Hasung Silver Block Casting Ntau Lawm Kab: Ua tau zoo thiab muaj tseeb Silver Block Manufacturing Solution

Hasung silver block casting ntau lawm kab txais cov khoom siv automation siab heev kom ntseeg tau tias muaj txiaj ntsig thiab ua haujlwm siab los ntawm cov khoom siv nyiaj mus rau cov nyiaj tiav. Tag nrho cov kab ntau lawm suav nrog plaub cov cuab yeej tseem ceeb: granulator, lub tshuab nqus tsev ingot casting, embossing tshuab, thiab serial tooj npav tshuab. Txhua qhov txuas tau raug kho kom zoo los xyuas kom meej qhov zoo, qhov tseeb, thiab traceability ntawm cov nyiaj blocks.

1. Granulator : meej npaj ntawm cov nyiaj hais

Kev Ua Haujlwm: Cov txheej txheem nyiaj raw cov ntaub ntawv mus rau hauv cov khoom sib npaug kom ntseeg tau tias muaj kev sib xws hauv kev nruam tom ntej.

Qhov zoo:

① Efficiency thiab txuag hluav taws xob

Los ntawm kev siv cov ntsia hlau optimized tsim thiab electromagnetic cua sov tshuab, nws txuag 15% mus rau 30% zog piv rau cov tsoos granulators, thaum tswj cov zis siab thiab txo cov nqi ntau lawm.

② Uniform thiab ruaj khov hais

Nruab nrog precision pwm thiab ntau cov hniav txiav tshuab, kom ntseeg tau tias qhov loj me me (nrog qhov yuam kev ntawm ± 0.1mm), haum rau kev lag luam uas xav tau siab precision, xws li tshuaj thiab khoom noj.

③ Intelligent automation tswj

PLC + kov npo ua haujlwm, saib xyuas lub sijhawm ntawm qhov kub thiab txias, ceev thiab lwm yam tsis zoo, tsis siv neeg lub tswb nrov, txo cov kev cuam tshuam ntawm phau ntawv, thiab txhim kho kev tsim khoom.

④ Kev ruaj khov thiab yooj yim los tswj

Cov khoom tseem ceeb (ntsia hlau, cov thoob) raug kho nrog cov khoom hnav-tiv taus lossis coatings rau lub neej ua haujlwm ntev. Cov qauv tsim qauv ua rau kev saib xyuas yooj yim dua thiab txo qis sijhawm.

