Hasung inyanzvi yekugadzira michina yekukanda nekunyungudutsa simbi dzinokosha kubvira muna 2014.

Mutsetse wekugadzira mabhuroko esirivha eHasung: Mhinduro yekugadzira mabhuroko esirivha inoshanda uye yakarurama

Iyo Hasung sirivheri block casting yekugadzira mutsara inotora yepamusoro otomatiki michina kuti ive nechokwadi chekuita uye chepamusoro-chaizvo kugadzirwa kubva kune sirivheri zvigadzirwa kusvika kupedzwa zvidhinha zvesirivha. Mutsetse wese wekugadzira unosanganisira mana epakati michina: granulator, vacuum ingot yekukanda muchina, embossing muchina, uye serial nhamba yekumaka muchina. Imwe neimwe link yakagadziridzwa kuti ive nechokwadi chemhando, huchokwadi, uye kuteedzera kwemabhururu esirivha.

1. Granulator : chaiyo kugadzirira kwesirivheri zvimedu

Basa: Gadzira sirivheri zviwanikwa muzvikamu zvakaenzana saizi kuti ive nechokwadi chekufanana mukukandira kunotevera.

Zvakanakira:

① Kushanda uye kuchengetedza simba

Nekutora yakagadziridzwa screw dhizaini uye tekinoroji yekudziya tekinoroji, inochengetedza 15% kusvika 30% simba zvichienzaniswa neyechinyakare granulator, uku ichichengetedza yakakwira kuburitsa uye kuderedza mutengo wekugadzira.

② Uniform uye yakagadzikana zvimedu

Yakashongedzerwa nechaiyo mold uye akawanda blade ekucheka masisitimu, kuve nechokwadi chakafanana particle size (ine kukanganisa kwe ± 0.1mm), inokodzera maindasitiri anoda kunyatsojeka, semishonga uye chikafu.

③ Akangwara otomatiki kutonga

PLC + yekubata chidzitiro mashandiro, chaiyo-nguva yekutarisa tembiricha, kumhanya uye mamwe ma paramita, otomatiki kukanganisa alarm, kudzikisa kupindira kwemanyorero, nekuvandudza kugadzirwa kwakanaka.

④ Inogara uye iri nyore kuchengetedza

Izvo zvakakosha zvikamu (screws, barrels) zvinobatwa nearoyi-resistant alloys kana machira ehupenyu hurefu hwebasa. Iyo modular dhizaini inoita kuti kugadzirisa kuve nyore uye kunoderedza kuderera.

