Hasung ke Moetsi oa Mechini ea ho Qhibilihisa le ho Fokotsa Tšepe ea Bohlokoa ho tloha ka 2014.

Mohala oa Tlhahiso ea Hasung Silver Block Casting: Tharollo e Sebetsang le e Nepahetseng ea Silver Block Manufacturing Solution

Mohala oa tlhahiso ea silevera ea Hasung o sebelisa lisebelisoa tse tsoetseng pele tsa othomathike ho netefatsa tlhahiso e sebetsang hantle le e phahameng haholo ho tloha ho thepa e tala ea silevera ho isa ho li-block tsa silevera tse felileng. Mohala oohle oa tlhahiso o kenyelletsa lisebelisoa tse 'nè tsa mantlha: granulator, vacuum ingot casting machine, embossing machine, le serial number marking machine. Khokahano e 'ngoe le e' ngoe e ntlafalitsoe ho netefatsa boleng, ho nepahala le ho lateloa ha li-block tsa silevera.

1. Granulator : tokisetso e nepahetseng ea likaroloana tsa silevera

Mosebetsi: Etsa lisebelisoa tse tala tsa silevera ka likaroloana tsa boholo bo lekanang ho netefatsa ho ts'oana ha ho etsoa ka morao.

Melemo:

① E sebetsa hantle ebile e baballa matla

Ka ho amohela moralo o ntlafalitsoeng oa screw le theknoloji ea ho futhumatsa ka motlakase, e boloka matla a 15% ho isa ho 30% ha e bapisoa le li-granulator tsa setso, ha e ntse e boloka tlhahiso e phahameng le ho fokotsa litšenyehelo tsa tlhahiso.

② Likaroloana tse sa tšoaneng le tse tsitsitseng

E na le liforomo tse nepahetseng le mekhoa e mengata ea ho itšeha ka lehare, ho netefatsa boholo ba likaroloana tse tsitsitseng (ka phoso ea ± 0.1mm), e loketseng liindasteri tse hlokang ho nepahala ho phahameng, tse kang meriana le lijo.

③ Taolo ea boiketsetso e bohlale

PLC + touch screen ts'ebetso, ho lekola mocheso ka nako ea nnete, lebelo le li-parameter tse ling, alamo ea phoso ea othomathiki, ho fokotsa ho kenella ka letsoho, le ho ntlafatsa katleho ea tlhahiso.

④ E tšoarella ebile ho bonolo ho e hlokomela

Likarolo tsa bohlokoa (li-screws, barrel) li tšoaroa ka li-alloys tse sa tsitsang kapa liaparo bakeng sa bophelo bo bolelele ba tšebeletso. Moralo oa modular o etsa hore tlhokomelo e be bonolo haholoanyane mme e fokotsa nako ea ho theoha.

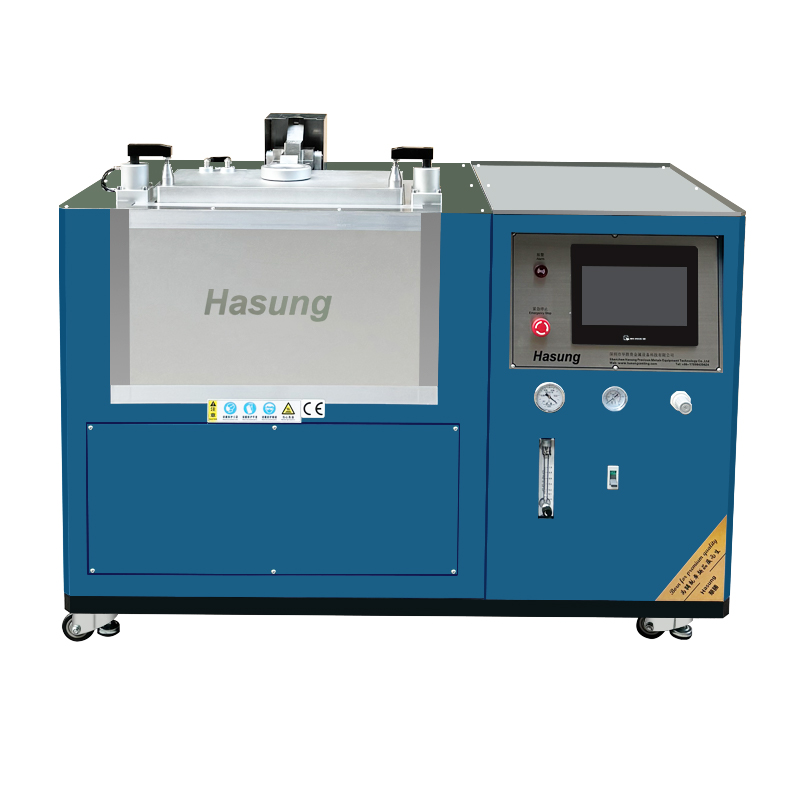

2. Mochini oa Vacuum Ingot Casting : Ho theha Li-blocks tsa Silver tse Hloekileng

Mosebetsi: Qhibiliha le ho lahlela likaroloana tsa silevera ka har'a li-block tsa silevera tse boreleli, tse sa hloekang, ho netefatsa hore ho na le sekhahla se phahameng le boreleli holim'a metsi.

