UHasung ungumkhiqizi womshini wokubumba nokuncibilikisa izinsimbi eziyigugu ochwepheshe kusukela ngo-2014.

I-Hasung Silver Block Casting Production Line: Isixazululo Esisebenzayo Nesinembile Sokukhiqiza I-Silver Block Manufacturing

Ulayini wokukhiqiza we-Hasung silver block casting wamukela okokusebenza okuzishintshayo okuthuthukisiwe ukuze kuqinisekiswe ukukhiqizwa okuphumelelayo nokunemba okuphezulu kusuka ezintweni ezingavuthiwe zesiliva kuya kumabhulokhi esiliva aqediwe. Wonke umugqa wokukhiqiza uhlanganisa izinto ezine eziyinhloko: i-granulator, umshini wokuphonsa we-vacuum ingot, umshini wokufaka i-embossing, nomshini wokumaka inombolo ye-serial. Isixhumanisi ngasinye sithuthukisiwe ukuze kuqinisekiswe ikhwalithi, ukunemba, nokulandeleka kwamabhulokhi ayisiliva.

1. I-Granulator : ukulungiswa okunembile kwezinhlayiya zesiliva

Umsebenzi: Hlanganisa izinto zokusetshenziswa zesiliva zibe yizinhlayiya ezinosayizi ofanayo ukuze uqinisekise ukufana ekubunjweni okulandelayo.

Izinzuzo:

① Ukusebenza kahle nokonga amandla

Ngokwamukela idizayini yesikulufu esithuthukisiwe kanye nobuchwepheshe bokushisisa ngogesi, yonga amandla angu-15% kuya ku-30% uma kuqhathaniswa nezimbudumbudu zendabuko, kuyilapho igcina ukuphuma okuphezulu futhi yehlisa izindleko zokukhiqiza.

② Izinhlayiya ezifanayo nezizinzile

Ifakwe isikhunta esinembayo nezinhlelo zokusika ama-blade amaningi, iqinisekisa usayizi wezinhlayiyana ezingaguquki (enephutha elingu-± 0.1mm), ifanele izimboni ezidinga ukunemba okuphezulu, njengezemithi nokudla.

③ Ukulawula okuzenzakalelayo okuhlakaniphile

I-PLC+ukusebenza kwesikrini sokuthinta, ukuqapha ngesikhathi sangempela izinga lokushisa, isivinini kanye neminye imingcele, i-alamu yephutha elizenzakalelayo, ukunciphisa ukungenelela okwenziwa ngesandla, nokuthuthukisa ukusebenza kahle kokukhiqiza.

④ Ihlala isikhathi eside futhi kulula ukuyinakekela

Izingxenye ezibalulekile (izikulufu, imiphongolo) ziphathwa ngama-alloys angagugi noma ama-coatings okuphila isikhathi eside. Idizayini ye-modular yenza ukulungisa kube lula futhi kunciphisa isikhathi sokuphumula.