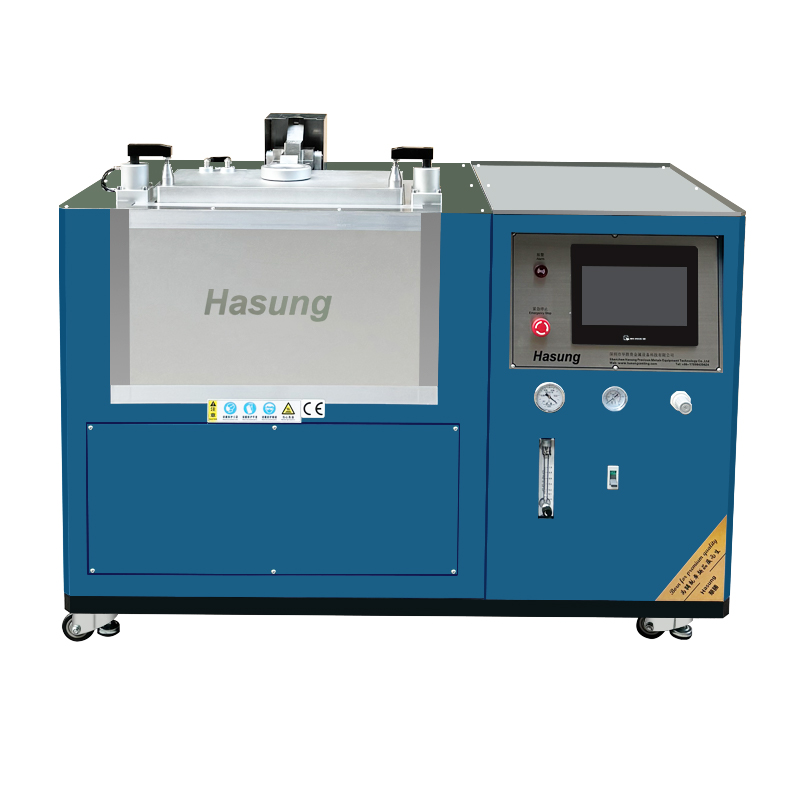

2. Vacuum Ingot Casting Machine : Kugadzira Yakakwirira Purity Silver Blocks

Basa: Nyungudusa uye kanda zvimedu zvesirivheri mune yakatsetseka, isina kuchena yemahara mabhururu esirivha, kuve nechokwadi chepamusoro density uye kutsvedzerera kwepasi.

Zvakanakira:

① High kuchena ingot

Kutora tekinoroji yekunyungudika yevacuum, inonyatso kudzikisa oxidation uye kusachena kusanganiswa, kwakakodzera kukanda yakakwira-kuchena simbi senge titanium, zirconium, uye alloys akakosha, kuve nechokwadi kugadzikana kwezvinhu zvinhu.

② Uniform crystalline chimiro

Iyo chaiyo tembiricha yekudzora sisitimu, yakasanganiswa neinongedzo yekusimbisa tekinoroji, inonatsiridza saizi yemukati yezviyo uye yunifomu chimiro cheingot, inoderedza kupatsanura, uye inovandudza inotevera mashandiro ekugadzirisa.

③ Kushanda uye kuchengetedza simba

Gadzirisa dhizaini yekudziya uye yekutonhodza masisitimu, kuderedza kushandiswa kwesimba ne20% kusvika 30% zvichienzaniswa neyechinyakare ingot yekukandira michina, uku uchichengetedza yakakwira kugadzirwa kwakanaka (senge choto chega chega chekugadzira chinosvika matani 1-5).

④ Automated hungwaru kutonga

PLC + munhu-muchina interface (HMI) inotarisisa ma paramita akadai sedhigirii rekutsvaira, tembiricha, kudzvanywa munguva-chaiyo, inotsigira kurekodha kwedata uye maitiro ekutsvaga, inoderedza kukanganisa kwevanhu, uye inoita kuti mashandiro aite nyore.

3. Embossing machine: high-precision pattern imprinting

Basa: Imprint yakagadziridzwa mapatani senge brand logo, uremu, kuchena, nezvimwewo pamusoro pemabhuru esirivha.

Zvakanakira:

① Yakanyanya kukwenenzverwa embossing

Iyo midziyo ine chaiyo yekumanikidza kutonga uye yakagadzikana yekushanda chimiro. Paunenge uchidhinda zvidhinha zvesirivheri, izvo zvakaita semapateni uye mamaki zvinogona kuratidzwa zvakajeka nehupamhi hwepamusoro huroyi, kuve nechokwadi chekuenderana kwesirivheri block imprinting. Semuenzaniso, kana uchigadzira mabhuroko esirivha ekurangarira, mapatani akanaka anogonawo kudzoreredzwa nemazvo.

② Basa rechikoro rinoshanda

Inogona kukurumidza kupedzisa sirivheri block stamping process, kupfupisa nguva yekugadzirisa yemunhu ega esirivha zvidhinha zvichienzaniswa nemaitiro echinyakare, kuvandudza batch kugadzira kugona, kubatsira mabhizinesi kuendesa maodha munguva pfupi yenguva, uye kusangana nemusika kudiwa kwezvigadzirwa zvesirivha.

③ Hunhu hwakagadzikana

Kudzvinyirirwa panguva yekugadzira embossing kwakafanana uye kushanda kwakagadzikana. Kutaridzika kwemhando yesirivha block mushure mekuisa embossing yakanaka, uye haina kukonzeresa deformation, kukuvara uye mamwe matambudziko, ayo anovandudza goho rezvigadzirwa zvesirivheri uye kuderedza kurasikirwa kwemutengo kunokonzerwa neyakakanganisika zvigadzirwa.

④ Kugadziriswa kwakasiyana-siyana

Inokwanisa kuchinjika kune akasiyana zvirevo uye maumbirwo esirivha block embossing, angave ari madiki masimbi esirivha, akaomesesa akaumbwa esirivha zvishongo, kana akajairwa mabhururu esirivha, maparamita anogona kugadziridzwa embossing, anochinjika kusangana akasiyana siyana ekugadzira zvinodiwa.

