Hasung inyanzvi yekugadzira michina yekukanda nekunyungudutsa simbi dzinokosha kubvira muna 2014.

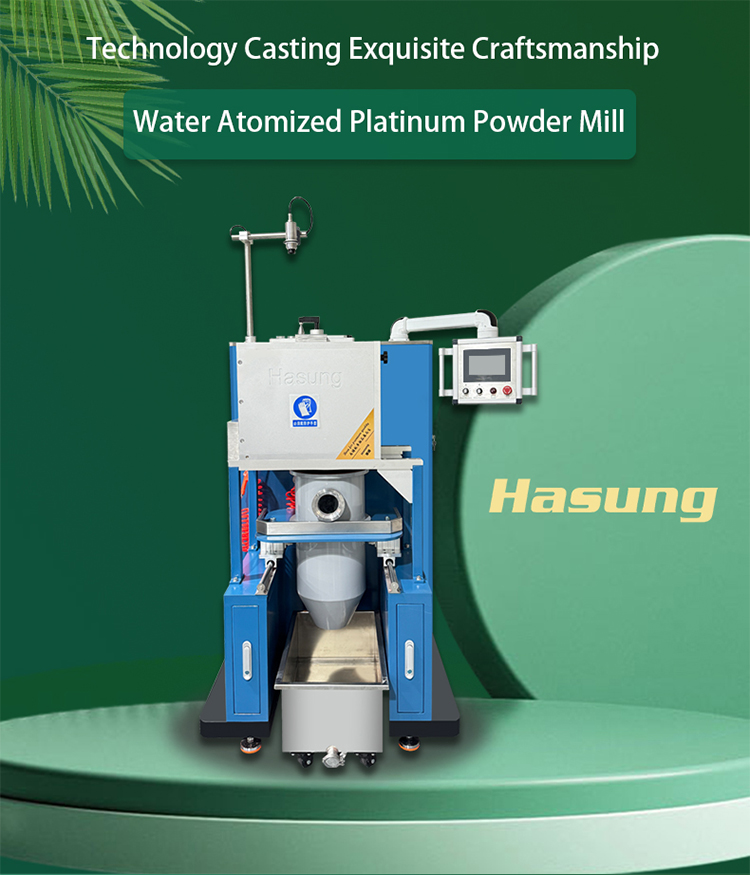

Midziyo yePlatinum Water Atomization Powder

Iyo yakakwira-kudzvanywa kwemvura atomization poda nzira yekugadzira inzira iri kubuda yakagadziridzwa muindasitiri yehupfu simbi mumakore achangopfuura. Iine maitiro anotevera:

1. Kutenderera kupfupi kwekugadzira, kuderera kwesimba rekushandisa, kudhura kwakaderera, uye kugona kukuru kwekugadzira;

2. Kushanda kuri nyore, kuri nyore kugona tekinoroji, zvinhu zvisiri nyore oxidized, yakakwirira dhigirii otomatiki, hapana kubuda kwetsvina, asidhi, alkali mhinduro panguva yekugadzira, uye hapana kusvibiswa kune zvakatipoteredza;

3. Kurasika kwesimbi kushoma, uye chigadzirwa chiri nyore kudzokorora uye kushandisa zvakare.

HS-MIP

Iyo chaiyo nzira ndeyokuti alloy (simbi) yakanyungudutswa uye inonatswa muchoto chekupinza, uye iyo yakanyungudutswa yesimbi mvura inodururwa muinsulated crucible uye inopinda mupombi inotungamira. Panguva ino, kuyerera kwemvura yakakwira (kana kuyerera kwegasi) inopfapfaidzwa kubva mundiro yekupfapfaidza, uye mvura yesimbi inopwanywa kuita madonhwe madiki zvakanyanya. Madonhwe esimbi anoomesa uye anowira mushongwe yeatomization, uye obva awira muhupfu hwekuunganidza tangi yekuunganidza. Iyo yakaunganidzwa poda slurry inosefa uye inopera mvura, uye pakupedzisira yakaomeswa, yakaongororwa, inoyerwa, uye inoiswa muzvigadzirwa zvakapedzwa.

