Cov Khoom Siv Platinum Water Atomization Hmoov

Txoj kev siv dej siab atomization hmoov yog cov txheej txheem tsim tawm hauv cov hmoov hlau metallurgy hauv xyoo tas los no. Nws muaj cov yam ntxwv hauv qab no:

1. Lub voj voog luv luv, kev siv hluav taws xob tsawg, tus nqi qis, thiab kev ua haujlwm siab;

2. Kev ua haujlwm yooj yim, yooj yim rau kev siv thev naus laus zis, cov ntaub ntawv tsis yooj yim oxidized, qib siab ntawm automation, tsis muaj dej paug, kua qaub, alkali tov thaum lub sij hawm tsim khoom, thiab tsis muaj kuab paug rau ib puag ncig;

3. Hlau poob yog tsawg, thiab cov khoom yog ib qho yooj yim rau recycle thiab rov siv dua.

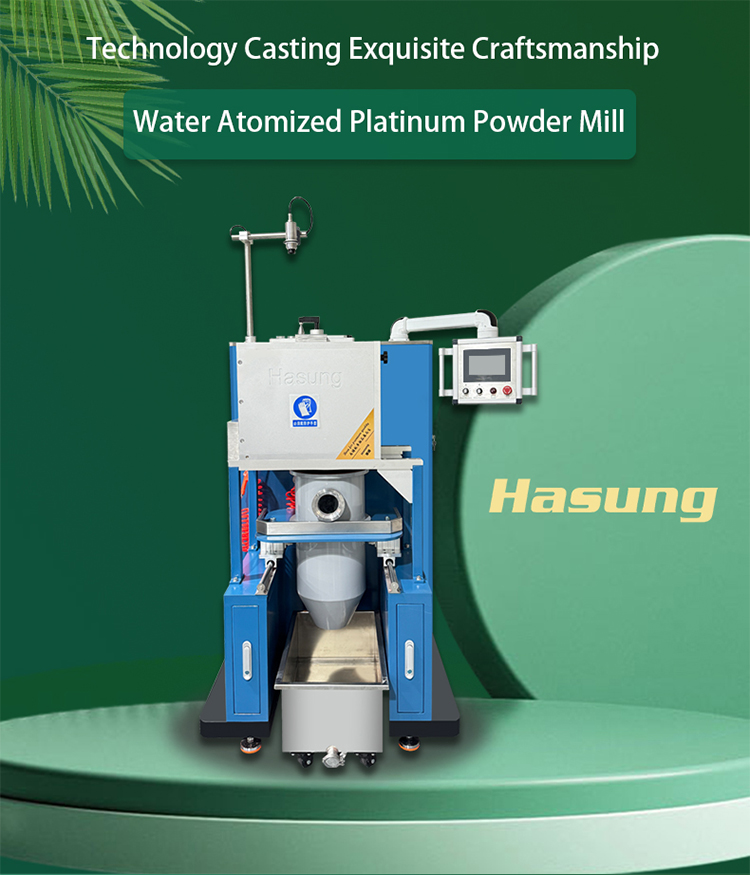

HS-MIP

Cov txheej txheem tshwj xeeb yog tias cov hlau (hlau) yog melted thiab refined nyob rau hauv ib tug induction rauv, thiab cov melted hlau kua yog poured rau hauv ib tug insulated crucible thiab nkag mus rau hauv ib tug coj yeeb nkab. Lub sijhawm no, cov kua dej siab siab (lossis cov roj ntws) yog txau los ntawm lub phaj tsuag, thiab cov kua hlau yog crushed rau hauv cov tee me me los ntawm kev cuam tshuam. Cov hlau tee dej khov kho thiab poob rau hauv cov atomization ntauwd, thiab tom qab ntawd poob rau hauv cov hmoov ntim tank rau kev sau. Cov hmoov slurry sau tau lim thiab lub cev qhuav dej, thiab thaum kawg qhuav, tshuaj xyuas, hnyav, thiab ntim rau hauv cov khoom tiav.

