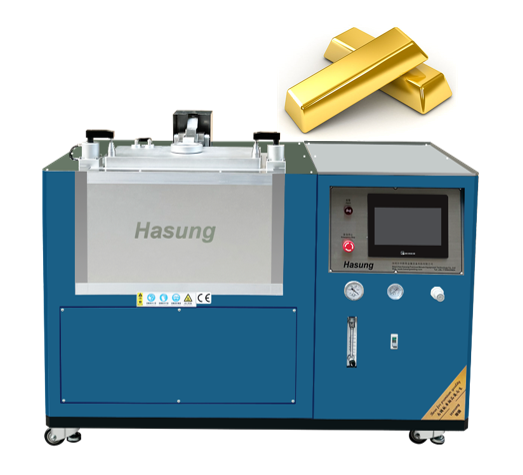

UHasung ungumkhiqizi womshini wokubumba nokuncibilikisa izinsimbi eziyigugu ochwepheshe kusukela ngo-2014.

Umshini wokulingisa ibha yegolide ozenzakalelayo ngokuphelele ungagqashula kanjani ibhodlela elisebenza kahle lokulingisa okuvamile?

Embonini yokucwenga insimbi eyigugu, indlela yokulingisa evamile ayisebenzi kahle futhi isiphenduke umgoqo ovimbela isikali sokukhiqiza nokusebenza kahle. Ukuvela kwemishini yokuphonsa ibha yegolide ezenzakalelayo ngokuphelele kunqobe ngempumelelo lezi zingqinamba ngokusebenzisa izinto ezintsha zobuchwepheshe ezihlukahlukene nokuthuthukisa, kuzuze intuthuko ebalulekile ekusebenzeni kahle kokusakaza kanye nekhwalithi.

1.Inqubo yokukhiqiza ezenzakalelayo

(1) Enqubweni yokusakazwa kwe-ingot yendabuko, inani elikhulu lokusebenza okwenziwa ngesandla livame ukudingeka kusukela ekulungiseni impahla eluhlaza, ukuncibilika, ukuphonsa ekucubunguleni okulandelayo, okungeyona nje into engasebenzi kahle kodwa futhi ejwayele ukuba namaphutha abantu. Umshini wokukhipha ibha yegolide ozenzakalelayo ngokugcwele uzuze inqubo ezenzakalelayo yokuzenzakalela. Ifakwe indlela yokudla ethuthukisiwe engabeka ngokuzenzakalelayo izinto zokusetshenziswa zensimbi eziyigugu zesisindo esimisiwe kumakhatriji kayinki wamatshe noma ezinye isikhunta.

(2) Indlela yokudlulisa izothutha ngokunembile isikhunta esiqukethe izinto zokusetshenziswa siye egumbini le-vacuum melting crystallization, lapho izinto zokusetshenziswa zincibilika ngokuzenzakalelayo, zipholiswe futhi zifakwe ikristalu ukuze zenze izigxobo zegolide. Izigxobo zegolide ezakhiwe zithuthelwa kumojula yangemva kokucubungula ngokusebenzisa indlela yokusika ukuze ihlolwe, imakwe, igxivizwe, ikale, kanye nemisebenzi yokupakisha. Yonke le nqubo ayidingi ukungenelela okwenziwa ngesandla, ukunciphisa izindleko zabasebenzi kanye nokubambezeleka kokukhiqiza okubangelwa izici zabantu, kuthuthukisa kakhulu ukusebenza kahle kokukhiqiza.

2.Isistimu yokushisa esebenzayo kanye nokupholisa

(1) Ubuchwepheshe bokushisa obusheshayo: Imishini yokukhipha ingot yegolide ezenzakalelayo ngokugcwele ivamise ukusebenzisa ubuchwepheshe bokushisisa obusezingeni eliphezulu. Uma kuqhathaniswa nezindlela zokushisisa ilangabi elivamile noma izindlela zokushisisa ukumelana, ukufudumeza kwe-induction kungashisisa ngokushesha nangokulinganayo izinto zokusetshenziswa zensimbi eziyigugu kuzinga lokushisa elincibilikayo elifunekayo.

Isibonelo, eminye imishini yokukhipha i-ingot ifakwe amajeneretha angenisa amandla aphezulu, angashisisa izinto zokusetshenziswa ngaphezu kwendawo encibilikayo ngesikhathi esifushane, okunciphise kakhulu isikhathi sokuncibilika. Ngaphezu kwalokho, ukushisa kwe-induction kwenziwa endaweni ye-vacuum, ukugwema i-oxidation ebangelwa ukuxhumana phakathi kwensimbi nomoya, kanye nokwenza ngcono ukuhlanzeka kanye nekhwalithi yemigoqo yegolide.