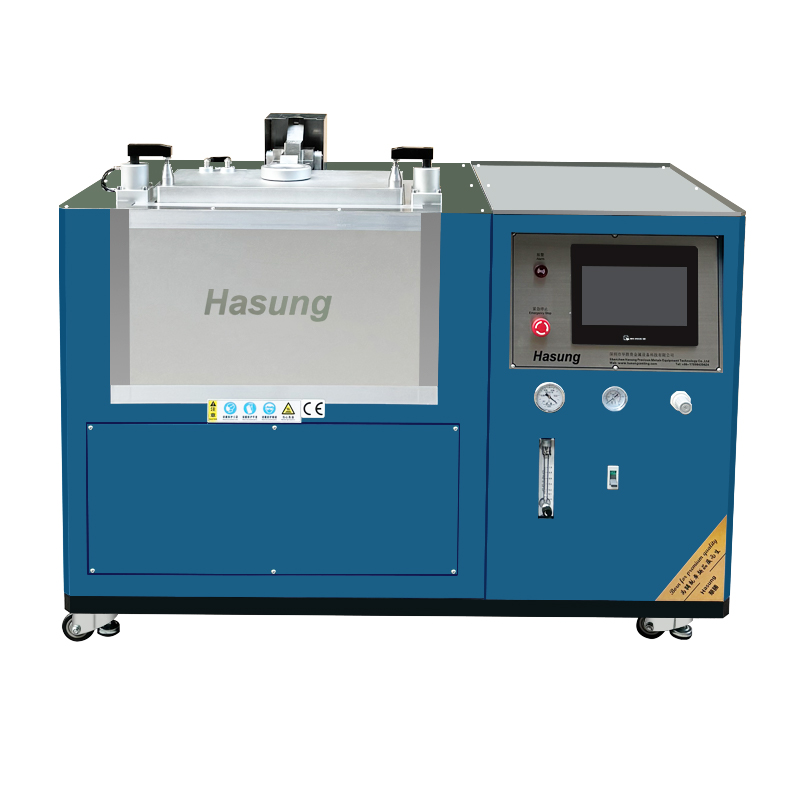

2. Umshini Wokusakaza we-Vacuum Ingot : Ukudala Amabhulokhi Esiliva Ahlanzekile

Umsebenzi: Ncibilikisa bese uphonsa izinhlayiya zesiliva zibe amabhulokhi esiliva abushelelezi, angahlanzekile, aqinisekise ukuminyana okuphezulu kanye nokushelela kwendawo.

Izinzuzo:

① Ingot yokuhlanzeka okuphezulu

Ukwamukela ubuchwepheshe bokuncibilika kwe-vacuum, ngokuphumelelayo ukunciphisa i-oxidation nokuxubana kokungcola, okulungele ukuphonsa izinsimbi ezihlanzekile ezifana ne-titanium, i-zirconium, nama-alloys akhethekile, ukuqinisekisa izakhiwo zezinto ezibonakalayo ezizinzile.

② Isakhiwo sekristalu esilinganayo

Isistimu yokulawula izinga lokushisa enembile, ehlangene nobuchwepheshe bokuqinisa isiqondiso, ihlunga usayizi wangaphakathi wokusanhlamvu nesakhiwo esifanayo se-ingot, inciphisa ukuhlukaniswa, futhi ithuthukise ukusebenza kokucubungula okulandelayo.

③ Ukusebenza kahle nokonga amandla

Lungiselela idizayini yezinhlelo zokushisisa nokupholisa, wehlise ukusetshenziswa kwamandla ngo-20% kuya ku-30% uma kuqhathaniswa nemishini yokusakaza ingot evamile, kuyilapho ugcina ukusebenza kahle kokukhiqiza okuphezulu (okufana nekhono lokucubungula isithando somlilo esisodwa esingafika kumathani angu-1-5).

④ Ukulawula okuhlakaniphile okuzenzakalelayo

I-PLC+i-human-machine interface (HMI) iqapha amapharamitha afana ne-vacuum degree, izinga lokushisa, ingcindezi ngesikhathi sangempela, isekela ukurekhodwa kwedatha nokulandelela inqubo, inciphisa amaphutha abantu, futhi yenza ukusebenza kube lula.

3. Umshini wokugqamisa: ukuphrinta kwephethini yokunemba okuphezulu

Umsebenzi: Shicilela amaphethini enziwe ngokwezifiso afana nelogo yomkhiqizo, isisindo, ubumsulwa, njll. ebusweni bamabhulokhi esiliva.

Izinzuzo:

① Ukugqamisa okunembayo okuphezulu

Imishini inokulawula ukucindezela okunembile kanye nesakhiwo sokusebenza esizinzile. Lapho uphrinta amabhlogo esiliva, imininingwane efana namaphethini nokumaka ingavezwa ngokucacile ngokunemba kobukhulu obuphezulu, okuqinisekisa ukuvumelana kokuphrinta kwebhlokhi yesiliva. Isibonelo, lapho wenza amabhlogo esiliva ohlamvu lwesikhumbuzo, amaphethini amahle angabuye abuyiselwe ngokunembile.

② Umsebenzi wasekhaya ophumelelayo

Ingakwazi ukuqedela ngokushesha inqubo ye-silver block stamping, ifinyeze isikhathi sokucubungula amabhulokhi esiliva ngamanye uma kuqhathaniswa nezindlela zendabuko, ithuthukise ukusebenza kahle kokukhiqizwa kweqoqo, isize amabhizinisi ukuletha ama-oda ngesikhathi esifushane, futhi ahlangabezane nesidingo semakethe semikhiqizo yesiliva.

③ Ikhwalithi ezinzile

Ingcindezi ngesikhathi senqubo yokufaka i-embossing ifana futhi ukusebenza kuzinzile. Ikhwalithi yokubukeka kwe-block yesiliva ngemuva kokufakwa kwe-embossing inhle, futhi ayithambekele ekuguqulweni, ukulimala nezinye izinkinga, okuthuthukisa isivuno semikhiqizo yesiliva futhi kunciphise ukulahlekelwa kwezindleko okubangelwa imikhiqizo enesici.

④ Ukuzivumelanisa nezimo ezihlukahlukene

Iyakwazi ukuzivumelanisa nokucaciswa okuhlukile kanye nokwakheka kwe-embossing yebhlokhi esiliva, noma ngabe izingcwecwe zesiliva ezincane, izingxenye zobucwebe besiliva ezinokwakheka okuyinkimbinkimbi, noma amabhlogo esiliva ajwayelekile, amapharamitha angalungiswa ukuze agcizelele, ahlangabezane kalula nezidingo zokukhiqiza ezahlukahlukene.

