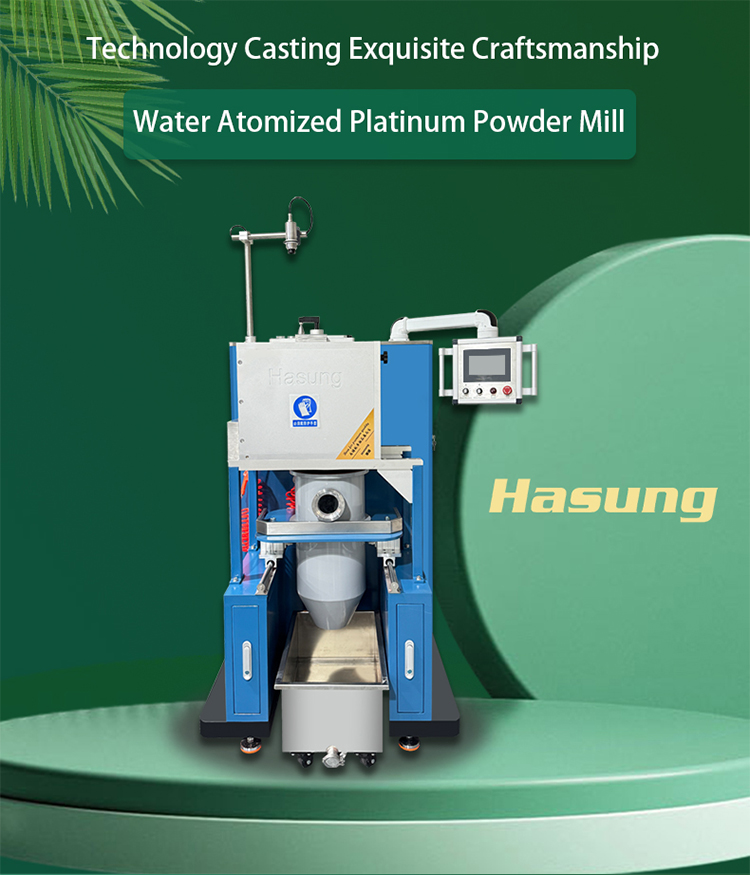

Qalabka Budada Atomization Biyaha ee Platinum

Habka wax-soo-saarka budada atomization-ka-sare ee biyaha waa nidaam soo ifbaxaya oo lagu sameeyay warshadaha birta budada sannadihii dhawaa. Waxay leedahay sifooyinka soo socda:

1. Wareegga wax soo saarka gaaban, isticmaalka tamarta yar, kharash yar, iyo waxtarka wax soo saarka sare;

2. Hawlgalka fudud, fudud ee tignoolajiyada, qalabka aan si sahlan loo oksijiin, heer sare oo otomaatig ah, shuban la'aan wasakhda, aashitada, xalalka alkali inta lagu jiro habka wax soo saarka, oo aan wasakhayn deegaanka;

3. Khasaarida birta waa mid aad u yar, alaabtuna way fududahay in dib loo warshadeeyo oo dib loo isticmaalo.

HS-MIP

Habka gaarka ah ayaa ah in daawaha (birta) lagu dhalaaliyo oo lagu sifeeyo foornada induction, iyo dareeraha dhalaalay waxaa lagu shubaa qolof dahaaran oo gala tuubo hage. Waqtigan xaadirka ah, qulqulka dareeraha cadaadiska sarreeya (ama socodka gaaska) ayaa laga buufiyaa saxanka buufinta, dareeraha birtana waxaa lagu burburiyaa dhibco aad u yaryar oo saameyn ah. Dhibcaha birta ahi way adkeeyaan oo ku dhacaan munaaradda atomization, ka dibna waxay ku dhacaan haanta ururinta budada si ay u ururiyaan. Burada budada ah ee la ururiyey waa la sifeeyaa oo fuuqbaxa, oo ugu dambeyntii la qalajiyey, la baadhay, la miisaamay, oo lagu baakadeeyey alaab dhammaatay.