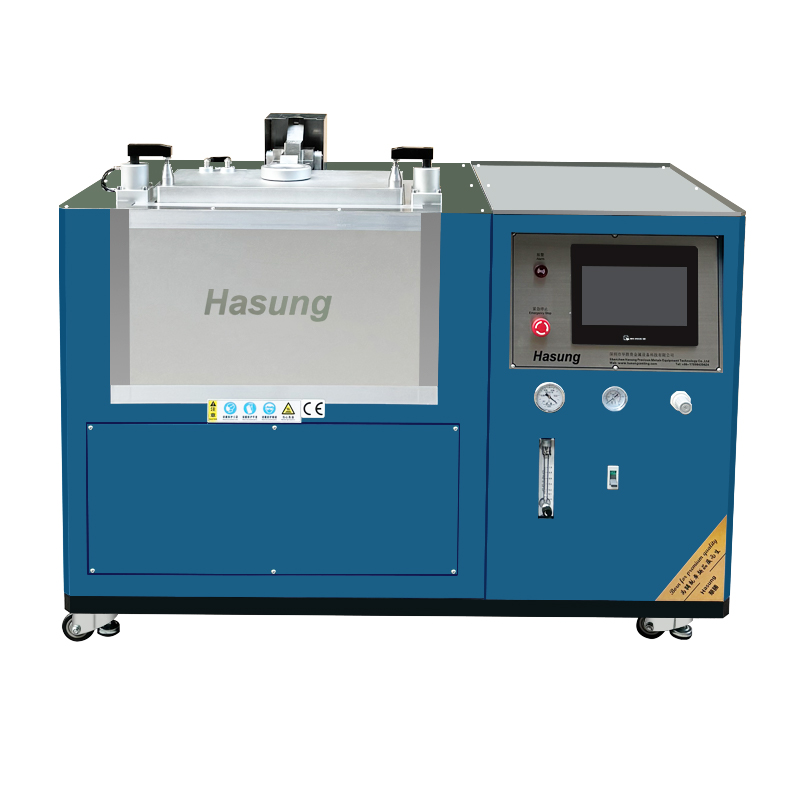

2. Nqus Ingot Casting Tshuab : Tsim High Purity Silver Blocks

Muaj nuj nqi: Melt thiab cam khwb cia nyiaj hais rau hauv du, impurity free silver blocks, kom ntseeg tau siab ceev thiab nto smoothness.

Qhov zoo:

① High purity ingot

Txais siv lub tshuab nqus tsev melting, zoo txo oxidation thiab impurity mixing, haum rau casting high-purity hlau xws li titanium, zirconium, thiab tshwj xeeb alloys, kom ruaj khov khoom.

② Uniform crystalline qauv

Lub kaw lus tswj qhov kub thiab txias, ua ke nrog cov kev taw qhia kev sib koom ua ke, ua kom zoo dua cov qoob loo sab hauv thiab cov qauv zoo ib yam ntawm cov ingot, txo cov kev sib cais, thiab txhim kho kev ua haujlwm tom ntej.

③ Efficiency thiab txuag hluav taws xob

Ua kom zoo rau kev tsim cov cua sov thiab cua txias, txo kev siv hluav taws xob los ntawm 20% mus rau 30% piv rau cov khoom siv hluav taws xob ib txwm muaj, thaum tswj kev ua haujlwm siab ntau lawm (xws li ib lub cub tawg ua haujlwm txog li 1-5 tons).

④ Automated ntse tswj

PLC + human-machine interface (HMI) saib xyuas qhov tsis xws li lub tshuab nqus tsev kawm ntawv, qhov kub thiab txias, siab hauv lub sijhawm tiag tiag, txhawb nqa cov ntaub ntawv kaw thiab cov txheej txheem tracing, txo cov tib neeg yuam kev, thiab ua haujlwm yooj yim dua.

3. Embossing tshuab: high-precision imprinting

Muaj nuj nqi: Imprint customized qauv xws li hom logo, qhov hnyav, purity, thiab lwm yam nyob rau saum npoo ntawm nyiaj blocks.

Qhov zoo:

① High precision embossing

Cov cuab yeej muaj kev tswj xyuas qhov siab thiab kev ua haujlwm ruaj khov. Thaum imprinting silver blocks, cov ntsiab lus xws li cov qauv thiab cov cim tuaj yeem nthuav tawm kom pom tseeb nrog qhov tseeb qhov tseeb, kom ntseeg tau qhov sib xws ntawm cov nyiaj thaiv kev luam ntawv. Piv txwv li, thaum ua kev nco txog cov nyiaj npib nyiaj npib, cov qauv zoo kuj tuaj yeem raug kho kom raug.

② Ua haujlwm tau zoo

Nws tuaj yeem ua tiav cov txheej txheem nyiaj stamping sai sai, ua kom lub sijhawm ua haujlwm ntawm cov nyiaj blocks ntawm tus kheej piv rau cov txheej txheem ib txwm muaj, txhim kho batch ntau lawm efficiency, pab cov lag luam xa cov xaj hauv lub sijhawm luv luv, thiab ua tau raws li kev lag luam xav tau rau cov khoom siv nyiaj.

③ ruaj khov zoo

Lub siab thaum lub sij hawm embossing txheej txheem yog uniform thiab kev ua haujlwm yog ruaj khov. Cov tsos zoo ntawm cov nyiaj thaiv tom qab embossing yog qhov zoo, thiab nws tsis yooj yim rau deformation, kev puas tsuaj thiab lwm yam teeb meem, uas txhim kho cov txiaj ntsig ntawm cov khoom siv nyiaj thiab txo tus nqi poob los ntawm cov khoom puas.