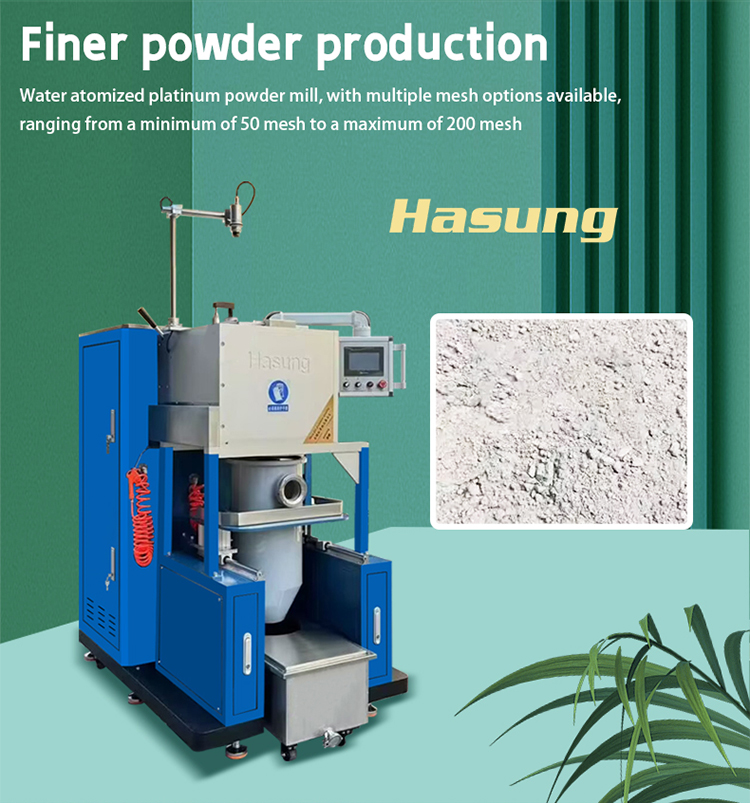

Iyo simbi yehupfu inogadzirwa ne-high-pressure water atomization ine maitiro anotevera: irregular kana inenge spherical morphology, kuchena kwepamusoro, kuderera kweokisijeni, kutsanya kusimba kwekukurumidza, etc. Inoshandiswa zvakanyanya mumunda weatomization yehupfu hwesimbi husina-ferrous yakadai seplatinum powder, palladium powder, rhodium powder, iron powder, copper, etc.

Mvura vapor atomization ndeyechokwadi yakakosha yemvura atomization process, iyo inoshandisa iyo yakasimba yakashata kudzvanywa inogadzirwa ne-high-pressure yemvura jet kutyaira gasi mukamuri yeatomization kutora chikamu muatomization. Pamusana pekupindira kwehuwandu hwegesi, kutonhora kwehupfu kunoderedzwa, uye morphology yehupfu inovandudzwa. Naizvozvo, zvidimbu zvakapfava uye mamwe maumbirwo ehupfu anogona kugadzirwa. Parizvino, inonyanya kushandiswa pakugadzirwa kwesimbi isina tsvina poda uye amorphous powder.

Technical parameters:

| Muenzaniso Nha. | HS-MIP2 | HS-MIP3 | HS-MIP4 | HS-MIP5 | HS-MIP10 |

| Voltage: | 380V, 50Hz, 3 Chikamu | ||||

| Simba | 15KW* 2 | 15KW* 2 | 15KW* 2 | 15KW* 2 | 30KW* 2 |

| Kunyunguduka kumhanya | 3-5 min. | 4-6 min. | 4-6 min. | ||

| Max. temp. | 2200C | ||||

| Temp. detector | Infrared pyrometer | ||||

| Application metals | platinamu, palladium, rhodium, simbi isina tsvina, simbi, goridhe, sirivha, mhangura, alloys, nezvimwe. | ||||

| Kupisa tekinoroji | Germany IGBT induction heat | ||||

| Kutonhodza nzira | Mvura chiller (inotengeswa zvakasiyana) | ||||

| Kutonhodza kushandiswa kwemvura | approx. 90 ltr./min. | ||||

| Kutonhora kwemvura inotonhora | 1-3bar | ||||

| Kutonhora kwemvura inopinza tembiricha. | 18-26 C | ||||

| Kudzora system | 7" Weinview touch screen + Siemens PLC yakangwara kutonga | ||||

| Chikamu saizi | 80#, 100#, 150#, 200# (gadzirisa.) | ||||

| Dimensions | 1020×1320 1680mm | 1220×1320 1880mm | |||

| Kurema | Zvinenge 580kg | Anenge 650kg | Anenge 880kg | ||

High pressure water pump specifications:

| Voltage | 380V, 50Hz, 3 chikamu |

| Rated power | 22 KW |

| High-pressure water pressure | anenge 23 Mpa |

| Kuyerera kwemvura inotonhorera | approx. 50 ltr./min. |

| Dimensions | 1400*680*1340mm |

| Kurema | approx. 620kg |

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ikambani yeinjiniya yemakanika iri kumaodzanyemba kweChina, muguta rakanaka uye riri kukura nekukurumidza muhupfumi, Shenzhen. Kambani iyi inotungamira muhunyanzvi hwetekinoroji munharaunda yemidziyo yekudziyisa nekukanda simbi dzinokosha neindasitiri yezvinhu zvitsva.

Ruzivo rwedu rwakasimba muhunyanzvi hwekukanda vacuum runotigonesawo kushandira vatengi vemaindasitiri kugadzira simbi ine musanganiswa wakawanda, platinum-rhodium alloy inodiwa ne musanganiswa wakawanda, goridhe nesirivha, nezvimwewo.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Kero: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115