4. Serial nhamba yekumaka muchina: Ita shuwa traceability

Basa: Laser nyora yakasarudzika nhamba dzesiriri, misi yekugadzira, nhamba dzebatch, uye rumwe ruzivo pamabhuru esirivha.

Zvakanakira:

① Yakarurama uye yakajeka

Inogona kunyatso kudzoreredza serial manhamba, neakanaka sitiroko uye kunyangwe kudzika kwemavara nenhamba. Kunyangwe mukushandiswa kwenguva refu uye kwakaoma nharaunda, iwo mamarks haasi nyore kudzima, kuve nechokwadi chechokwadi chekucherechedzwa kwenhamba ye serial uye kufambisa manejimendi yekutsvaga kwechigadzirwa.

② Zviri nyore kushanda

Kurongeka kwemabhatani emudziyo kunonzwisisika, kusanganiswa neine nyore control system. Vashandi vanogona kutanga nyore nyore mushure mekudzidziswa kwakapusa, uye vanogona kukurumidza kuseta iyo yekumaka yemukati uye ma paramita, kuderedza chikumbaridzo chekushanda uye mari yebasa.

③ Inoshanda uye yakagadzikana

Iyo yekumaka maitiro inobatana, inokwanisa kukurumidza kupedzisa serial yekumaka nhamba, uye inomhanya zvakadzikama nekutadza kwenguva refu kwebasa, kuvandudza kushanda kwebatch chigadzirwa chekumaka uye kubatsira kusimudzira rhythm yekugadzira.

④ Inochinjika zvakanyanya

Inogona kuchinjika kune akasiyana zvinhu uye maumbirwo ezvishandiso zvekumaka, uye inogona kutara zvakadzikama uye madiki akakomberedzwa workpieces akagadzirwa nesimbi uye zvimwe zvisiri zvesimbi zvinhu, kusangana nekumaka zvinodiwa zveakasiyana chigadzirwa serial nhamba.

Zvakakwana zvakanakira zvekugadzira mutsara

✅ Yakazara otomatiki maitiro: inoderedza kupindira kwemanyorero uye inodzikisa njodzi yekukanganisa.

✅ Yakanyanya kurongeka kudzora: kwakasimba kwemhando yekuongorora padanho rega rega kuona kuti kuchena kwesirivha zvidhinha kuri ≥ 99.99%.

✅ Flexible uye scalable: inogadziriswa paramita kuti ienderane kune akasiyana zvirevo (1kg/5oz/100g, nezvimwewo) yesirivha block block.

✅ Inopindirana nezviyero zvepasi rose: inosangana nezvinodiwa zveindasitiri setifiketi se ISO.

mhedziso

Iyo Hasung sirivheri block casting yekugadzira mutsara yave mhinduro muindasitiri yakakosha yesimbi, nekuda kweiyo granulation inoshanda yegranulator, kunyatso kuumbwa kwevacuum ingot yekukanda muchina, kuzivikanwa kwakajeka kwemuchina we embossing, uye kuteedzera kuzere kweiyo serial nhamba yekumaka muchina. Kunyangwe kuisa mari mumabhawa esirivha, zvigadzirwa zvesirivheri zvemaindasitiri, kana kuunganidzwa kwepamusoro-soro, mutsara wekugadzira uyu unogona kupa zvakagadzika uye zvemhando yepamusoro zvigadzirwa zvesirivha block.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ikambani yeinjiniya yemakanika iri kumaodzanyemba kweChina, muguta rakanaka uye riri kukura nekukurumidza muhupfumi, Shenzhen. Kambani iyi inotungamira muhunyanzvi hwetekinoroji munharaunda yemidziyo yekudziyisa nekukanda simbi dzinokosha neindasitiri yezvinhu zvitsva.

Ruzivo rwedu rwakasimba muhunyanzvi hwekukanda vacuum runotigonesawo kushandira vatengi vemaindasitiri kugadzira simbi ine musanganiswa wakawanda, platinum-rhodium alloy inodiwa ne musanganiswa wakawanda, goridhe nesirivha, nezvimwewo.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Kero: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115