UHasung ungumkhiqizi womshini wokubumba nokuncibilikisa izinsimbi eziyigugu ochwepheshe kusukela ngo-2014.

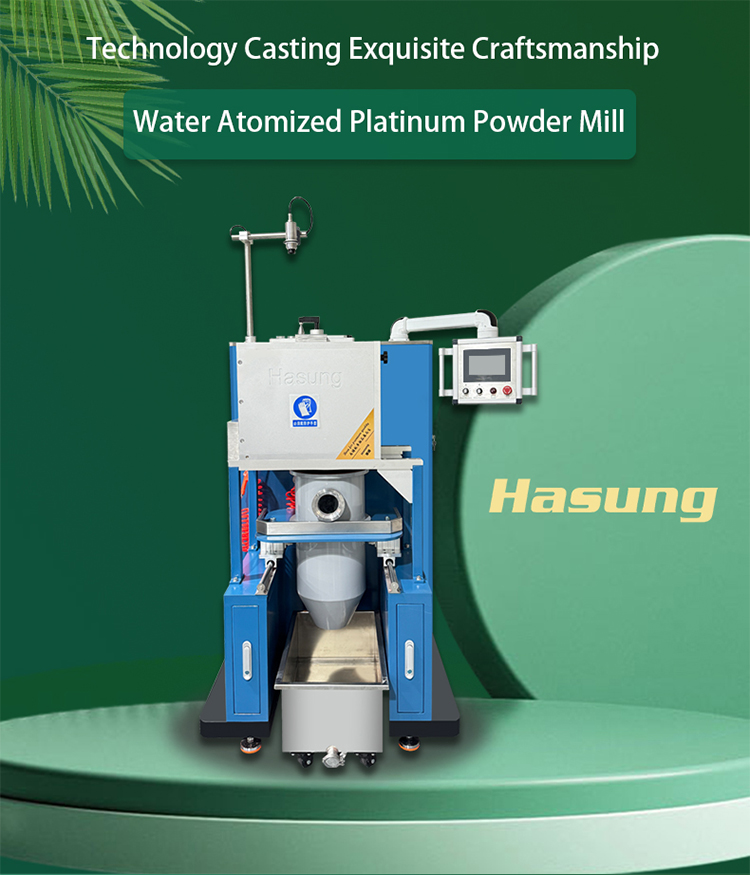

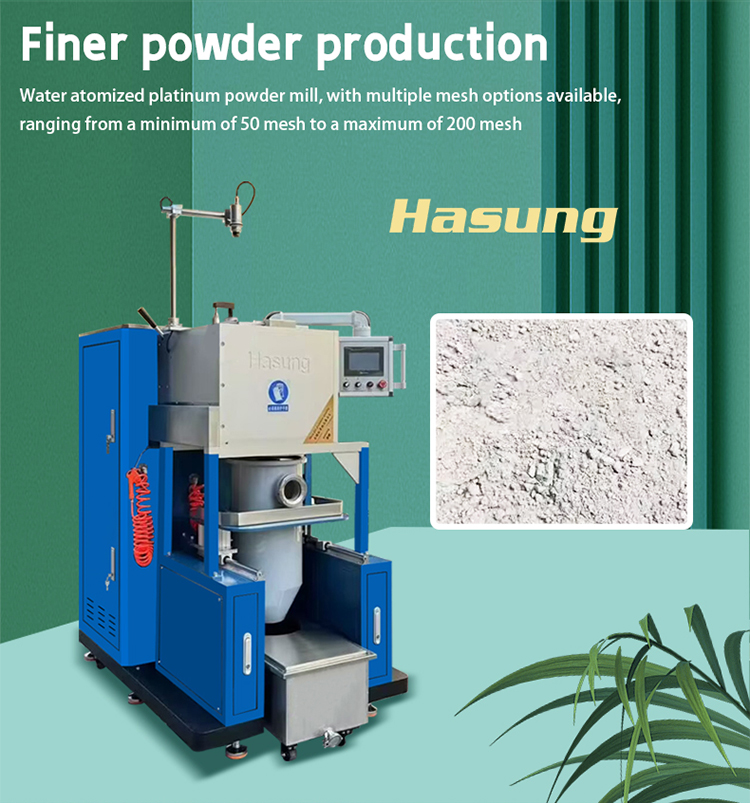

Imishini Yokwenza Uphoyidi Wamanzi E-Platinum

Indlela yokukhiqiza impuphu ye-atomization yamanzi enengcindezi ephezulu iyinqubo evelayo eyakhiwe embonini ye-powder metallurgy eminyakeni yamuva. Inezici ezilandelayo:

1. Umjikelezo omfushane wokukhiqiza, ukusetshenziswa kwamandla okuphansi, izindleko eziphansi, nokusebenza kahle kokukhiqiza okuphezulu;

2. Ukusebenza okulula, kulula ukuqonda ubuchwepheshe, izinto ezingasetshenziswa kalula nge-oxidized, izinga eliphezulu lokuzenzekelayo, akukho kukhishwa kwendle, i-asidi, isisombululo se-alkali ngesikhathi sokukhiqiza, futhi akukho ukungcoliswa kwemvelo;