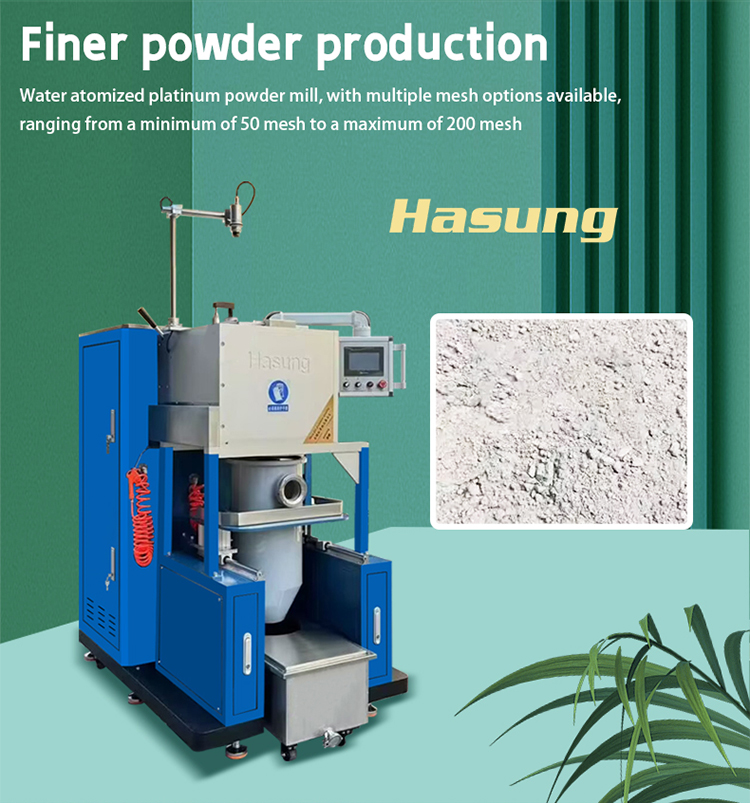

Cov hmoov hlau ua los ntawm cov dej siab atomization muaj cov yam ntxwv nram qab no: tsis xwm yeem los yog ze li ntawm tus kheej kheej morphology, siab purity, tsis tshua muaj oxygen cov ntsiab lus, ceev solidification ceev, thiab lwm yam. Nws yog dav siv nyob rau hauv lub teb ntawm atomization ntawm non-ferrous hlau hmoov xws li platinum hmoov, palladium hmoov, rhodium hmoov, hlau hmoov, tooj liab hmoov, stainless hlau hmoov, thiab lwm yam.

Dej vapor atomization tiag tiag yog cov txheej txheem dej tshwj xeeb atomization, uas siv lub zog tsis zoo uas tsim los ntawm lub dav hlau dej siab kom tsav cov roj hauv lub atomization chamber los koom rau hauv atomization. Vim muaj kev cuam tshuam ntawm cov pa roj ntau, qhov txias ntawm cov hmoov yog txo, thiab cov morphology ntawm cov hmoov zoo tuaj. Yog li ntawd, cov khoom me me thiab cov duab zoo li qub tuaj yeem tsim tau. Tam sim no, nws yog tsuas yog siv rau zus tau tej cov stainless hlau hmoov thiab amorphous hmoov.

Technical parameters:

| Qauv No. | HS-MIP2 | HS-MIP3 | HS-MIP4 | HS-MIP5 | HS-MIP10 |

| Voltage: | 380V, 50Hz, 3 theem | ||||

| Hwj chim | 15 KW * 2 | 15 KW * 2 | 15 KW * 2 | 15 KW * 2 | 30 KW * 2 |

| Melting ceev | 3-5 feeb. | 4-6 feeb. | 4-6 feeb. | ||

| Max. temp. | 2200C | ||||

| Temp. ntes | Pyrometer infrared | ||||

| Kev siv hlau | platinum, palladium, rhodium, stainless hlau, hlau, kub, nyiaj, tooj liab, alloys, thiab lwm yam | ||||

| Cua sov tshuab | Lub teb chaws Yelemees IGBT induction cua sov | ||||

| Txoj kev ua kom txias | Dej chiller (muag nyias) | ||||

| Kev siv dej txias | kwv yees. 90 l / min | ||||

| Cov dej txias txias | 1-3 bar | ||||

| Dej txias inlet temp. | 18-26 C | ||||

| Tswj qhov system | 7" Weinview kov npo + Siemens PLC ntse tswj | ||||

| Particle loj | 80 #, 100 #, 150 #, 200 # (kho.) | ||||

| Qhov ntev | 1020 × 1320 1680mm | 1220 × 1320 1880mm | |||

| Qhov hnyav | Kwv yees li 580 kg | Kwv yees li 650 kg | Kwv yees li 880 kg | ||

High pressure dej twj tso kua mis specifications:

| Qhov hluav taws xob | 380V, 50Hz, 3 theem |

| Rated zog | 22 KW |

| High-pressure dej siab | txog 23 Mpa |

| Cov dej txias txias | kwv yees. 50 liters / min. |

| Qhov ntev | 1400 * 680 * 1340 hli |

| Qhov hnyav | kwv yees. 620kg ua |

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115