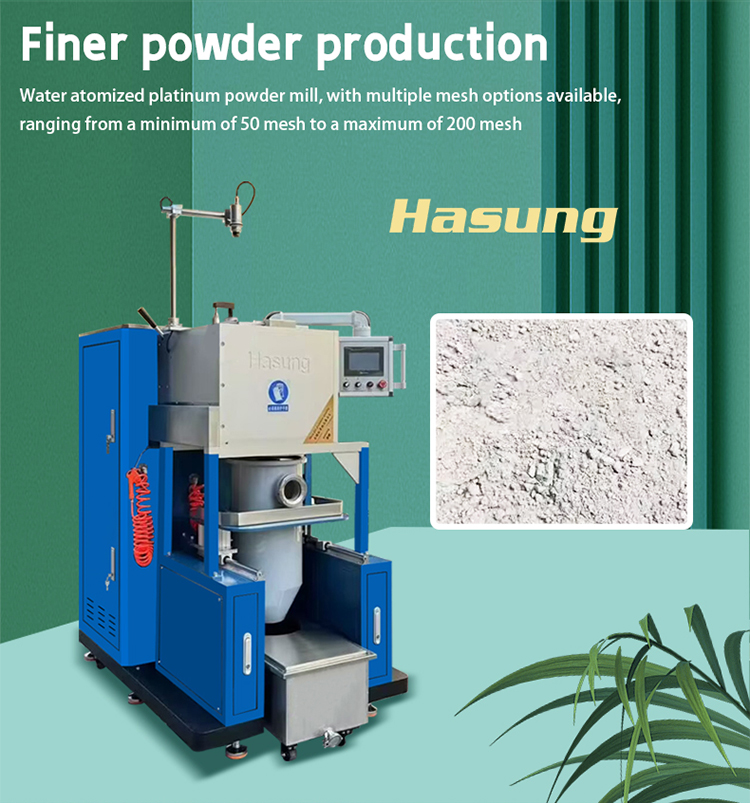

Budada birta ah ee ay soo saartay atomization biyaha cadaadiska sare waxay leedahay sifooyinka soo socda: qaab-dhismeedka aan caadiga ahayn ama ku dhawaad spherical, nadiif sare, content oxygen hooseeyo, xawaaraha solidification degdeg ah, iwm Waxaa si ballaaran loo isticmaalo berrinkii atomization ee budada biraha non-ferrous sida budada platinum, budada palladium, rhodium, budada birta, budada copper, ahama, budada birta iwm.

Atomization uumiga biyuhu dhab ahaantii waa habraac gaar ah oo atomization biyaha, kaas oo isticmaalaya cadaadiska xooggan ee diidmada ah ee ay dhaliso jet-biyoodka cadaadiska sare si uu u wado gaaska qolka atomization si uu uga qayb qaato atomization. Sababtoo ah faragelinta qadar badan oo gaas ah, heerka qaboojinta ee budada ayaa la dhimay, iyo qaab-dhismeedka budada ayaa la wanaajiyey. Sidaa darteed, qaybo yaryar iyo qaabab badan oo budada ah ayaa la soo saari karaa. Waqtigan xaadirka ah, waxaa inta badan loo isticmaalaa soo saarista budada birta ah iyo budada amorphous.

Qiyaasaha farsamada:

| Qaabka No. | HS-MIP2 | HS-MIP3 | HS-MIP4 | HS-MIP5 | HS-MIP10 |

| Voltage: | 380V, 50Hz, 3 Waji | ||||

| Awood | 15KW* 2 | 15KW* 2 | 15KW* 2 | 15KW* 2 | 30KW* 2 |

| Xawaaraha dhalaalka | 3-5 daqiiqo | 4-6 daqiiqo | 4-6 daqiiqo | ||

| Max. heerkulka | 2200C | ||||

| Heerkulka baaraha | Pyrometer infrared | ||||

| Biraha codsiga | Platinum, palladium, rhodium, birta aan lahayn, birta, dahabka, qalinka, naxaasta, alloys, iwm | ||||

| Farsamada kululaynta | Germany IGBT kululaynta induction | ||||

| Habka qaboojinta | Qaboojiyaha biyaha (si gaar ah ayaa loo iibiyaa) | ||||

| Isticmaalka biyaha qaboojinta | qiyaastii 90 ltr/min | ||||

| Cadaadiska biyaha qaboojinta | 1-3 bar | ||||

| Qaboojinta heerkulka gelitaanka biyaha. | 18-26 C | ||||

| Nidaamka xakamaynta | 7 "Weinview touch screen + Siemens PLC kontoroolka caqliga leh | ||||

| Cabbirka walxaha | 80#, 100#, 150#, 200# (hagaajin) | ||||

| Cabirka | 1020×1320 1680mm | 1220×1320 1880mm | |||

| Miisaanka | Qiyaastii 580kg | Qiyaastii 650kg | Qiyaastii 880kg | ||

Tilmaamaha bamka biyaha cadaadiska sarreeya:

| Voltage | 380V, 50Hz, 3 waji |

| Awood la qiimeeyay | 22 KW |

| Cadaadiska biyaha ee cadaadiska sarreeya | ilaa 23 Mpa |

| Qulqulka biyaha qaboojinta | qiyaastii 50 ltr/min |

| Cabirka | 1400*680*1340mm |

| Miisaanka | qiyaastii 620kg |

Tel: +86 17898439424

Iimayl: sales@hasungmachinery.comoo

WhatsApp: 0086 17898439424

Ciwaanka: No.11, Jidka 1aad ee Jinyuan, Beesha Heao, Yuanshan Street, Degmada Longgang, ShenZhen, Shiinaha 518115