yuav rov ntsuas cov khoom kub. Rau cov khoom kub uas nws qhov hnyav tsis tau raws li tus qauv, lub kaw lus yuav cia li ua rau lawv, xws li remelting lossis kho qhov hnyav, kom ntseeg tau tias qhov hnyav ntawm txhua qhov kub yog nyob rau hauv qhov kev ua yuam kev.

4.Kev txhim kho pwm thiab kev siv tshuab

(1) Cov ntaub ntawv pwm zoo thiab tsim qauv: Lub tshuab ua haujlwm kub tsis zoo no feem ntau siv cov khoom pwm ua haujlwm siab, uas muaj qhov kub thiab txias tsis kam, hnav tsis kam, thiab thermal conductivity. Piv txwv li, qee cov pwm siv cov khoom siv tshwj xeeb graphite lossis hlau alloy uas tuaj yeem tiv taus qhov yaig ntawm cov hlau kub kub thiab tswj qhov raug qhov tseeb thiab qhov zoo ntawm qhov chaw thaum rov siv dua.

Nyob rau tib lub sijhawm, tus qauv tsim pwm tau ua kom zoo dua kom muaj qhov tsim nyog demolding txoj kab nqes thiab qhov chaw roughness, uas ua kom yooj yim demolding ntawm cov kub tuav tom qab txias, txo cov kev cuam tshuam ntau lawm thiab pwm puas los ntawm kev nyuaj demolding.

(2) Cov cuab yeej siv tau zoo: Lub tshuab xa khoom yog ib qho ntawm cov khoom tseem ceeb los xyuas kom meej kev ua haujlwm tsis tu ncua thiab ua haujlwm zoo ntawm lub tshuab ingot casting. Lub tshuab conveying ntawm lub siab tsis siv neeg kub bar ingot casting tshuab txais cov saw zoo tshaj plaws los yog siv cov cuab yeej siv, uas muaj cov yam ntxwv ntawm kev ua haujlwm siab, kev kub ceev, thiab kev ntseeg siab.

Cov khoom siv conveying tuaj yeem thauj cov pwm ntawm ntau qhov chaw ua haujlwm thiab tswj kev ruaj ntseg thaum lub sijhawm thauj khoom, tsis txhob cuam tshuam los yog sib tsoo ntawm cov pwm thiab ua kom cov khoom zoo ntawm cov khoom kub. Tsis tas li ntawd, qee lub tshuab ingot casting yog nruab nrog cov cuab yeej tsis siv neeg tshawb pom thiab hloov kho, uas tuaj yeem saib xyuas cov xwm txheej ntawm cov khoom siv thauj khoom hauv lub sijhawm, tshawb xyuas thiab daws cov teeb meem tshwm sim raws sijhawm, thiab xyuas kom muaj kev tsim khoom txuas ntxiv.

5.Online nrhiav thiab tswj kom zoo

Lub tag nrho tsis siv neeg kub bar ingot casting tshuab integrates ib tug online nrhiav kom tau system, uas yuav ua tau tiag-lub sij hawm nrhiav kom tau cov tsos, loj, hnyav, thiab lwm yam ntawm cov kub tuav thaum lub sij hawm ntau lawm txheej txheem. Piv txwv li, los ntawm kev tshuaj xyuas qhov muag pom, nws tuaj yeem tshawb xyuas seb puas muaj qhov tsis xws luag, khawb, lossis npuas ntawm qhov chaw kub; Los ntawm lub tshuab ntsuas laser, qhov tseeb qhov tseeb ntawm cov khoom kub tuaj yeem ntsuas qhov tseeb.

Thaum pom cov khoom tsis sib haum, lub kaw lus yuav tshem tawm lawv thiab sau cov ntaub ntawv cuam tshuam rau kev txheeb xyuas thiab txhim kho cov txheej txheem tsim khoom. Qhov kev ntsuas kev tswj xyuas zoo hauv lub sijhawm no pab txhawm rau txheeb xyuas cov teeb meem hauv kev tsim khoom raws sijhawm, zam kev tsim khoom ntawm ntau cov khoom tsis tsim nyog, thiab txhim kho kev tsim khoom thiab cov khoom zoo.

Nyob rau hauv cov ntsiab lus, lub siab tsis siv neeg kub ingot casting tshuab tau ntse tawg los ntawm lub bottleneck ntawm ib txwm ingot efficiency los ntawm ntau yam nrhav thiab optimizations xws li automated ntau lawm txheej txheem, npaum cua sov thiab txias tshuab, high-precision tswj systems, txhim kho pwm thiab conveying technology, thiab online nrhiav kom tau thiab zoo tswj. Nws tau ua tiav high efficiency, zoo, thiab automation nyob rau hauv zus tau tej cov precious hlau ingots, muab muaj zog technical support rau txoj kev loj hlob ntawm industries xws li kub refining.

Koj tuaj yeem tiv tauj peb los ntawm txoj kev hauv qab no:

Whatsapp: 008617898439424

Email:sales@hasungmachinery.com

Lub Vev Xaib: www.hasungmachinery.com www.hasungcasting.com

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115