4. Umshini wokumaka inombolo ye-serial: Qinisekisa ukulandeleka

Umsebenzi: I-laser iqopha izinombolo ze-serial ezihlukile, izinsuku zokukhiqiza, izinombolo zeqoqo, nolunye ulwazi kumabhulokhi esiliva.

Izinzuzo:

① Inembile futhi icacile

Ingakwazi ukubuyisela ngokunembile izinombolo ze-serial, ngokushaya kahle ngisho nokujula kwezinhlamvu nezinombolo. Ngisho nasekusetshenzisweni kwesikhathi eside nasezindaweni eziyinkimbinkimbi, izimpawu azifiphali kalula, okuqinisekisa ukunemba kokuqashelwa kwenombolo ye-serial kanye nokwenza lula ukuphathwa kokulandeleka komkhiqizo.

② Kulula ukusebenza

Ukuhlelwa kwezinkinobho zedivayisi kunengqondo, kuhlanganiswe nesistimu yokulawula elula. Abasebenzi bangakwazi ukuqalisa kalula ngemva kokuqeqeshwa okulula, futhi bangakwazi ukusetha ngokushesha okuqukethwe kokumaka kanye nemingcele, behlise umkhawulo wokusebenza nezindleko zabasebenzi.

③ Isebenza kahle futhi izinzile

Inqubo yokumaka iyahambisana, iyakwazi ukuqeda ngokushesha ukumaka inombolo ye-serial, futhi isebenza ngokuzinza ngokuhluleka okumbalwa komsebenzi wesikhathi eside, ithuthukisa ukusebenza kahle kokumaka umkhiqizo weqoqo nokusiza ukukhuthaza isigqi sokukhiqiza.

④ Ivumelana nezimo kakhulu

Ingakwazi ukuzivumelanisa nezinto ezihlukahlukene kanye nokwakheka kwezinto zokusebenza zokumaka, futhi ingamaka ngokuzinza izinto zokusebenza eziyisicaba nezincane ezigobile ezenziwe ngensimbi nezinye izinto ezingezona ezensimbi, ezihlangabezana nezidingo zokumaka zezinombolo zesiriyeli zemikhiqizo ehlukene.

Izinzuzo eziphelele zomugqa wokukhiqiza

✅ Inqubo ezenzakalelayo ngokugcwele: yehlisa ukungenelela okwenziwa ngesandla futhi yehlisa ubungozi bamaphutha.

✅ Ukulawula ukunemba okuphezulu: ukuhlolwa kwekhwalithi okuqinile kuzo zonke izigaba ukuze kuqinisekiswe ukuthi ubumsulwa bamabhulokhi esiliva ≥ 99.99%.

✅ Iyavumelana nezimo futhi i-scalable: imingcele eguquguqukayo ukuze ivumelane nokucaciswa okuhlukile (1kg/5oz/100g, njll.) yokukhiqizwa kwebhulokhi yesiliva.

✅ Ithobelana namazinga omhlaba: ihlangabezana nezidingo zesitifiketi somkhakha ezifana ne-ISO.

isiphetho

I -Hasung silver block casting line isiyisixazululo embonini yokucubungula insimbi eyigugu, ngenxa ye-granulation ephumelelayo ye-granulator, ukwakheka okunembayo komshini wokuphonsa we-vacuum ingot, ukuhlonza okucacile komshini wokugqamisa, kanye nokulandeleka okugcwele komshini wokumaka inombolo ye-serial. Kungakhathaliseki ukuthi utshala imali emigoqweni yesiliva, izinto zesiliva zezimboni, noma okuqoqwayo okuphezulu, lo mugqa wokukhiqiza ungahlinzeka ngemikhiqizo yebhulokhi yesiliva ezinzile nekhwalithi ephezulu.

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjiniyela bemishini etholakala eningizimu yeShayina, edolobheni elihle nelikhula ngokushesha kwezomnotho, iShenzhen. Le nkampani ingumholi kwezobuchwepheshe emkhakheni wemishini yokushisa nokukhipha izinsimbi eziyigugu kanye nemboni yezinto ezintsha.

Ulwazi lwethu oluqinile kubuchwepheshe bokuphonswa kwe-vacuum lusenza sikwazi ukukhonza amakhasimende ezimboni ukuze afake insimbi exutshwe kakhulu, i-platinum-rhodium alloy edingekayo nge-vacuum ephezulu, igolide nesiliva, njll.

Ucingo: +86 17898439424

I-imeyili: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Ikheli: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115