Melemo:

① Ingot ea bohloeki bo phahameng

Ho amohela theknoloji ea ho qhibiliha ha vacuum, ka katleho ho fokotsa oxidation le ho kopanya litšila, tse loketseng ho lahla litšepe tse hloekileng tse kang titanium, zirconium le li-alloys tse khethehileng, ho netefatsa thepa e tsitsitseng ea thepa.

② Sebopeho sa kristale se tšoanang

Mokhoa o nepahetseng oa ho laola mocheso, o kopantsoeng le theknoloji ea ho tiisa tataiso, e ntlafatsa boholo ba lijo-thollo tse ka hare le sebopeho se ts'oanang sa ingot, e fokotsa karohano, 'me e ntlafatsa ts'ebetso ea ts'ebetso e latelang.

③ E sebetsa hantle ebile e baballa matla

Ntlafatsa moralo oa litsamaiso tsa ho futhumatsa le ho pholisa, ho fokotsa tšebeliso ea matla ka 20% ho isa ho 30% ha e bapisoa le lisebelisoa tsa khale tsa ingot, ha u ntse u boloka ts'ebetso e phahameng ea tlhahiso (joalo ka sebopi se le seng sa ho sebetsa ho fihlela ho lithane tse 1-5).

④ Taolo e bohlale e itirisang

PLC + human-machine interface (HMI) e lekola liparamente tse kang vacuum degree, mocheso, khatello ka nako ea nnete, e ts'ehetsa ho rekota data le ts'ebetso ea ts'ebetso, e fokotsa liphoso tsa batho, 'me e etsa hore ts'ebetso e be bonolo haholoanyane.

3. Mochine oa ho khabisa: ho hatisa mokhoa o phahameng oa ho nepahala

Mosebetsi: Hatisa lipaterone tse ikhethileng joalo ka logo ea brand, boima, bohloeki, joalo-joalo holim'a li-blocks tsa silevera.

Melemo:

① Mongolo o hlakileng haholo

Thepa e na le taolo e nepahetseng ea khatello le sebopeho se tsitsitseng sa ts'ebetso. Ha u hatisa li-blocks tsa silevera, lintlha tse kang lipaterone le matšoao li ka hlahisoa ka mokhoa o hlakileng ka ho nepahala ha maemo a holimo, ho netefatsa ho ts'oana ha khatiso ea block block. Ka mohlala, ha u etsa li-blocks tsa silevera tsa sehopotso, mekhoa e metle e ka boela ea tsosolosoa ka nepo.

② Mosebetsi oa sekolo o sebetsang hantle

E ka phethela ka potlako ts'ebetso ea litempe tsa silevera, ea khutsufatsa nako ea ts'ebetso ea li-block tsa silevera ha e bapisoa le mekhoa ea setso, ea ntlafatsa ts'ebetso ea tlhahiso ea batch, ea thusa likhoebo ho fana ka litaelo ka nako e khuts'oane, le ho fihlela tlhoko ea mmaraka ea lihlahisoa tsa silevera.

③ Boleng bo tsitsitseng

Khatello nakong ea ts'ebetso ea ho khabisa e tšoana hantle 'me ts'ebetso e tsitsitse. Ponahalo ea boleng ba silevera ka mor'a ho khabisa e ntle, 'me ha e na tšekamelo ea ho senyeha, ho senya le mathata a mang, e leng ho ntlafatsang lihlahisoa tsa lihlahisoa tsa silevera le ho fokotsa tahlehelo ea litšenyehelo e bakoang ke lihlahisoa tse nang le bokooa.

④ Ho ikamahanya le maemo

E khona ho ikamahanya le litlhaloso le libopeho tse fapaneng tsa li-block embossing, ekaba li-bars tse nyane tsa silevera, likarolo tse rarahaneng tsa mabenyane a silevera, kapa li-blocks tse tloaelehileng tsa silevera, li-parameter li ka fetoloa bakeng sa ho khabisa, ho kopana le litlhoko tse fapaneng tsa tlhahiso.