④ Kev hloov pauv ntau yam

Muaj peev xwm hloov mus rau qhov sib txawv specifications thiab cov duab ntawm cov nyiaj thaiv embossing, txawm tias nws yog cov nyiaj me me, cov khoom siv nyiaj zoo li cov hniav nyiaj hniav kub, los yog cov khoom siv nyiaj ib txwm muaj, cov kev txwv tuaj yeem hloov kho rau embossing, flexibly ntsib ntau yam kev xav tau.

4. Serial number marking tshuab: xyuas kom meej traceability

Muaj nuj nqi: Laser engraving cim serial tooj, ntau lawm hnub, batch tooj, thiab lwm yam ntaub ntawv ntawm nyiaj blocks.

Qhov zoo:

① Muaj tseeb thiab meej

Nws tuaj yeem kho cov lej lej kom raug, nrog cov cwj nrag zoo nkauj thiab txawm tias qhov tob ntawm cov cim thiab cov lej. Txawm tias nyob rau hauv lub sij hawm ntev siv thiab complex ib puag ncig, cov cim tsis yooj yim plooj, kom ntseeg tau qhov tseeb ntawm serial tooj paub thiab pab txhawb cov khoom traceability tswj.

② Yooj yim rau kev khiav lag luam

Qhov kev teeb tsa ntawm cov cuab yeej khawm yog tsim nyog, ua ke nrog kev tswj hwm yooj yim. Cov neeg ua haujlwm tuaj yeem pib tau yooj yim tom qab kev cob qhia yooj yim, thiab tuaj yeem teeb tsa cov ntsiab lus thiab cov cim, txo qhov kev ua haujlwm thiab cov nqi zog.

③ Ua haujlwm zoo thiab ruaj khov

Cov txheej txheem kev kos npe yog coherent, muaj peev xwm ua kom tiav cov lej cim tau sai, thiab ua haujlwm ruaj khov nrog ob peb lub sijhawm ua haujlwm tsis ua haujlwm, txhim kho kev ua haujlwm ntawm cov khoom lag luam kos npe thiab pab txhawb kev sib tw ntau lawm.

④ Kev hloov pauv dav dav

Nws tuaj yeem hloov kho mus rau ntau yam ntaub ntawv thiab cov duab ntawm cov khoom ua haujlwm rau kev kos, thiab tuaj yeem ruaj khov khij lub tiaj thiab me me nkhaus workpieces ua los ntawm cov hlau thiab qee cov ntaub ntawv tsis-hlau, ua tau raws li cov kev xav tau ntawm cov khoom sib txawv.

Kev ua tau zoo ntawm cov kab ntau lawm

✅ Cov txheej txheem automated tag nrho: txo cov kev cuam tshuam ntawm phau ntawv thiab txo qhov kev pheej hmoo ntawm kev ua yuam kev.

✅ Kev tswj xyuas qhov tseeb: kev tshuaj xyuas nruj ntawm txhua theem kom ntseeg tau tias qhov purity ntawm cov nyiaj blocks yog ≥ 99.99%.

✅ Saj zawg zog thiab scalable: adjustable tsis hloov mus rau txawv specifications (1kg / 5oz / 100g, thiab lwm yam.) ntawm nyiaj block ntau lawm.

✅ Ua raws li cov qauv thoob ntiaj teb: ua tau raws li kev lag luam ntawv pov thawj raws li ISO.

xaus

Hasung silver block casting ntau lawm kab tau dhau los ua qhov kev daws teeb meem hauv kev lag luam hlau muaj txiaj ntsig, ua tsaug rau kev ua haujlwm zoo ntawm cov granulator, kev ua tiav ntawm lub tshuab nqus tsev ingot casting, kev txheeb xyuas meej ntawm lub tshuab embossing, thiab tag nrho traceability ntawm serial tooj npav tshuab. Txawm hais tias kev nqis peev hauv cov nyiaj tuav, cov khoom siv nyiaj, lossis cov khoom siv siab kawg, cov kab ntau lawm tuaj yeem muab cov khoom lag luam ruaj khov thiab zoo siab.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115