(2) Isistimu yokupholisa elungiselelwe: Isivinini sokupholisa sibalulekile ekusebenzeni kahle kwe-ingot kanye nekhwalithi. Indlela yokupholisa yemishini yokukhipha ingot yendabuko ivamise ukuba nokusebenza kahle okuphansi, okuholela emijikelezweni emide yokuphonsa ingot. Umshini wokuphonsa we-ingot wegolide ozenzakalelayo ngokuphelele wamukela isistimu yokupholisa amanzi esebenza kahle noma isistimu yokupholisa umoya, futhi enye ihlanganisa negumbi levacuum elipholiswe ngamanzi kanye nethrekhi yokuthutha epholiswe ngamanzi.

Lezi zinhlelo zokupholisa zingasusa ngokushesha ukushisa, zivumele insimbi encibilikisiwe ukuthi iphole futhi icwebezele ngesikhathi esifushane. Lokhu akugcini nje ngokuthuthukisa ukusebenza kahle kokukhiqiza kodwa futhi kuthuthukisa ukwakheka kwangaphakathi kanye nezakhiwo zemigoqo yegolide, kunciphisa ukwenzeka kokukhubazeka. Isibonelo, ngokulawula ngokunembile izinga lokugeleza kanye nezinga lokushisa lamanzi okupholisa, inqubo ye-crystallization yamabha egolide ingenziwa iyunifomu eyengeziwe, ukuthuthukisa ukungaguquguquki komkhiqizo.

I-3.Isistimu yokulawula ukunemba okuphezulu

(1) Ukulawula izinga lokushisa: Isistimu yokulawula yomshini wokuphonsa ibha yegolide ezenzakalelayo ngokugcwele ingalawula ngokunembile izinga lokushisa ngesikhathi sezinqubo zokushisisa nokupholisa. Ngokufaka izinzwa zokushisa ezindaweni ezibucayi, izinguquko zezinga lokushisa lesikhathi sangempela ziyagadwa futhi idatha ibuyiselwa ohlelweni lokulawula.

Isistimu yokulawula ilungisa ngokuzenzakalelayo amandla okushisa noma isivinini sokupholisa ngokusekelwe kumingcele yezinga lokushisa elisethiwe ukuze kuqinisekiswe ukuthi yonke inqubo yokusakaza yenziwa ngaphakathi kwebanga lokushisa elinembile. Lokhu akusizi nje ukuthuthukisa ikhwalithi nokuzinza kwama-ingot, kodwa futhi kugwema izingozi zokukhiqiza noma izinsalela zomkhiqizo ezibangelwa ukushintshashintsha kwezinga lokushisa.

(2) Ukulawula isisindo: Kuma-ingo ensimbi ayigugu, ukunemba okuphezulu kakhulu kuyadingeka esisindweni samabha egolide. Umshini wokuphonsa we-ingot ozenzakalelayo ngokuphelele ungalawula ngokunembile inani lokufakwayo lezinto ezingavuthiwe kanye nesisindo semigoqo yegolide eqediwe ngokusebenzisa izinhlelo ezithuthukisiwe zokukala nokulawula.

Phakathi nenqubo yokondla, idivayisi yokukala izokala ngokunembile isisindo sezinto ezingavuthiwe ukuze kuqinisekiswe ukuthi isisindo sokufakwa ngakunye kwezinto zokusetshenziswa sihlangabezana nenani elimisiwe. Ngemva kokuphothulwa kokulingisa, idivayisi yokukala izokala kabusha amabha egolide. Kumabha egolide isisindo sawo esingahlangabezani nendinganiso, isistimu izowacubungula ngokuzenzakalelayo, njengokuncibilika kabusha noma ukulungisa isisindo, ukuze kuqinisekiswe ukuthi isisindo sebha yegolide ngayinye singaphakathi kwebanga lephutha elishiwo.

4.Ukuthuthukiswa kwesikhunta kanye nobuchwepheshe bokudlulisa

(1) Izinto zokubumba zekhwalithi ephezulu kanye nomklamo: Umshini wokuphonsa webha yegolide ozenzakalelayo ngokugcwele wamukela izinto zokubunjwa ezisebenza kahle, ezinokumelana okuhle kwezinga lokushisa eliphezulu, ukumelana nokugqokwa, kanye ne-thermal conductivity. Isibonelo, ezinye isikhunta zisebenzisa izinto ezikhethekile ze-graphite noma i-alloy ezingamelana nokuguguleka kwensimbi encibilikisiwe yezinga lokushisa eliphezulu futhi zigcine ukunemba kobukhulu kanye nekhwalithi yobuso phakathi nokusetshenziswa okuphindaphindiwe.