4. Mochini oa ho tšoaea nomoro ea serial: Etsa bonnete ba hore ho na le traceability

Mosebetsi: Laser e ngola linomoro tse ikhethang tsa serial, matsatsi a tlhahiso, linomoro tsa batch, le lintlha tse ling ka li-block tsa silevera.

Melemo:

① E nepahetse ebile e hlakile

E ka khutlisetsa linomoro tsa serial ka nepo, ka liropo tse makhethe esita le botebo ba litlhaku le linomoro. Esita le ts'ebelisong ea nako e telele le tikolohong e rarahaneng, matšoao ha a fokotsehe habonolo, ho netefatsa bonnete ba temoho ea nomoro ea serial le ho nolofatsa taolo ea traceability ea sehlahisoa.

② Ho bonolo ho sebetsa

Sebopeho sa likonopo tsa lisebelisoa sea utloahala, se kopantsoe le mokhoa o bonolo oa ho laola. Basebeletsi ba ka qala habonolo ka mor'a koetliso e bonolo, 'me ba ka potlakela ho beha litaba tsa ho tšoaea le litekanyetso, ho fokotsa moeli oa ts'ebetso le litšenyehelo tsa basebetsi.

③ E sebetsa hantle ebile e tsitsitse

Ts'ebetso ea ho tšoaea e momahane, e khona ho phethela kapele ho tšoaea linomoro tsa serial, 'me e tsamaea ka botsitso ka liphoso tse' maloa tsa nako e telele tsa mosebetsi, ho ntlafatsa ts'ebetso ea ho tšoaea lihlahisoa tsa batch le ho thusa ho khothaletsa morethetho oa tlhahiso.

④ E khona ho ikamahanya le maemo

E ka ikamahanya le lisebelisoa tse fapaneng le libopeho tsa li-workpieces bakeng sa ho tšoaea, 'me e khona ho tšoaea li-workpieces tse bataletseng le tse nyane tse kobehileng tse entsoeng ka tšepe le lisebelisoa tse ling tseo e seng tsa tšepe, tse kopanang le litlhoko tsa ho tšoaea tsa linomoro tse fapaneng tsa serial.

Melemo e felletseng ea mohala oa tlhahiso

✅ Ts'ebetso e ikemetseng ka botlalo: e fokotsa ho kenella ka letsoho le ho fokotsa kotsi ea liphoso.

✅ Taolo e nepahetseng e phahameng: tlhahlobo e tiileng ea boleng boemong bo bong le bo bong ho netefatsa hore bohloeki ba li-block tsa silevera ke ≥ 99.99%.

✅ Flexible le scalable: li-parameter tse feto-fetohang ho ikamahanya le litlhaloso tse fapaneng (1kg / 5oz / 100g, joalo-joalo) ea tlhahiso ea li-block tsa silevera.

✅ E lumellana le maemo a machaba: e fihlela litlhoko tsa setifikeiti sa indasteri joalo ka ISO.

sephetho

Mohala oa tlhahiso ea silevera ea Hasung e se e le tharollo indastering ea tšepe ea bohlokoa, ka lebaka la granulator e sebetsang hantle ea granulator, ho etsoa ka nepo ha mochini oa vacuum ingot casting, tlhaiso e hlakileng ea mochini o hatisang, le ts'ebetso e felletseng ea mochini o tšoaeang nomoro ea serial. Ho sa tsotellehe hore na ho tsetela licheleteng tsa silevera, lisebelisoa tsa silevera tsa indasteri, kapa likoleke tse phahameng, mohala ona oa tlhahiso o ka fana ka lihlahisoa tse tsitsitseng le tsa boleng bo phahameng ba li-block tsa silevera.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ke khamphani ea boenjiniere ba mechini e fumanehang ka boroa ho Chaena, motseng o motle le o holang ka potlako ka ho fetisisa moruong, Shenzhen. Khamphani ke moetapele oa theknoloji lefapheng la lisebelisoa tsa ho futhumatsa le ho lahla tšepe ea bohlokoa le indasteri ea thepa e ncha.

Tsebo ea rona e matla ea theknoloji ea ho lahla ka vacuum e re nolofalletsa ho sebeletsa bareki ba indasteri ho lahla tšepe e kopantsoeng ka bongata, motsoako oa platinum-rhodium o hlokahalang ka vacuum e ngata, khauta le silevera, jj.

Mohala: +86 17898439424

E-mail: sales@hasungmachinery.com.

WhatsApp: 0086 17898439424

Aterese: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115