3. Ukulahleka kwensimbi kuncane, futhi umkhiqizo kulula ukuwusebenzisa kabusha futhi uwusebenzise kabusha.

HS-MIP

Inqubo ethile yukuthi i-alloy (insimbi) iyancibilika futhi ihlanjululwe esithandweni sokungeniswa, futhi uketshezi lwensimbi oluncibilikisiwe luthululelwa ku-crucible insulated futhi lungena embhobho womhlahlandlela. Ngalesi sikhathi, ukugeleza koketshezi olunomfutho ophezulu (noma ukugeleza kwegesi) kufafazwa kupuleti lokufutha, futhi uketshezi lwensimbi luchotshozwa lube amaconsi amancane kakhulu ngomthelela. Amaconsi ensimbi ayaqina futhi awele kumbhoshongo we-atomization, bese ewela ethangini lokuqoqa impushana ukuze aqoqwe. I-powder slurry eqoqiwe iyahlungwa futhi iphelelwe amanzi, futhi ekugcineni yomiswe, ihlolwe, ikalwe, futhi ihlanganiswe emikhiqizweni ephelile.

Impushana yensimbi ekhiqizwa i-atomization yamanzi anomfutho ophezulu inezici ezilandelayo: i-morphology engavamile noma ecishe ibe yindilinga, ukuhlanzeka okuphezulu, okuqukethwe komoya-mpilo okuphansi, isivinini sokuqiniswa okusheshayo, njll. Isetshenziswa kabanzi emkhakheni we-atomization yezimpushana zensimbi ezingezona ezinsimbi ezifana ne-platinum powder, i-palladium powder, i-rhodium powder, i-iron powder, i-powder yethusi, njll.

I-atomization yomhwamuko wamanzi empeleni iyinqubo ekhethekile ye-atomization yamanzi, esebenzisa ukucindezela okunamandla okungalungile okukhiqizwa indiza yamanzi enomfutho ophezulu ukushayela igesi ekamelweni le-atomization ukuze libambe iqhaza ku-atomization. Ngenxa yokungenelela kwenani elikhulu legesi, izinga lokupholisa le-powder liyancishiswa, futhi i-morphology ye-powder ithuthukisiwe. Ngakho-ke, izinhlayiya ezicolekile kanye nezimo ezivamile zempushana zingakhiqizwa. Njengamanje, isetshenziselwa ikakhulukazi ukukhiqizwa kwe-stainless steel powder kanye ne-amorphous powder.

Amapharamitha wobuchwepheshe:

| Imodeli No. | HS-MIP2 | HS-MIP3 | HS-MIP4 | HS-MIP5 | HS-MIP10 |

| Amandla kagesi: | 380V,50Hz, 3 Isigaba | ||||

| Amandla | 15KW* 2 | 15KW* 2 | 15KW* 2 | 15KW* 2 | 30KW* 2 |

| Isivinini sokuncibilika | 3-5 imiz. | 4-6 imiz. | 4-6 imiz. | ||

| Ubukhulu. isikhashana. | 2200C | ||||

| Temp. umtshina | I-infrared pyrometer | ||||

| Izinsimbi zohlelo lokusebenza | iplatinum, i-palladium, i-rhodium, insimbi engagqwali, insimbi, igolide, isiliva, ithusi, ama-alloys, njll. | ||||

| Ubuchwepheshe bokushisa | I-Germany IGBT induction heat | ||||

| Indlela yokupholisa | I-water chiller (ithengiswa ngokwehlukana) | ||||

| Ukupholisa amanzi ukusetshenziswa | cishe. 90 amalitha/min. | ||||

| Ukupholisa ukucindezela kwamanzi | 1-3 ibha | ||||

| Izinga lokushisa lokupholisa lamanzi. | 18-26 C | ||||

| Isistimu yokulawula | 7" Isikrini sokuthinta se-Weinview + Isilawuli esihlakaniphile se-Siemens PLC | ||||

| Usayizi wezinhlayiya | 80#, 100#, 150#, 200# (lungisa.) | ||||

| Ubukhulu | 1020×1320 1680mm | 1220×1320 1880mm | |||

| Isisindo | Cishe 580kg | Cishe 650kg | Cishe 880kg | ||

Imininingwane yephampu yamanzi anomfutho ophezulu:

| Amandla kagesi | 380V, 50Hz, 3 isigaba |

| Amandla alinganiselwe | 22 KW |

| Umfutho wamanzi ophakeme | cishe 23 Mpa |

| Ukupholisa ukugeleza kwamanzi | cishe. 50 amalitha/min. |

| Ubukhulu | 1400*680*1340mm |

| Isisindo | cishe. 620kg |

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjiniyela bemishini etholakala eningizimu yeShayina, edolobheni elihle nelikhula ngokushesha kwezomnotho, iShenzhen. Le nkampani ingumholi kwezobuchwepheshe emkhakheni wemishini yokushisa nokukhipha izinsimbi eziyigugu kanye nemboni yezinto ezintsha.

Ulwazi lwethu oluqinile kubuchwepheshe bokuphonswa kwe-vacuum lusenza sikwazi ukukhonza amakhasimende ezimboni ukuze afake insimbi exutshwe kakhulu, i-platinum-rhodium alloy edingekayo nge-vacuum ephezulu, igolide nesiliva, njll.

Ucingo: +86 17898439424

I-imeyili: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Ikheli: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115