Ngaso leso sikhathi, idizayini yesikhunta seyenziwe yathuthukiswa ukuze ibe nendawo eyehlelayo efanelekile kanye nokubangwadlana kwendawo, okusiza ukubhidlizwa kahle kwezigxobo zegolide ngemva kokupholisa, ukunciphisa ukuphazamiseka kokukhiqiza kanye nokulimala kwesikhunta okubangelwa ukubhidlizwa okunzima.

(2) Idivayisi yokudlulisa ephumelelayo: Indlela yokudlulisa ingenye yezingxenye ezibalulekile zokuqinisekisa ukusebenza okuqhubekayo nokusebenza kahle komshini wokukhipha ingot. Idivayisi yokudlulisa yomshini wokulingisa we-ingot yebha yegolide ezenzakalelayo isebenzisa ubuchwepheshe obuthuthukisiwe bokudluliswa kweketango noma ibhande, obunezici zokunemba okuphezulu, isivinini esikhulu, nokuthembeka okuphezulu.

Ithuluzi elidlulisayo lingakwazi ukuthutha ngokunembile isikhunta phakathi kwezindawo zokusebenza ezihlukahlukene futhi ligcine ukuzinza phakathi nenqubo yokudlulisa, ligweme ukuthuthumela noma ukungqubuzana kwesikhunta kanye nokuqinisekisa ikhwalithi yokwakheka kwezigxobo zegolide. Ngaphezu kwalokho, eminye imishini yokukhipha i-ingot ifakwe amadivayisi okubona ngokuzenzakalela kanye nokulungisa, angakwazi ukuqapha isimo sokusebenza kwedivayisi yokudlulisa ngesikhathi sangempela, ibone futhi ixazulule izinkinga ezingenzeka ngesikhathi esifanele, futhi iqinisekise ukuqhubeka kokukhiqiza.

5.Ukutholwa ku-inthanethi nokulawula ikhwalithi

Umshini wokusakaza we-ingot yebha yegolide ozenzakalelayo ngokugcwele uhlanganisa isistimu yokuthola ku-inthanethi, engakwazi ukubona ngesikhathi sangempela ukubukeka, usayizi, isisindo, njll. samabha egolide phakathi nenqubo yokukhiqiza. Isibonelo, ngesistimu yokuhlola okubukwayo, kuyenzeka ukuthi kutholwe ukuthi kukhona yini ukukhubazeka, ukuklwebheka, noma amabhamuza ebusweni bebha yegolide; Ngesistimu yokulinganisa i-laser, ukunemba kwe-dimensional kwamabha egolide kungalinganiswa ngokunembile.

Uma imikhiqizo engavumelani isitholiwe, isistimu izoyisusa ngokuzenzakalelayo futhi irekhode idatha efanele ukuze ihlaziywe futhi ithuthukiswe inqubo yokukhiqiza. Lesi silinganiso sokulawula ikhwalithi yesikhathi sangempela sisiza ukuthola izinkinga ekukhiqizeni ngesikhathi, ukugwema ukukhiqizwa kwenani elikhulu lemikhiqizo engafanelekile, futhi sithuthukise ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

Kafushane, umshini wokuphonsa we-ingot wegolide ozenzakalelayo ngokuphelele ugqekeze ngempumelelo ibhodlela le-ingot elivamile ngokusebenzisa izinto ezintsha ezihlukahlukene nokuthuthukisa njengezinqubo zokukhiqiza ezizenzakalelayo, amasistimu asebenzayo okufudumeza nokupholisa, amasistimu okulawula anembe kakhulu, ukuthuthukiswa kwesikhunta nobuchwepheshe bokudlulisa, nokutholwa ku-inthanethi nokulawula ikhwalithi. Izuze ukusebenza kahle okuphezulu, ikhwalithi ephezulu, kanye ne-automation ekukhiqizeni i-ingots yensimbi eyigugu, ihlinzeka ngokusekela okuqinile kwezobuchwepheshe ekuthuthukiseni izimboni ezifana nokucwenga igolide.

Ungaxhumana nathi ngezindlela ezilandelayo:

WhatsApp: 008617898439424

I-imeyili:sales@hasungmachinery.com

Iwebhusayithi: www.hasungmachinery.com www.hasungcasting.com

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjiniyela bemishini etholakala eningizimu yeShayina, edolobheni elihle nelikhula ngokushesha kwezomnotho, iShenzhen. Le nkampani ingumholi kwezobuchwepheshe emkhakheni wemishini yokushisa nokukhipha izinsimbi eziyigugu kanye nemboni yezinto ezintsha.

Ulwazi lwethu oluqinile kubuchwepheshe bokuphonswa kwe-vacuum lusenza sikwazi ukukhonza amakhasimende ezimboni ukuze afake insimbi exutshwe kakhulu, i-platinum-rhodium alloy edingekayo nge-vacuum ephezulu, igolide nesiliva, njll.

Ucingo: +86 17898439424

I-imeyili: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Ikheli: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115